EN-5

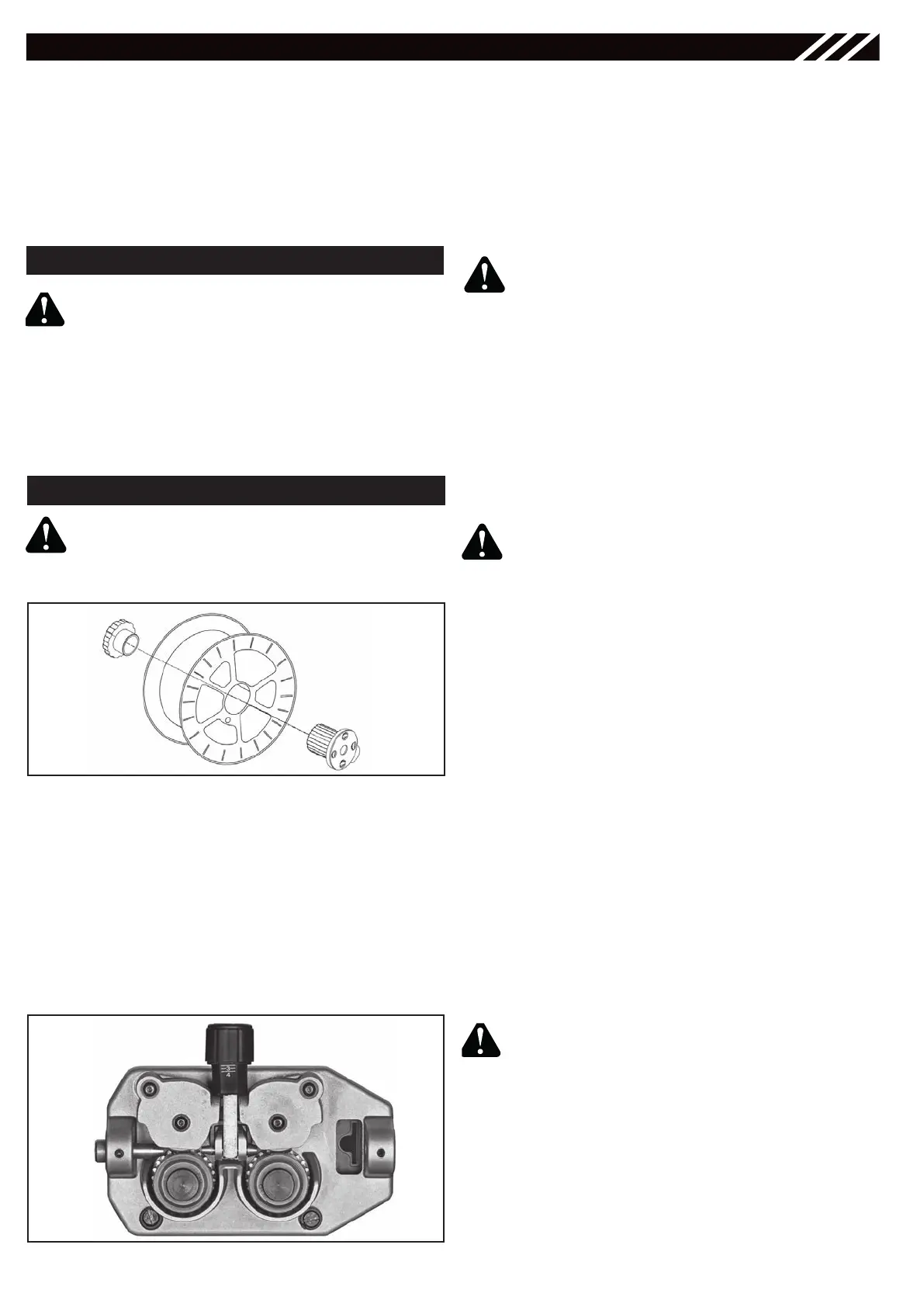

• Loosen and lower the plastic knob (A) (Figure

2). Open the pressure arm (B) of the feeder.

(Extract the wire from the torch liner if some

wire is left into the torch).

• When the wire is disconnected, grasp it with

pliers so that it cannot exit from the spool. If

necessary, straighten it before inserting it in

the wire input guide (C). Insert the wire on the

lower roll (D) and in the torch liner.

WARNING: keep the torch straight. When

feeding a new wire through the liner, make

sure the wire is cut cleanly (no burrs or an-

gles) and that at least 2 cm from the end is

straight (no curves). Failure to follow these

instructions could cause damage to the liner.

• Lower the pressure arm (B) and place the knob

(A). Tighten slightly. If tightened too much, the

wire gets locked and could cause motor da-

mage. If not tighten enough, the rolls will not

feed the wire.

WARNING: When changing the wire

diameter being used, or replacing the

wire feed roll, be sure that the correct

groove for the wire diameter selected

is inside, closest to the machine. The

wire is driven by the inside groove.

Feed rolls are marked on the side iden-

tifying the groove nearest that side.

• Close the side panel of the machine.

• Connect the power supply cable to the power

output line. Turn on the machine. Press the

torch switch. The wire fed by the wire feeding

motor at variable speed must slide through

the liner. When it exits from the torch neck,

release the torch switch.

Note: after three seconds that torch

trigger is pressed wire feeding speed

increases to allow a fast exit of the wire

on the torch neck and gas stop flowing.

• Turn off the machine.

• Mount the contact tip and the nozzle.

When checking the correct exit of the

wire from the torch do not bring your

face near the torch, you may run the risk

to be wounded by the outgoing wire. Do

not bring your fingers close to the fee-

ding mechanism when working! The

rolls, when moving, may crush the fin-

gers. Periodically, check the rolls. Repla-

ce them when they are worn and com-

promise the regular feeding of the wire.

• Refer to the Welder Base Assembly Instruc-

tions for the unit’s installation.

• Load the wire, connect the gas cylinder and

replace the wire liner if necessary following

the instructions in this paragraph.

• Check line voltage and connect power cable.

• Power the welding unit ON. The display shows

the screen of the last welding process perfor-

med by the unit.

PREPARATION FOR WELDING

EARTH CABLE AND TORCH CONNECTION

Ensure unit is powered off and unpluged

from the mains.

• Plug the torches into the sockets – A –, – B

– and – C – on the front of the welder having

care to not damage the contacts and secure

by hand screwing in the threaded connection.

• Connect the earth cable to the negative cur-

rent socket – E – of the power source.

Figure 2 - Wire Feeding Motor

• Open the side panel.

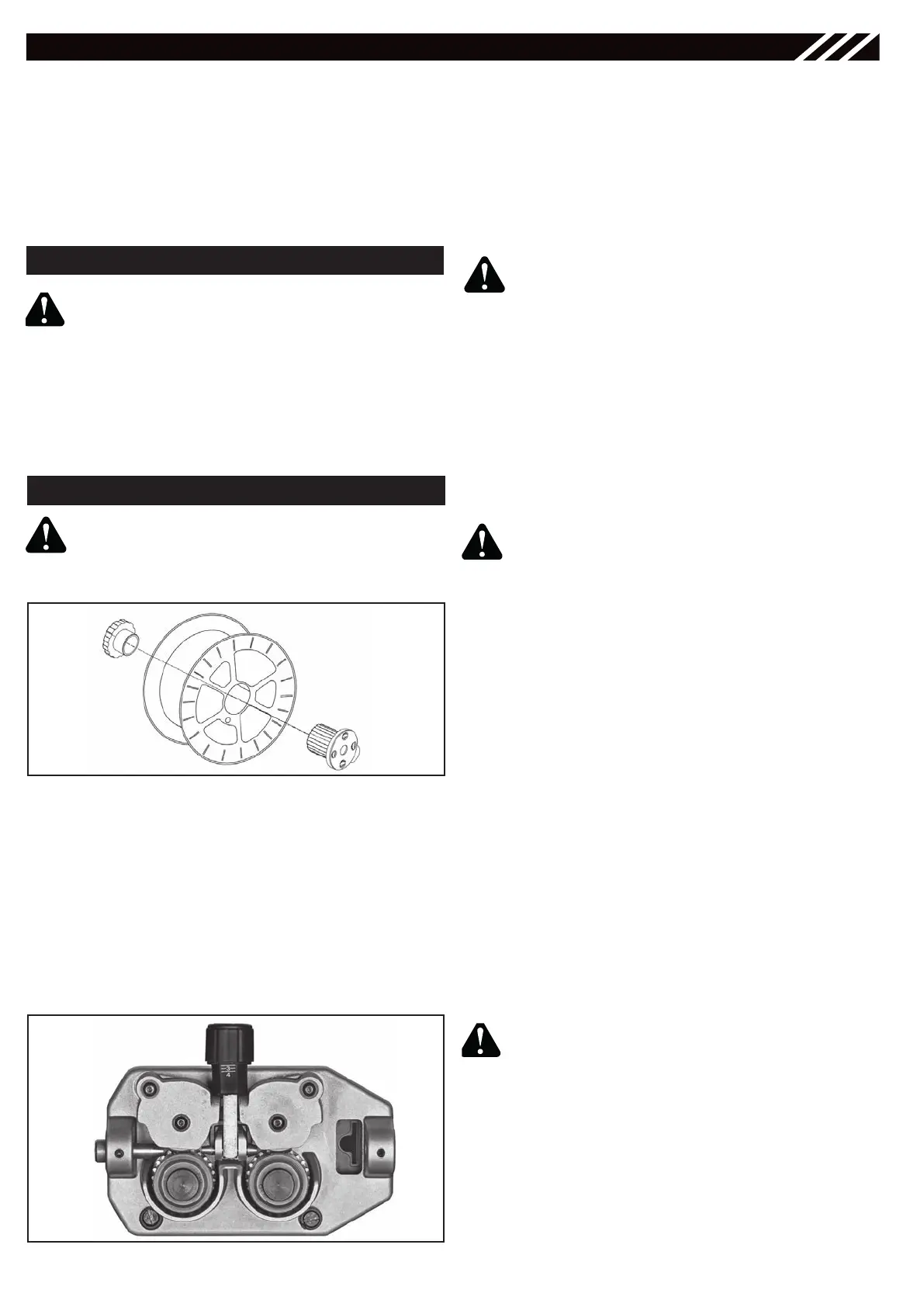

• Loosen the nut of the spool holder (brake-

drum) (Fig.1).

• Remove the plastic protection from the spool

and place the wire spool on the spool holder.

• Mount the nut.

Tighten nut to appropriate tightness.

Excessive pressure strains the wire fee-

ding motor. Too little pressure does not

allow the proper wire feeding.

Ensure the gas and electrical supplies

are disconnected. Before proceeding,

remove the nozzle and the contact tip

from the torch.

WIRE LOADING

Figure 1 - Spool Assembly

A

BB

D

D

C

Loading...

Loading...