MAINTENANCE

PERFORMER 980060 07/01/02

4-4

2. To prevent rust from building up inside the

vacuum pump (if moisture exists) we have

provided a lubrication cup on the front of the unit.

First run the unit at least 1 minute to remove any

moisture from the vacuum pump. Next, fill the

lubrication cup with WD-40, or a similar lubricant,

for 5 seconds while the unit is running and the

vacuum inlets are sealed. Do this at the end of

each working day.

3. Drain, flush and replace oil every 1500 hours or

yearly, whichever comes first. Change oil more

frequently if inspection so indicates. With AEON

PD synthetic lubricant, perform the oil change

maintenance every 4500 hours or every 2

years, whichever comes first.

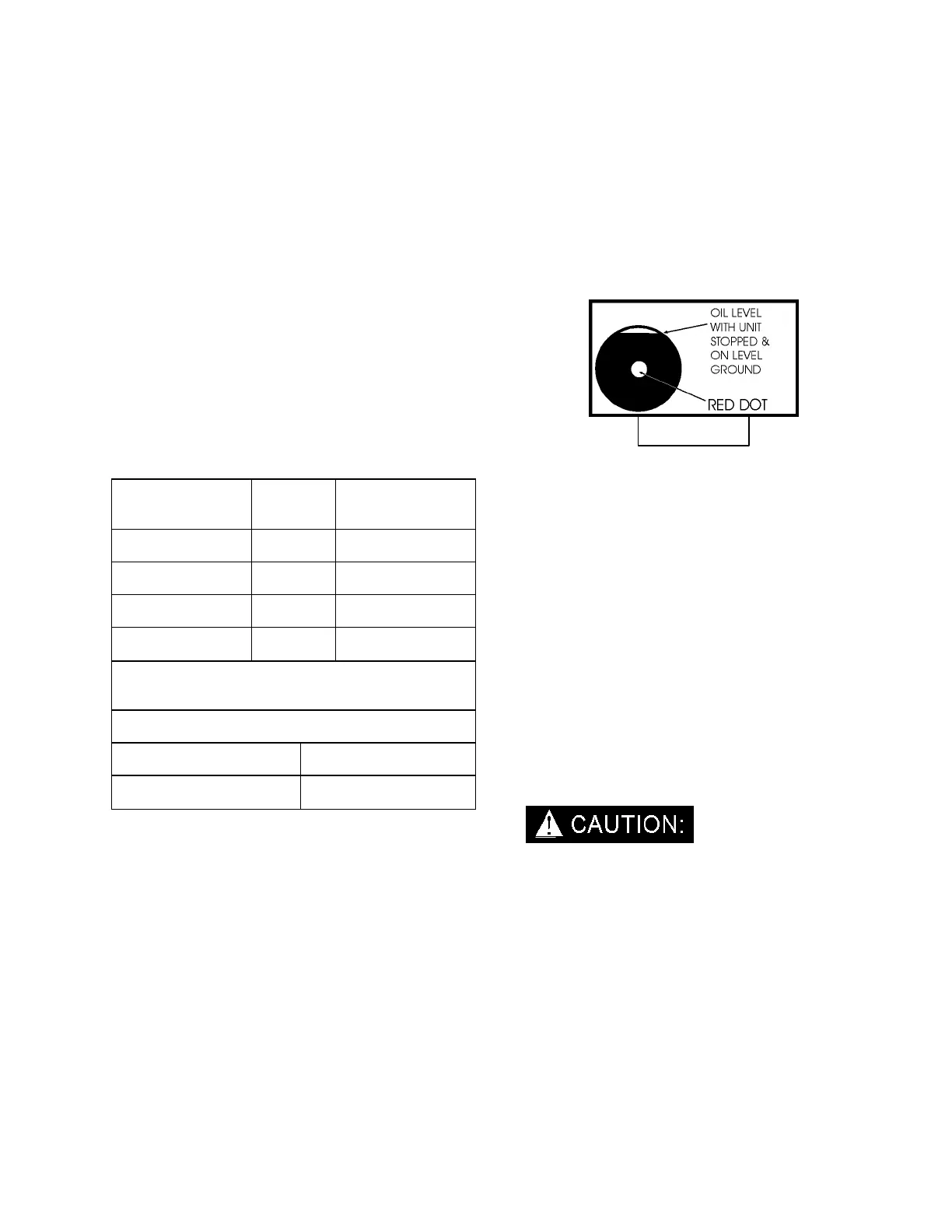

VACUUM PUMP LUBRICANT

BLOWER

DISCHARGE

TEMPERATURE

OIL

GRADE

U.S.A.

OIL VISCOSITY,

CENTISTOKES

@ 40°C

-40° TO 32°F

(-40° TO 0°C)

SAE 10W 45

32° TO 100°F

(0° TO 38°C)

SAE 20 100

100° TO 275°F

(38° TO 135°C)

SAE 40 200

OVER 275°F

(135°C)

SAE 50 250

* In applications with extreme variations in ambient

temperature a 20W-50W multiple viscosity oil is

recommended.

FOR GREASE LUBRICATED BEARINGS

Service every 500 hours or operation

Blower Discharge

Temperature

Type Grease

-40° to 275°F

(-40° TO 120°C)

Non-corrosive bearing

grease

4. The bearings on the pulley end of the vacuum

pump requires grease lubrication every 500

hours. Pack the bearings until grease comes out

of the vent holes. Use high temperature lithium

complex grease of the specification NLGI

Grade 2.

WATER PUMP

Refer to the Water Pump Operation and Service

Manual for specific instructions.

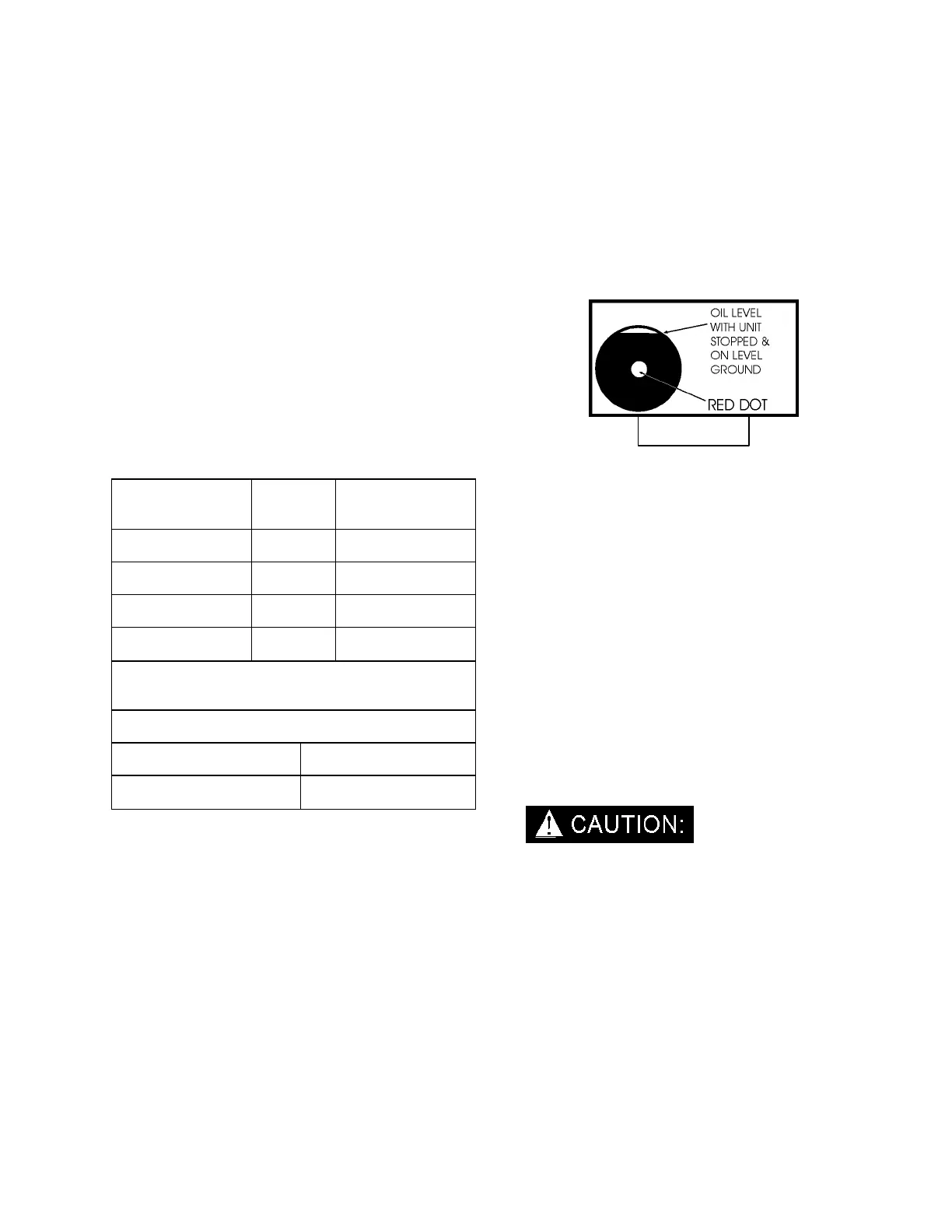

1. Check the crankcase oil level daily to assure the

proper level. Use Figure 20 as a guide when

checking the oil level. If the level has dropped,

check for the source of leakage and repair.

2. Change the crankcase oil with Cat Pump

Crankcase Oil, Part #05-008016, after the first

50 hours of operation. Drain and refill the

crankcase oil with Cat Pump Crankcase Oil

every 500 hours thereafter.

3. Other Cat approved oil equivalents are: Mobil

DTE 16, Amoco Rykow 68, and Shell Tellus T68.

VACUUM INLET FILTER

(IN WASTE TANK)

1. The vacuum filter in the waste tank should be

removed and cleaned daily. If this is done, the

filter will last for a long period of time.

2. Inspect the vacuum inlet filter inside the waste

tank. If there is any lint or debris, remove and

clean filter. Re-install the filter hand-tight.

When removing the vacuum inlet filter, grip the

plastic hexagonal section of filter. Grasping filter

by the screen may collapse or ruin the filter.

NOTE: When replacing this filter, we recommend

using a stainless steel PROCHEM filter (#14-

806518 for PERFORMER. The PERFORMER 405

requires two filters, #14-806509) only.

Loading...

Loading...