MAINTENANCE

PERFORMER 980060 07/01/02

4-14

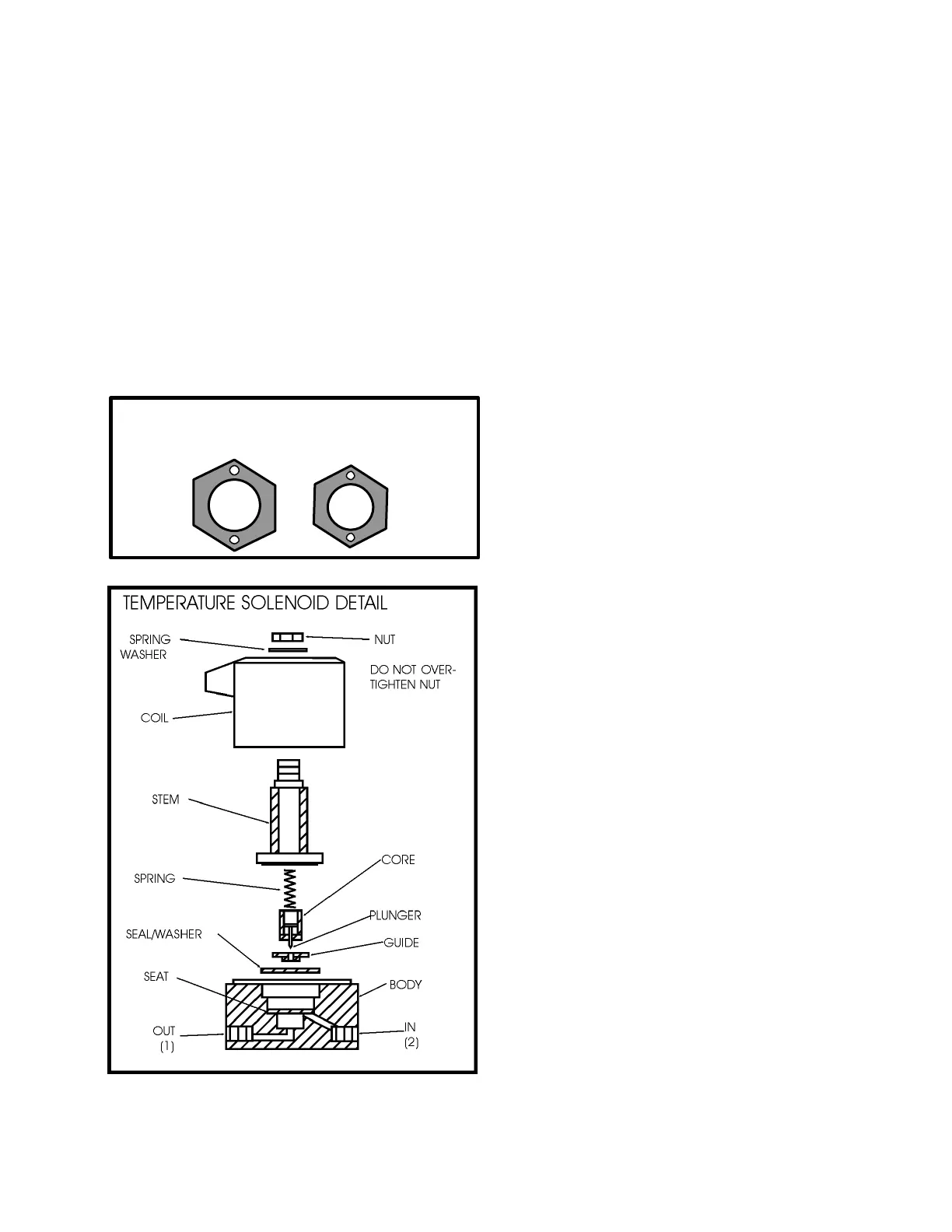

TEMPERATURE SOLENOID

The temperature solenoid may become seized due to

hard water deposits. Make certain that the core

moves freely in the stem. Also, the plunger must

move freely within the guide. Clean with #0000 steel

wool.

Check the seat to make sure that it is not distorted.

Clean the seat, using a 3/64” drill bit. ROTATE THE

DRILL BIT WITH YOUR FINGERS ONLY.

NOTE: DO NOT over-tighten nut when

re-assembling temperature solenoid. Over

tightening the nut will damage the coil.

TEMPERATURE CAPILLARY & PACKING

ASSEMBLY

INSTALLATION INSTRUCTIONS

1. Using thread sealant, thread the tapered end of

the union fitting into the thermostat manifold and

tighten.

2. Slide the jam nut over the capillary bulb with the

threaded end toward the end of the capillary bulb.

3. Insert the capillary bulb through the union fitting

and into the thermostat manifold.

4. Place the rubber seal onto the capillary tube with

the split facing 90° from the top (see the capillary

union detail).

5. Fit the four brass disks onto the capillary tube,

with two of the brass disks on each side

of the rubber seal. Face the notch on one brass

disk toward the nearby brass disk to lock the

brass disks together. Then face the notches on

the brass disks 90° from the split in the rubber

seal.

TEMPERATURE SOLENOID SERVICING

OLD STYLE

SOLENOIDS

Loading...

Loading...