MAINTENANCE

PERFORMER 980060 07/01/02

4-5

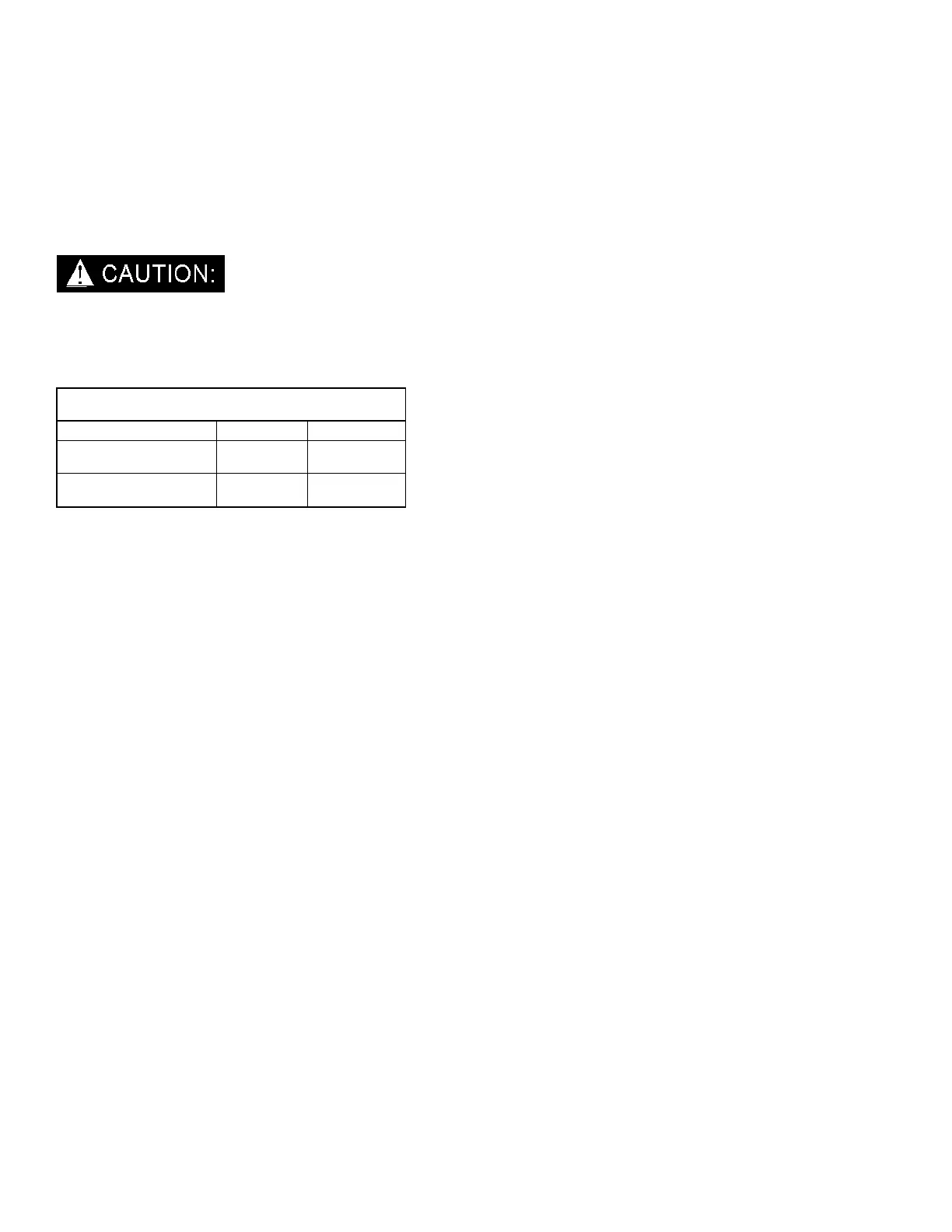

DRIVE BELTS, PULLEYS & HUBS

1. Check pulley set screws and/or hub cap screws

after the first 25 hours and then again at 100

hours. Re-torque these screws with a torque

wrench, using the values on the following chart.

Check pulley set screws and/or hub cap screws

every 500 hours thereafter.

Make certain that when you re-torque these

screws, that you use a clockwise pattern and

continue until proper torque is achieved.

TORQUE VALUES

COMPONENT INCH/LBS FOOT/LBS

Engine hub 720 60

Vacuum pump hub 192 16

2. Check for pulley groove wear, clean belts and

pulley grooves, check for worn belts, proper belt

tension, and pulley alignment after the first 25

hours and then again at 100 hours.

Check for belt ride in the groove. In multiple

groove drives, belt ride should be uniform, not

more than 1/16" above or below top of pulley

groove.

Check groove wear area for wear. Side wall of

groove should be straight, not dished out.

Bottom of groove should show no signs of belt

contact.

Inspect belts for contaminants, such as oil or

grease. Wipe belts clean with detergent and

water. Inspect pulley grooves for buildup of such

material and remove, if necessary.

Check wear surfaces of belt for excessive wear.

If they have a slick, glazed look, belts are

slipping. Check belt tension. Never replace one

belt in a used set, as used belts will elongate.

Replace entire set if replacement is necessary.

Place a straight-edge across the top of belt. There

should be no more than 1/2" deflection in the center

of the belt, halfway between the pulleys. If there is

too much slack, tighten belt, making sure that it

stays properly aligned.

See the "General Service Adjustments” section

in this manual for details.

Check alignment with straight-edge, string, or

machinist level. Correct alignment to as near perfect

as possible.

FLOAT VALVE (WATER BOX)

Check the float valve at least once a month for

proper operation. If overfilling is a problem, check

the plunger for a proper seat. Replace tip on plunger

if needed or damaged. Water level in the water box

should be about 5-1/2" to 6”.

For the procedure, see the “General Service

Adjustments” section in this manual for details.

INLET FILTER (TO WATER PUMP)

The filter inside and on the bottom of the water box

is rubber with a stainless steel screen. This should

be inspected and cleaned on a weekly basis.

Replace, if damaged.

NOTE: Vacuum all excess water and debris from

water box prior to removing strainer.

Loading...

Loading...