WARNING!

Danger of electric shock

A mains voltage may exist inside the motor or electrical ancil‐

laries.

– If the housing of the motor or electrical ancillaries has

been damaged, you must disconnect it from the mains

immediately. The pump must only be returned to service

after an authorised repair.

What requires electrical installation?

n Motor

n External fan (optional)

n Stroke control drive (optional)

n Stroke adjusting drive (optional)

n Diaphragm rupture sensor (Option)

n Stroke sensor (optional)

n Pacing relay (option)

n Frequency converter (optional)

WARNING!

EX pumps in areas at risk from explosion

– Protect drive motors with appropriate motor protection

switches. Only use motor protection permitted for this

kind of application with Ex"e" motors. (Protection against

heating from overloading)

– Ensure that motors are only installed and inspected by a

"recognisably trained" skilled operative in areas at risk

from explosion.

–

Observe the enclosed operating instructions for the Ex

motor.

CAUTION!

The motor can be damaged

Provide appropriate motor protection devices (e.g. motor pro‐

tection switch with thermal overcurrent trip) to protect the

motor against overloading.

Fuses do not provide motor protection.

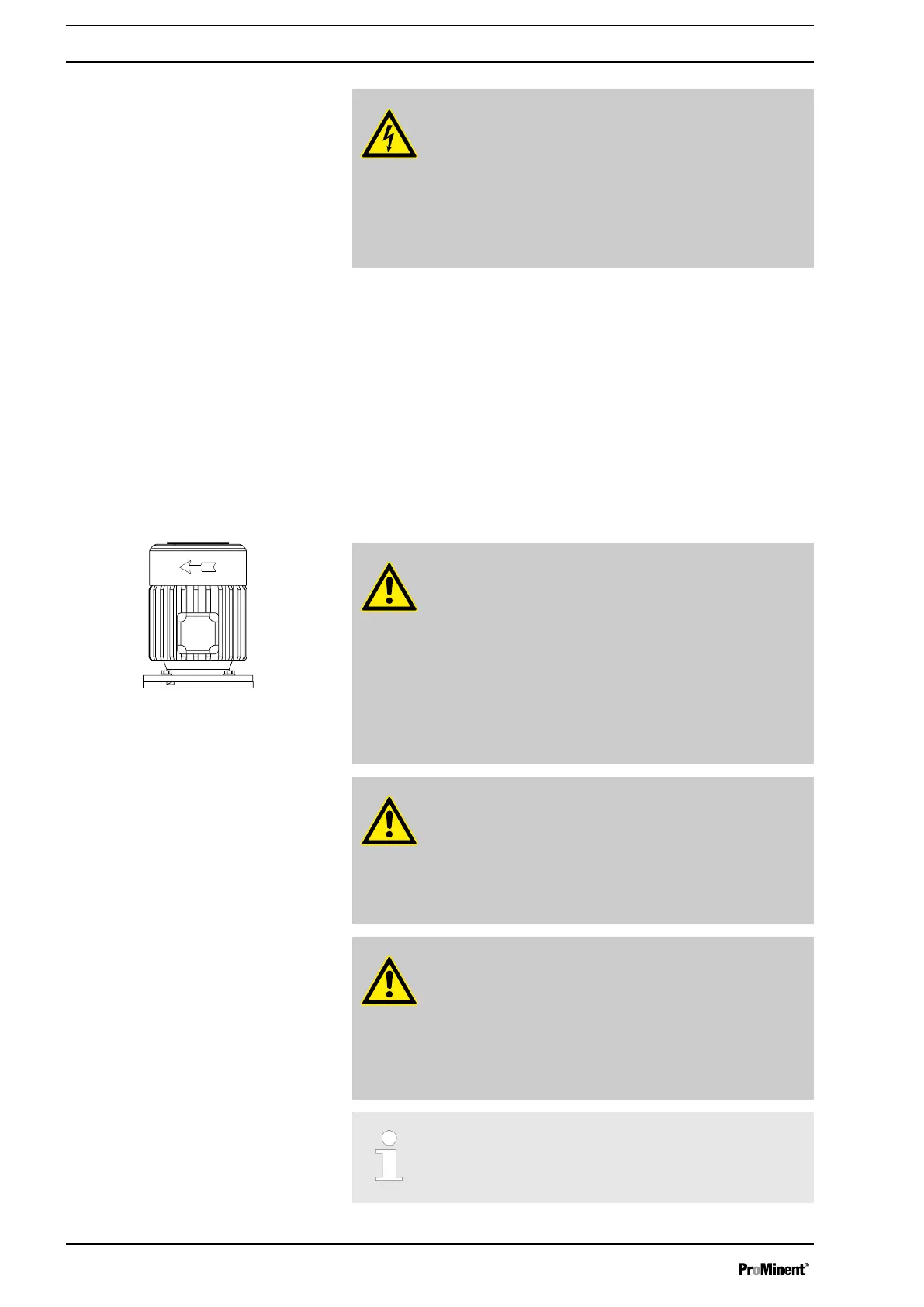

CAUTION!

The pump can be damaged

The pump can be damaged if the motor drives the pump in

the wrong direction.

– When connecting the motor, pay attention to the correct

direction of rotation indicated by the arrow on the fan

cover, as shown in Fig. 18.

Install an electrical isolating device in the mains supply

cable, e.g. a mains switch, to be able to switch off the pump

independently of the entire installation (e.g. for repair).

Motor

Fig. 18: Direction of rotation of motor

Installation, electrical

24

Loading...

Loading...