Procedure 2 – Lubricate Components after Cleaning

(with food grade lubricant)

Lubricate the shaft of the

beater bar and sealing

sleeve, then install the

sealing sleeve

Slide the O-rings into the

grooves on the piston and

lubricate

Place the door gasket of

dispensing door into the

groove on the back of the

dispensing door and

lubricate

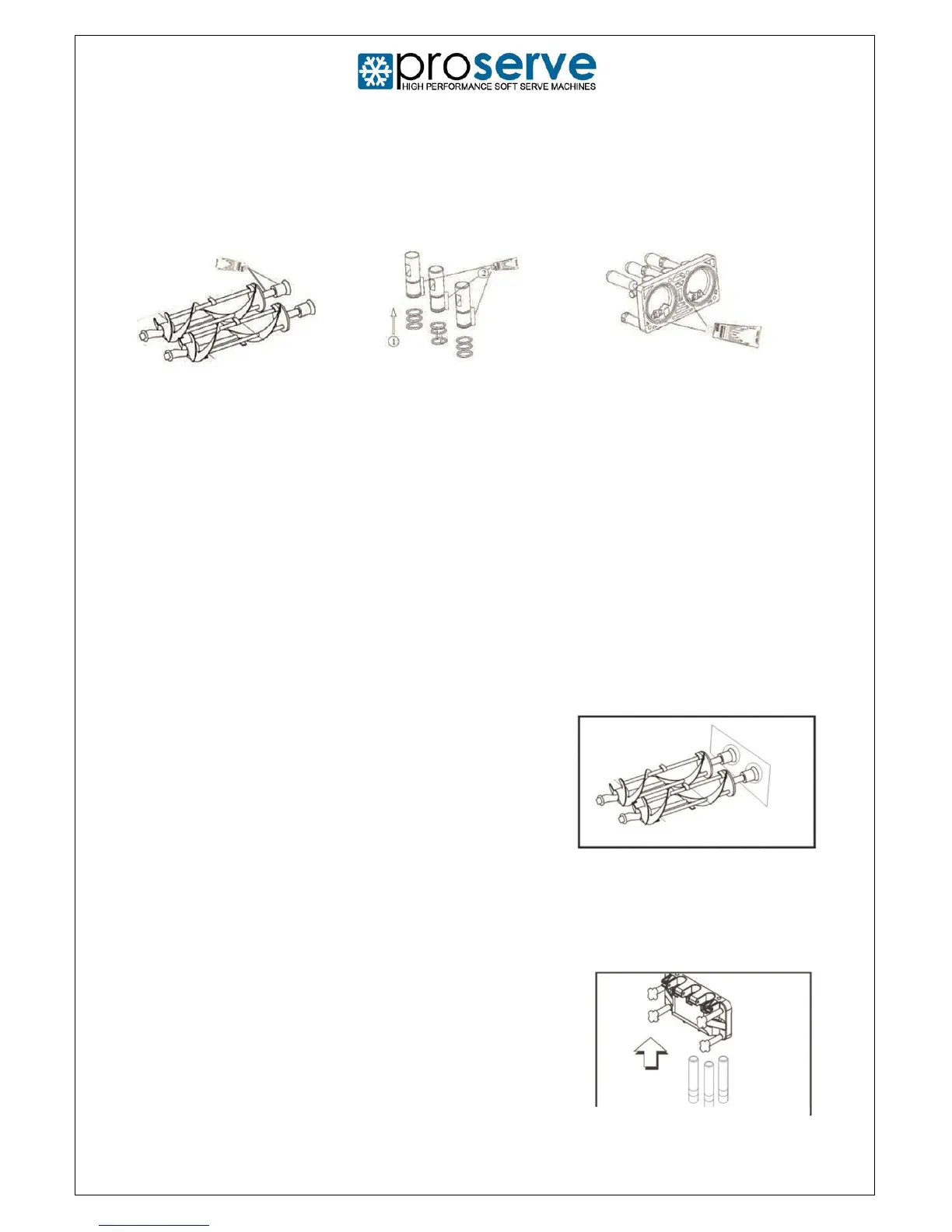

Procedure 3 – Assemble Components after Cleaning

Beater Bar Installation

Ensure the machine is turned off. Assemble and lubricate the rear end of the beater with

the sealing sleeve, add the scraper blades and push it

forward into the freezing cylinder. Align the rear end of

the beater shaft with the square socket at the back of

the freezing cylinder. Rotate the beater slightly to

correctly locate the shaft into the socket and fully push

the beater into the cylinder (Diagram 12). The shaft will

spring back slightly due to the rubber bearing at the back

of the beater bar.

Drip Tray

Make sure this is fitted correctly beneath the dispensing door.

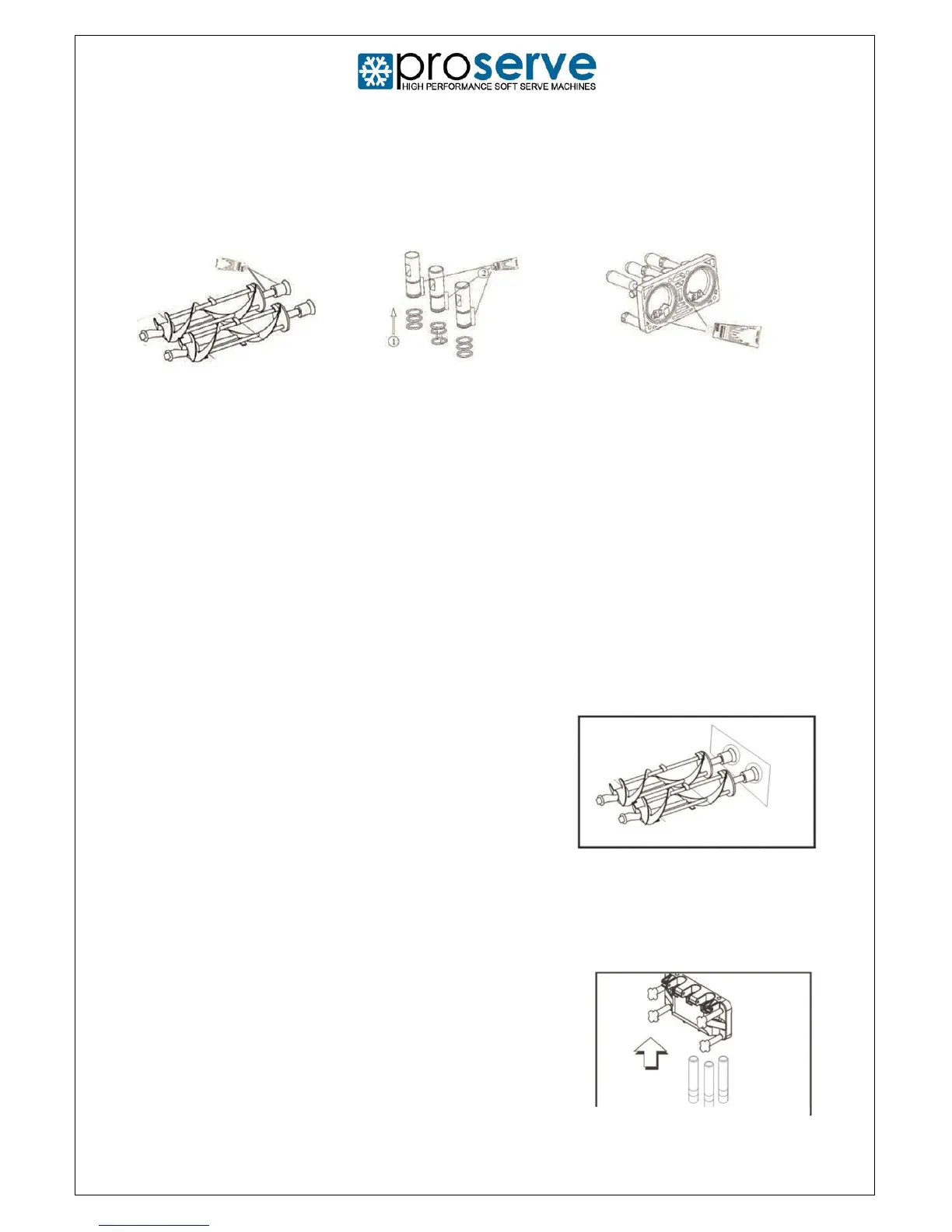

Piston Installation

Ensure the machine is turned off. First take a firm grip of

the dispenser door and insert/push up the lubricated

piston(s) with the groove for the handles facing outwards

(Diagram 13). Place the handle(s) into the groove of the

piston(s) and secure in place by inserting the fixed pin

through the holes of the dispensing door and handle(s).

Loading...

Loading...