10

Connect the Natural Gas (NG) Supply Line

Fire and explosion hazard. Never connect or disconnect the natural

gas hose while the engine is running. Do not smoke or create

sparks while handling natural gas. Always turn the engine off and

allow the generator to cool for at least ve minutes before

connecting to natural gas.

Never use a natural gas supply line, natural gas hose, or any other

fuel item that appears to be damaged.

● To reduce the risk of injury, perform a leak test any time the

natural gas hose is disconnected and reconnected.

● Explosion hazard. If you smell methane, do not start the

generator. Always completely close natural gas supply line valve

and disconnect natural gas (NG) hose from generator when not

in use.

1. Turn the generator off and allow the engine to cool for at least

ve minutes.

2. Verify that the gas is turned off at the natural gas supply line.

Preparation

NOTICE

WARNING

● All new propane tanks must be purged of air and moisture prior to

lling. Used propane tanks that have not been plugged or kept

closed must also be purged. The purging process should be done

by a propane tank supplier (propane tanks from an exchange

supplier should have been purged and lled properly).

● ALWAYS position the propane tank so the connection between the

valve and the gas inlet will not cause sharp bends or kinks in the

hose.

Explosion hazard. DO NOT start generator if you smell propane.

ALWAYS fully close the propane tank valve and disconnect the LPG

hose from the generator when not in use.

1. Turn the generator OFF and place on a at surface in a well ventilated

area.

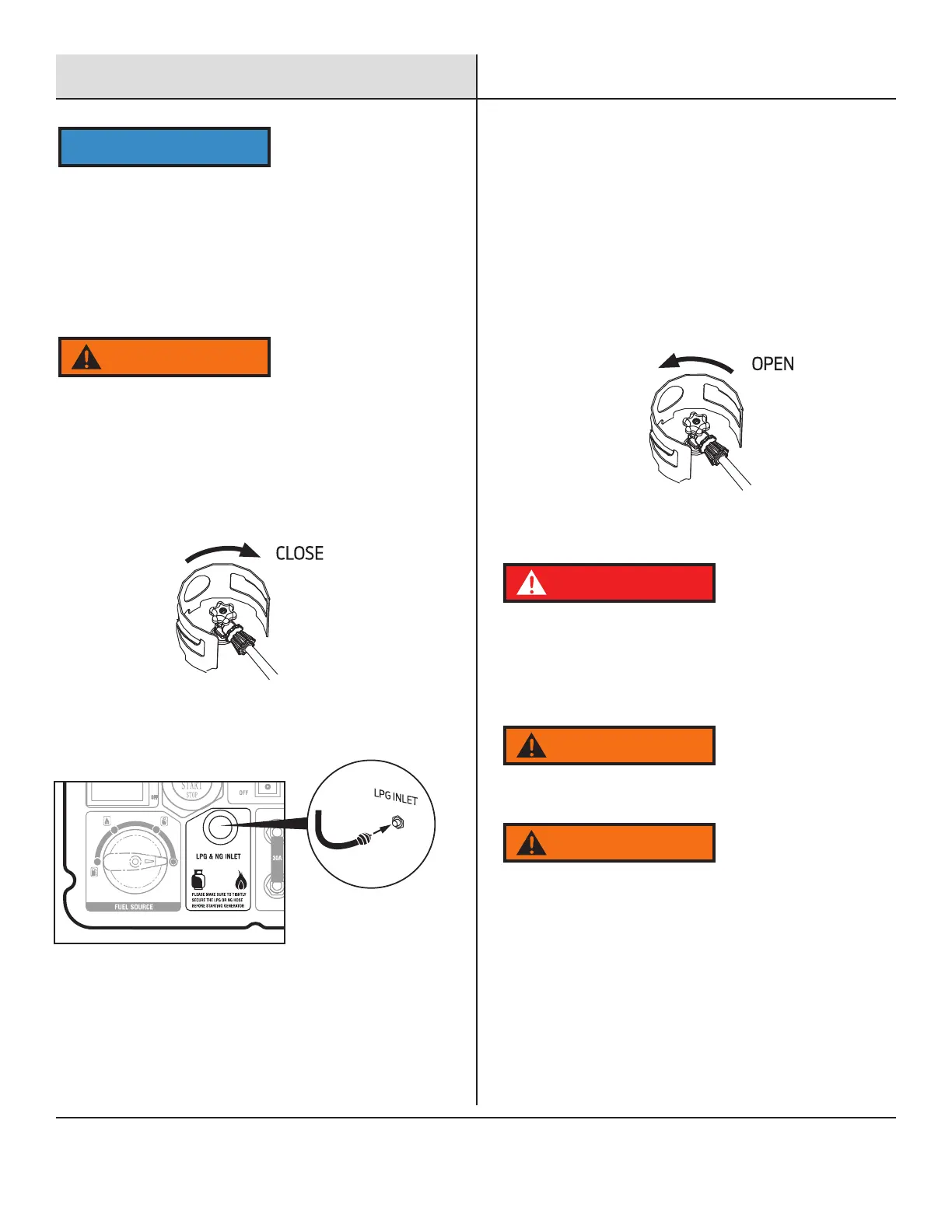

2. Verify that the propane tank valve is in the fully closed position.

3. Remove the cover on the generator propane/natural gas inlet.

4. Use your ngers to hand thread the LPG hose (included) to the

propane inlet on the generator.

IMPORTANT: DO NOT use thread seal tape or any other type of sealant to

seal the LPG hose connection.

5. Tighten the LPG hose connector with an adjustable wrench until it is

snug. DO NOT over tighten.

6. Remove the safety plug or cap from the propane tank valve and attach

the other end of the hose to the LPG connector on the tank. hand-tighten.

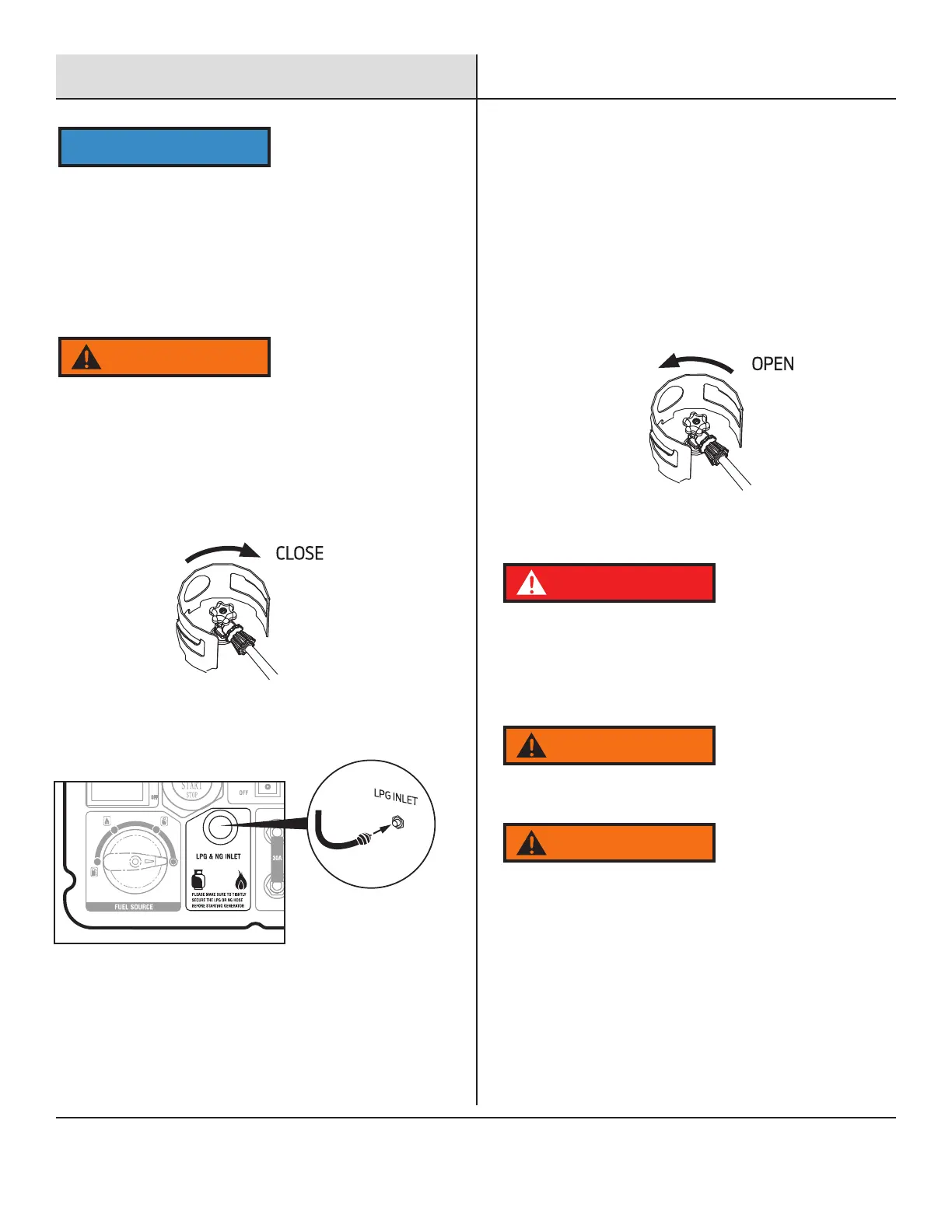

7. Turn the propane tank valve to the fully open position. Check all

connections for leaks by wetting the ttings with a solution of soap and

water. Bubbles which appear or bubbles which grow indicate that a leak

exists. If a leak exists at a tting, turn the propane tank valve to the

fully closed position and tighten the tting. Open the propane tank valve

and recheck the tting with the soap and water solution. If the leak

continues or if the leak is not at a tting then DO NOT use the generator

and contact an authorized Pulsar service center.

DANGERDANGER

WARNING

WARNING

Loading...

Loading...