11

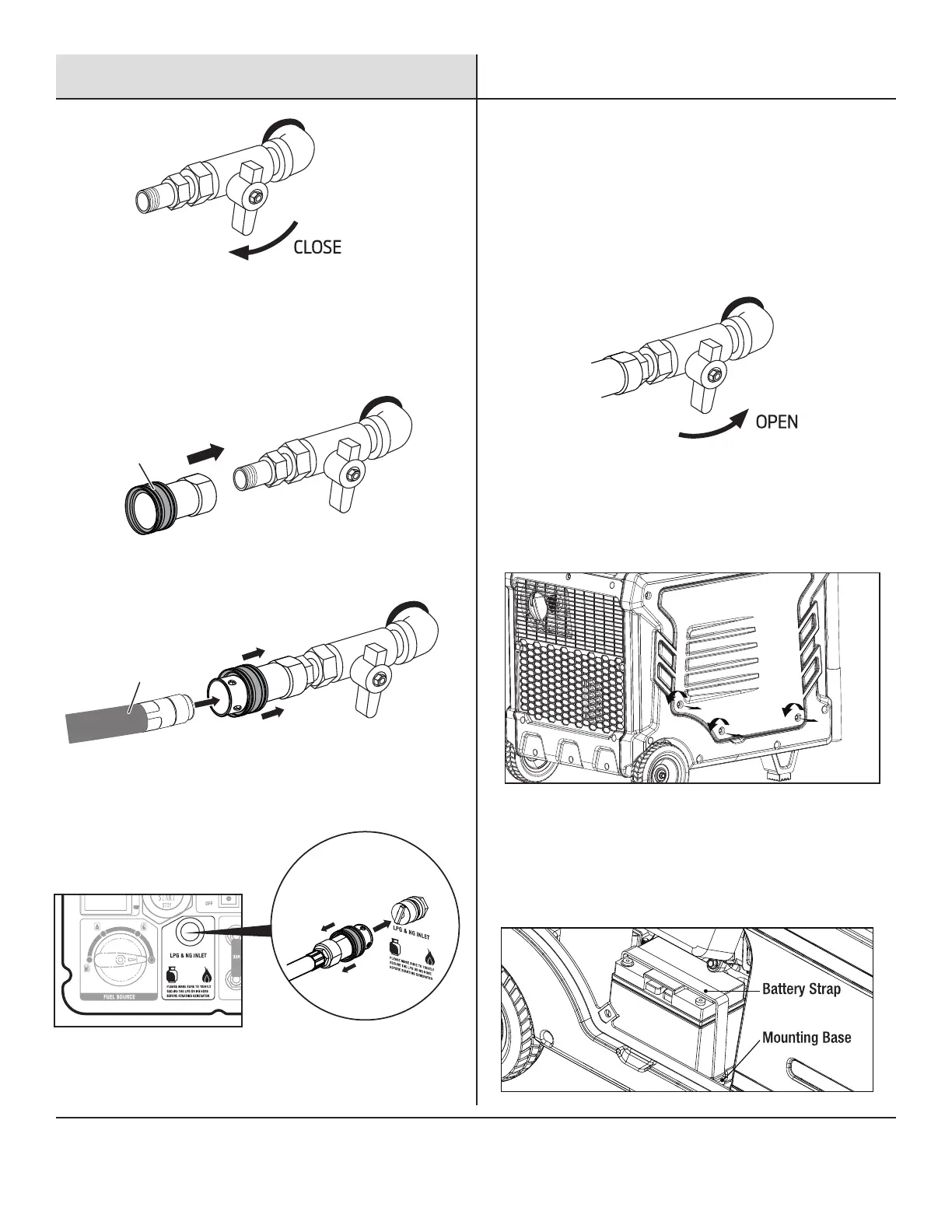

3. Completely unwrap and straighten the natural gas hose to

prevent kinks.

4. Contact your local gas company for guidance on accessory

connection to a natural gas line. You qualied contractor must

minimally ensure the pipe supply line threads are clean and in

good condition. Pipe connections must be made using a gas

rated 'dope' or PTFE tape.

5. Pull the quick connect collet rearward, insert the natural gas hose

nipple, then release the collet; ensure a solid connection is made.

6. Push back the quick connector collet of the natural gas hose, insert it

into the generator propane/methane inlet, loosen the quick connector

sleeve, and make the sleeve clamp the propane/methane inlet.

Natural Gas Adapter

Natural Gas Hose

IMPORTANT: DO NOT use thread seal tape or any other type of sealant to

seal the natural gas hose connection.

7. Turn the natural gas (NG) supply line valve to the fully open

position. Check all connections for leaks by wetting the ttings with

a solution of soap and water. Bubbles which appear or bubbles

which grow indicate that a leak exists. If a leak exists at a tting,

turn the natural gas (NG) supply line valve to the fully closed

position and tighten the tting. Open the natural gas (NG) supply

line valve and recheck the tting with the soap and water solution. If

the leak continues or if the leak is not at a tting then DO NOT use

the generator and contact an authorized Pulsar service center.

Preparation

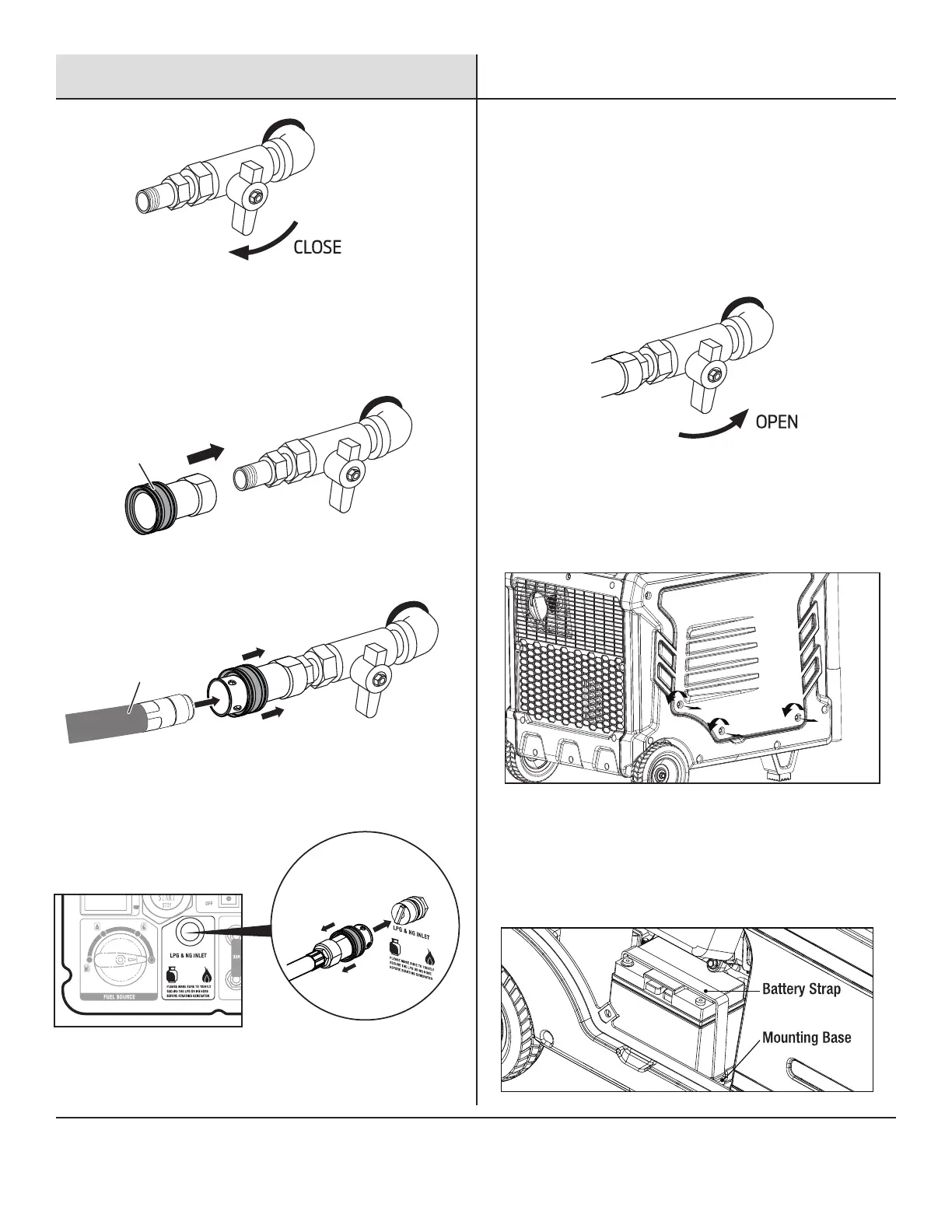

Connecting The Battery

1. On the left side of the generator, loosen the screws and remove the

cover.

2. Verify that the rubber battery strap is rmly securing the battery in

place. If loose, pull on the strap and hook it onto the mounting base.

Note: If the strap is loose behind the battery, remove the battery,

reconnect the strap, replace the battery, then thread the strap under

the battery quick-connect cables.

Loading...

Loading...