48

7300-M009-0_R

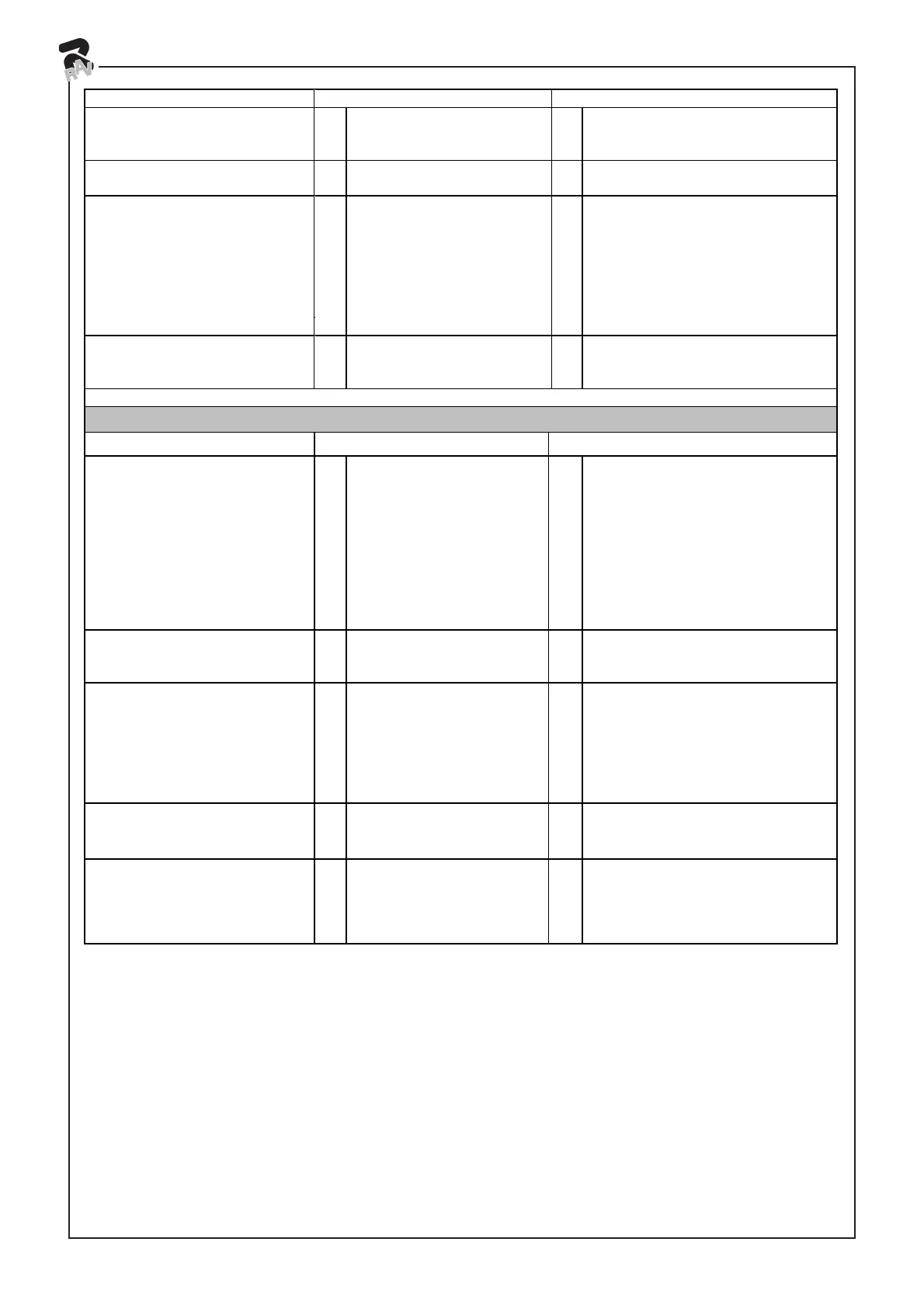

PROBLEMS CAUSES REMEDIES

The head gets in contact with

the rim during assembly/disas-

sembly.

a)

b)

Clamping plate not adjusted

or faulty.

Spindle retaining screw loose.

a)

b)

Adjust or replace the clamping plate.

Tighten the screw.

One or more pedals do not

return to their original position.

a)

b)

Return spring released.

Return spring broken.

a)

b)

Fasten the spring.

Replace the spring.

a)

b)

Machine pneumatic system

not connected.

Air lines clogged.

a)

b)

Check pneumatic connections and

supply.

Ensure that the air filter is clean and

undamaged, if fitted. If no air filter is

fitted, remove all dirt into the

pneumatic system and then fit a

suitable filter.

Pneumatic controls do not

work (chucking, beader, post

tilting and tool clamping).

c)

Silencers dirty or clogged.

c)

Clean and/or replace the silencers.

Some single pneumatic devices

do not work (beader, clamps or

post tilting device).

a)

Ensure that device and/or

distributor seals are not

damaged.

a)

Call After-Sales Service.

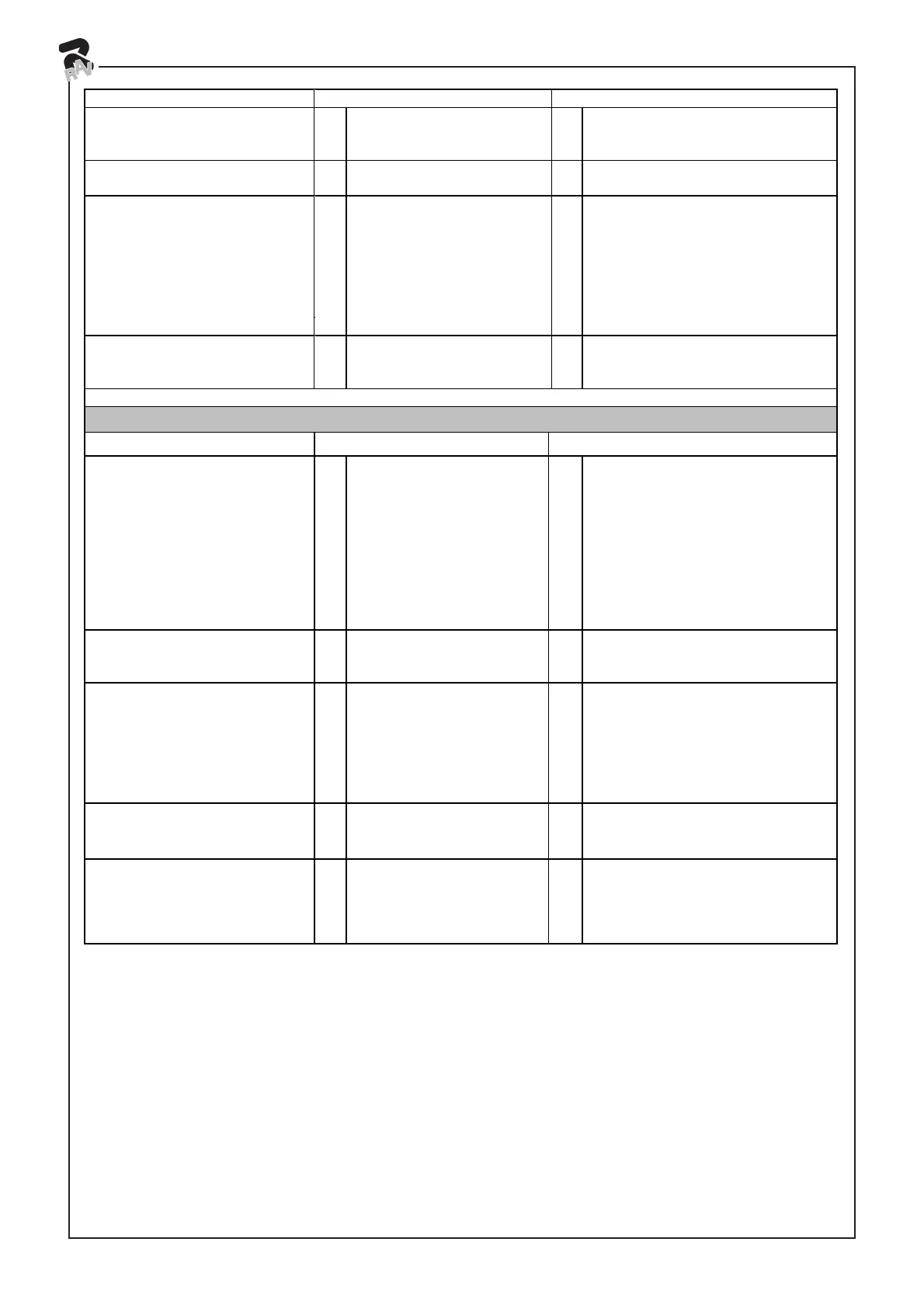

ONLY FOR G7645D.XX_G7645ID.XX_G7645ITD.XX MODELS

PROBLEMS CAUSES REMEDIES

a)

Inverter overload alarm

Or

Inverter undervoltage alarm

Or

Inverter overvoltage alarm

a)

If an extension lead is used leading

to the machine, shorten its length or

increase the cross section of the

conductors (disconnect and re-

connect). Lift the motor pedal and

wait for automatic resetting.

The.spindle does not turn.

b)

Overheating alarm

b)

Wait for the motor system to cool

down (the machine will not start if the

temperature does not drop below the

set safety limit).

The.spindle does not turn in

the counter clockwise

direction.

a)

The pedal unit microswitchis

broken

a)

Replace the microswitch

1. Leave the motor pedal in the idle

position.

2. Leave the machine connected to

the mains.

The spindle turns slowly even

though the motor pedal is not

being pressed.

a)

Reversible decalibration of

the pedal unit

a)

3. Wait 30 seconds for the automatic

attempt at recalibrating the pedal unit

to finish.

The.spindle does not turn but

attempts to when the machine

is turned back on.

a)

Irreversible decalibration of

the pedal unit

a)

Contact assistance.

The spindle does not reach

maximum rotation speed.

a)

Mechanical resistance of the

gear motor has increased

a)

Make the spindle turn with no-load

for a few minutes so the system can

warm up thus reducing friction.

If the spindle does not re-accelerate

after this then call assistance.

Loading...

Loading...