17 | P a g e

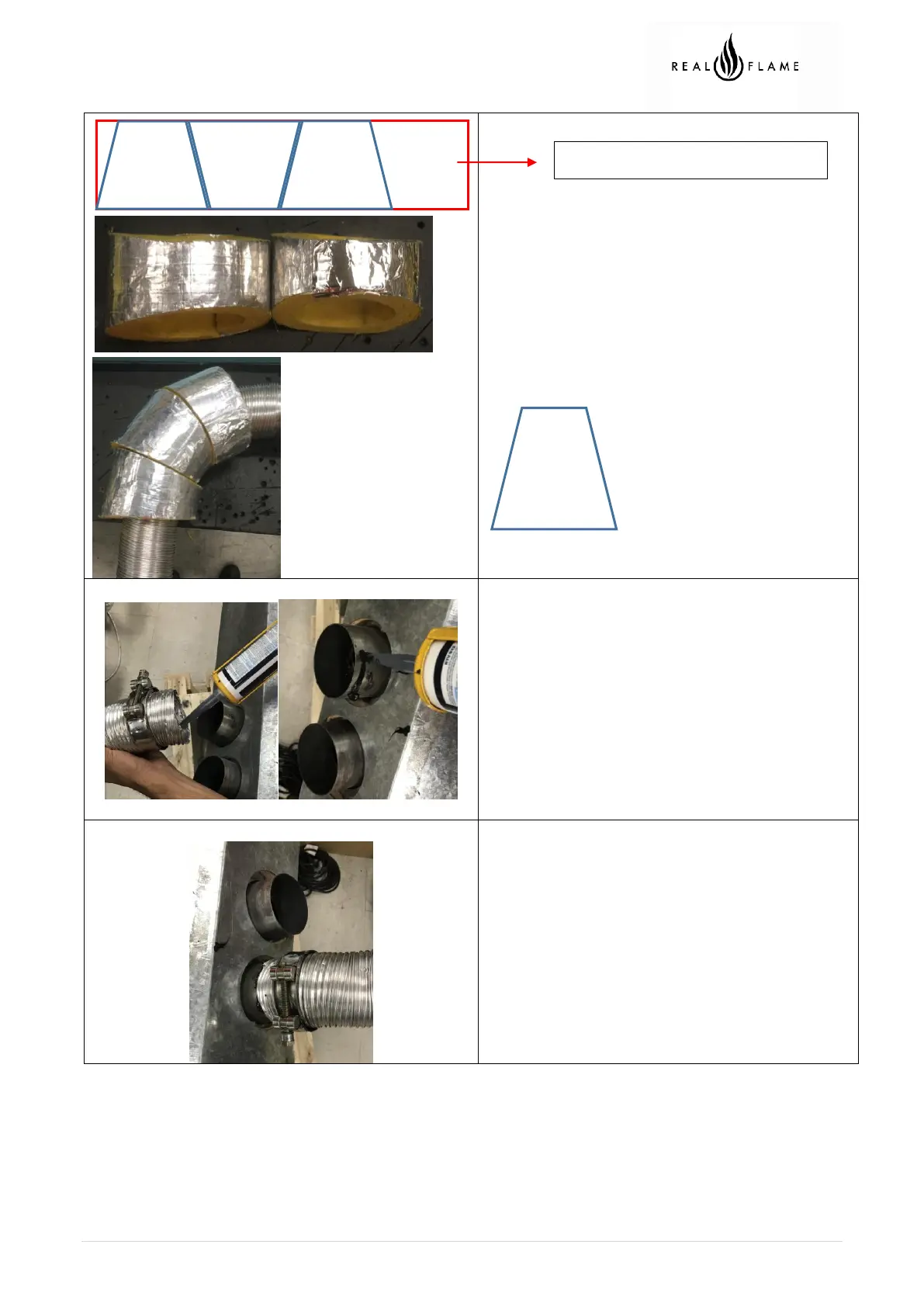

For 90° and 45° bends the corners must be

insulated.

For a 90˚ bend with a minimum bend radius is

150mm. Cut the insulation diagonally into 3 pieces

in a cone shape.

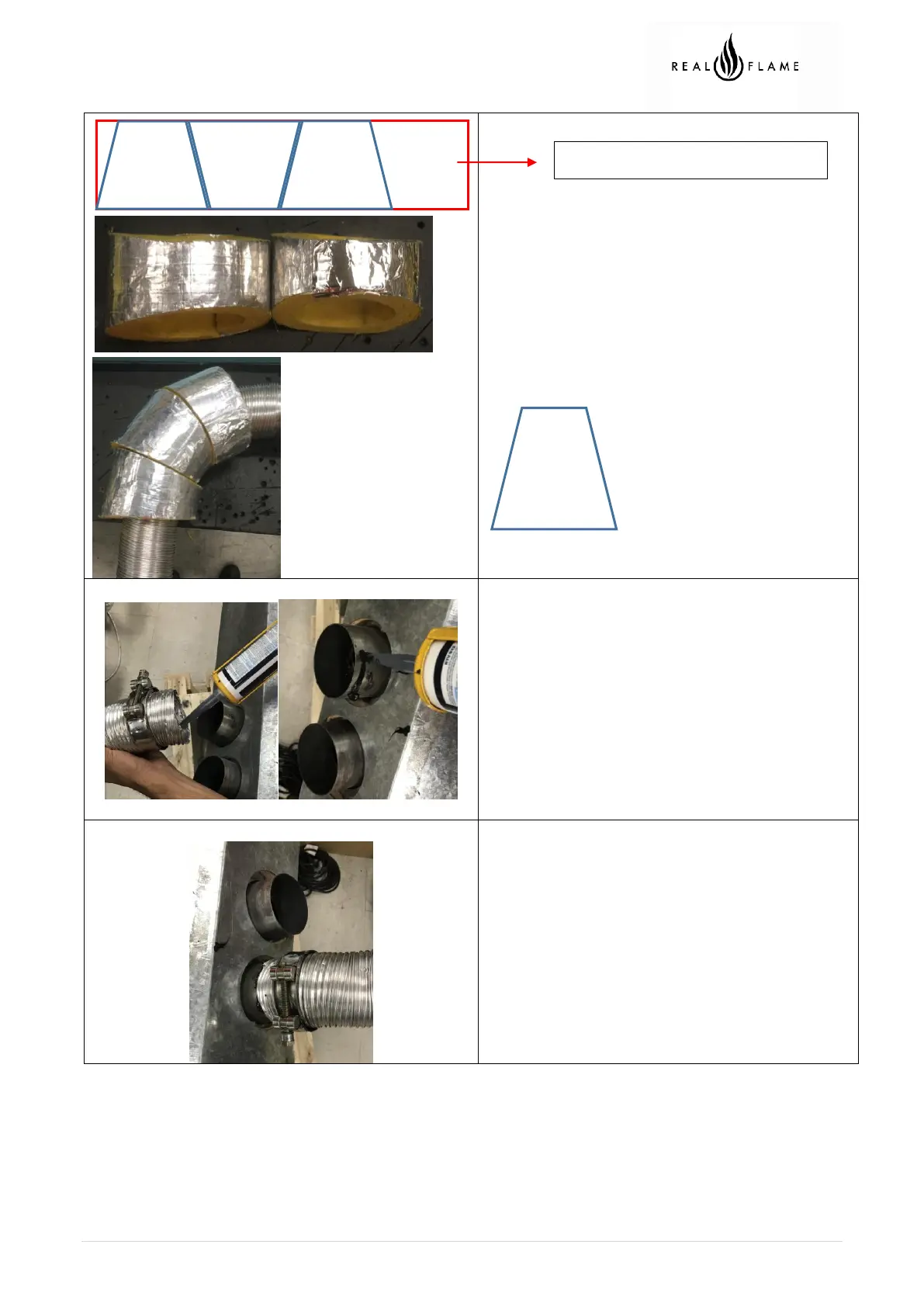

On the heater connection end - Fit clamp loosely &

apply silicon inside the pipes. Apply an 8mm silicon

bead fully around the inside of the flue and on the

heater spigot. Smear the silicon around the spigot

and pipe.

Recommended Silicon – Non-acetic, neutral cure

200°C or higher temperature rated. Bostik RTV 922

or similar

Slide flue onto connection spigot fully. Tighten

clamp fully. Wipe excess silicon, visually check

connection to ensure connection is fully sealed.

Repeat above with air intake flue pipe to heater

connection.

Clip flues as required to provide adequate support.

Insulation cut pattern for 90° bend

Loading...

Loading...