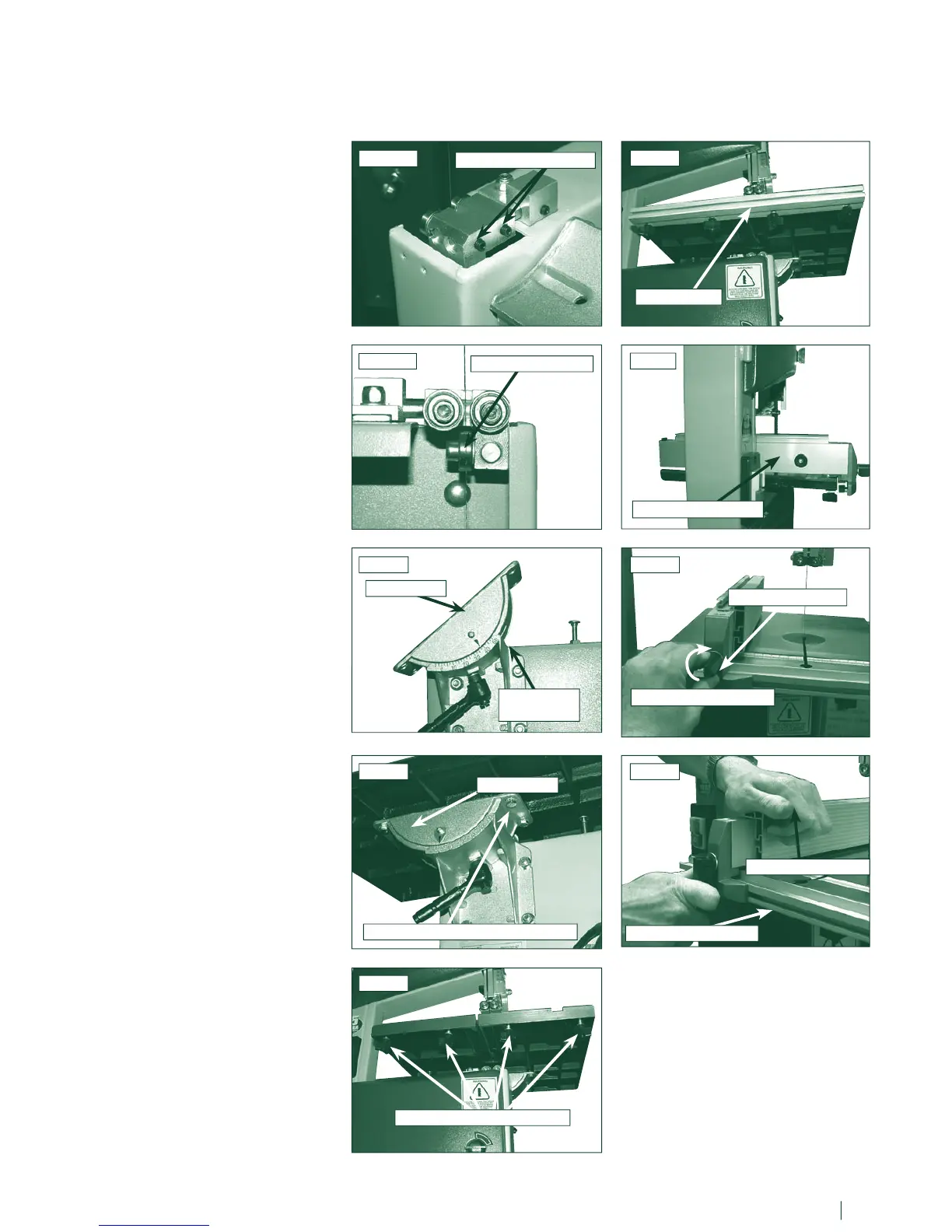

4. Machine Assembly - cont.

Fig.4.1B

THRUST BEARING

Fig.4.3

TRUNNION

TABLE FIXING BOLT & WASHER

12 13

At this stage it is advisable to make an

initial setting in the lower blade guides,

slacken the two left hand side grub

screws

Fig.4.1A, then position the guide

assembly so the blade runs centrally on

the thrust bearing

Fig.4.1B.

4.1 Fitting the table

Attach the trunnion to the trunnion carrier

with the ratchet handle supplied

Fig.4.2.

Adjust the trunnion until it is level and fit

the table using the four table bolts and

serrated was

hers Fig.4.3.

Caution

It may be necessary to seek

assistance with this as the table is

heavy and will not be stable until

bolted down.

4.2 Fitting the fence rail

Take the four star knobs and was

hers

and fit them into the threaded holes on

the underside of the table

Fig.4.4. But do

not fully tighten.

Slide the fence rail into the gap left

between the table and the star knobs

then tighten the star knobs to secure the

fence rail

Fig.4.5.

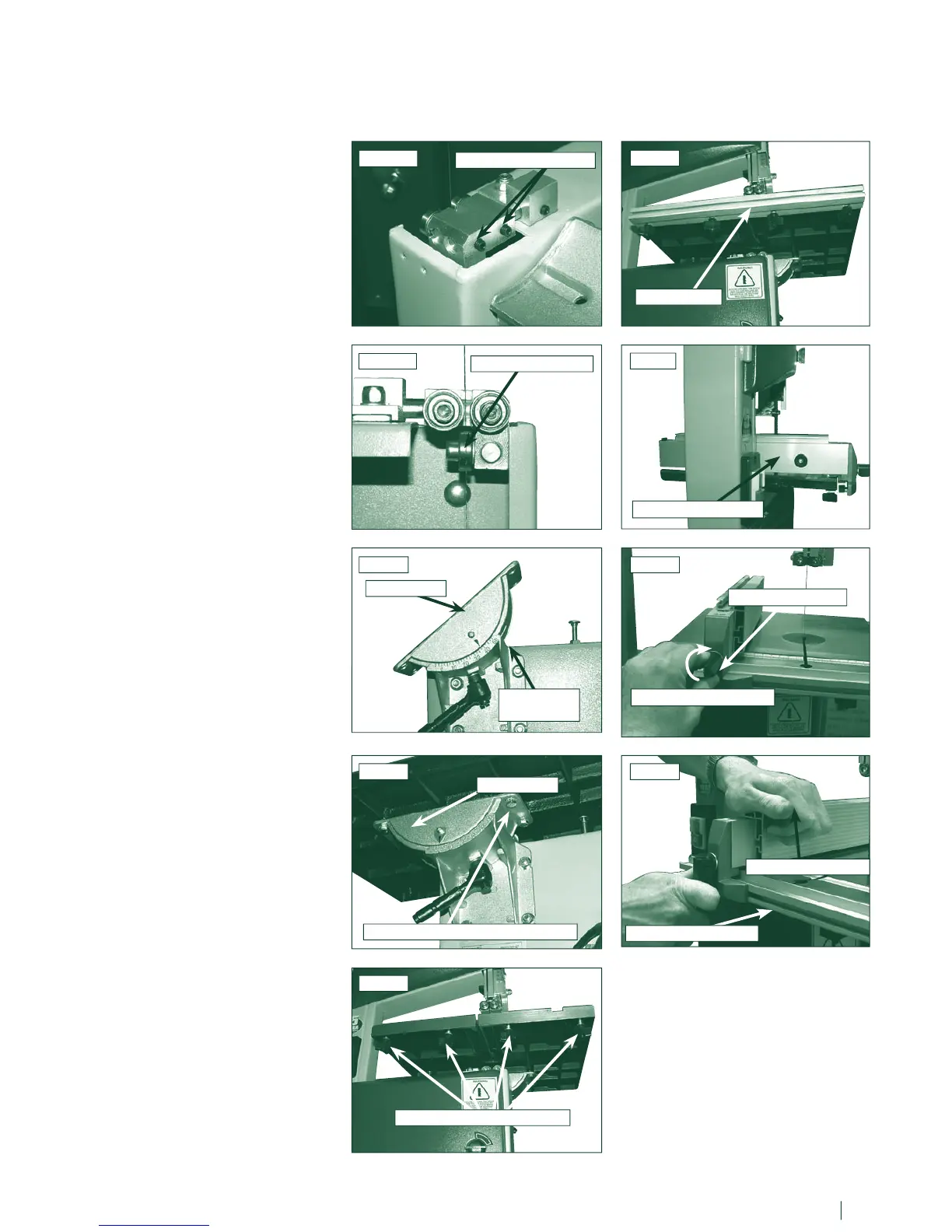

4.3 Fitting the rip fence

Slide the rip fence assembly onto the

fence rail and along the back of the table

Fig.4.6.

Pull down the locking lever to secure

the position, if the locking lever does

not lock the fence it can be adjusted by

rotating it clockwise this will enable the

fence to be locked securely

Fig.4.7.

Do not over tighten as this can damage

the cam. Tighten just enough to keep the

fence stable and secure.

Adjust this until you are happy with the

setting.

Tip

When locking the rip fence it is

advisable in place downward pressure

on the top of the fence

with one hand.

This ensures that the fence registers

correctly on the bottom flat of the

fence rail Fig.4.8.

Fig.4.4

Fig.4.5

Fig.4.6

Fig.4.7

Fig.4.8

Fig.4.1A

Fig.4.2

TRUNNION

TWO GRUB SCREWS

FENCE RAIL

STAR KNOBS & WASHERS

FENCE ASSEMBLY

LOCKING LEVER

APPLY PRESSURE

TRUNNION

CARRIER

BOTTOM FLAT RAIL

ROTATE TO TIGHTEN

Loading...

Loading...