11. Maintenance

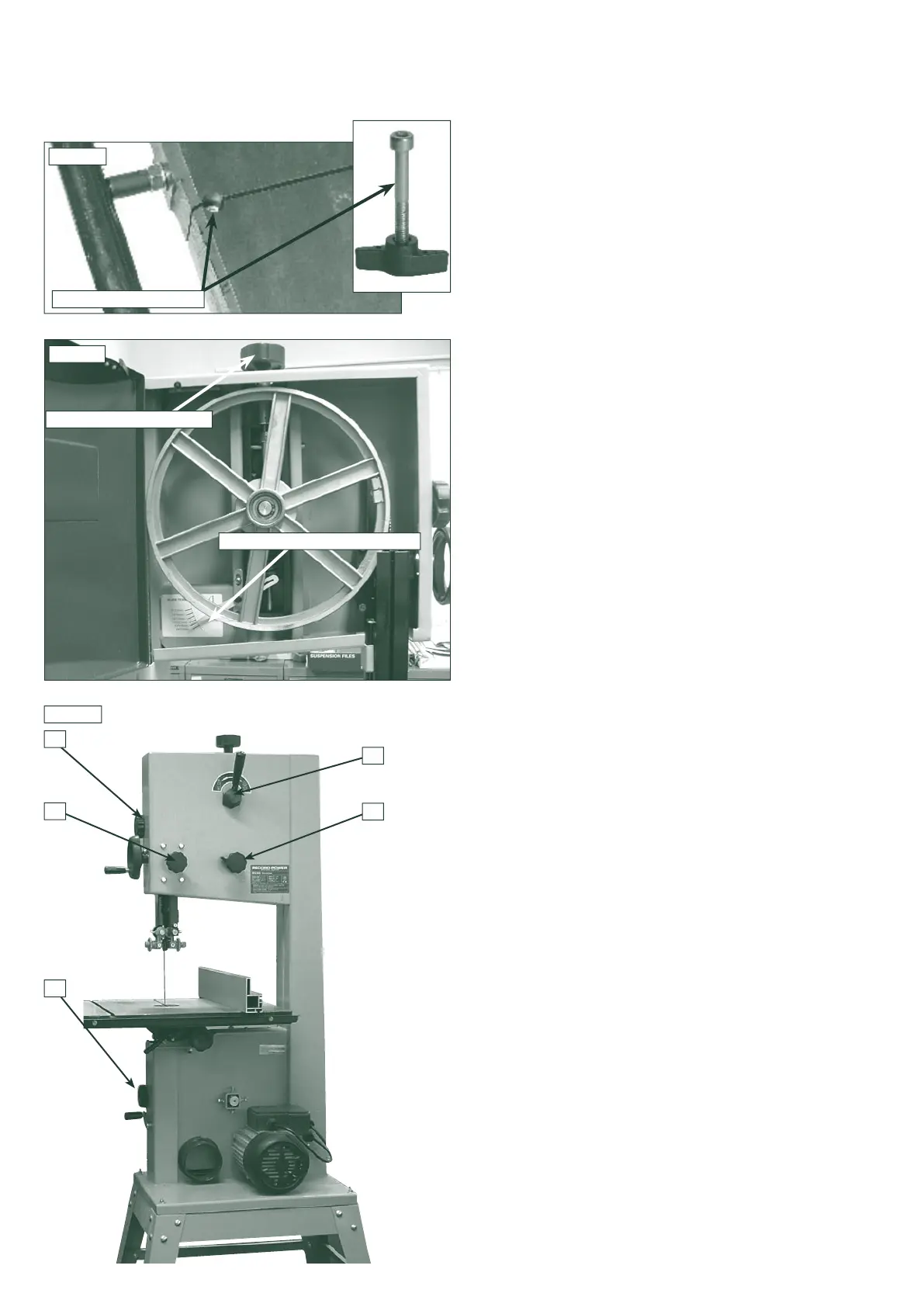

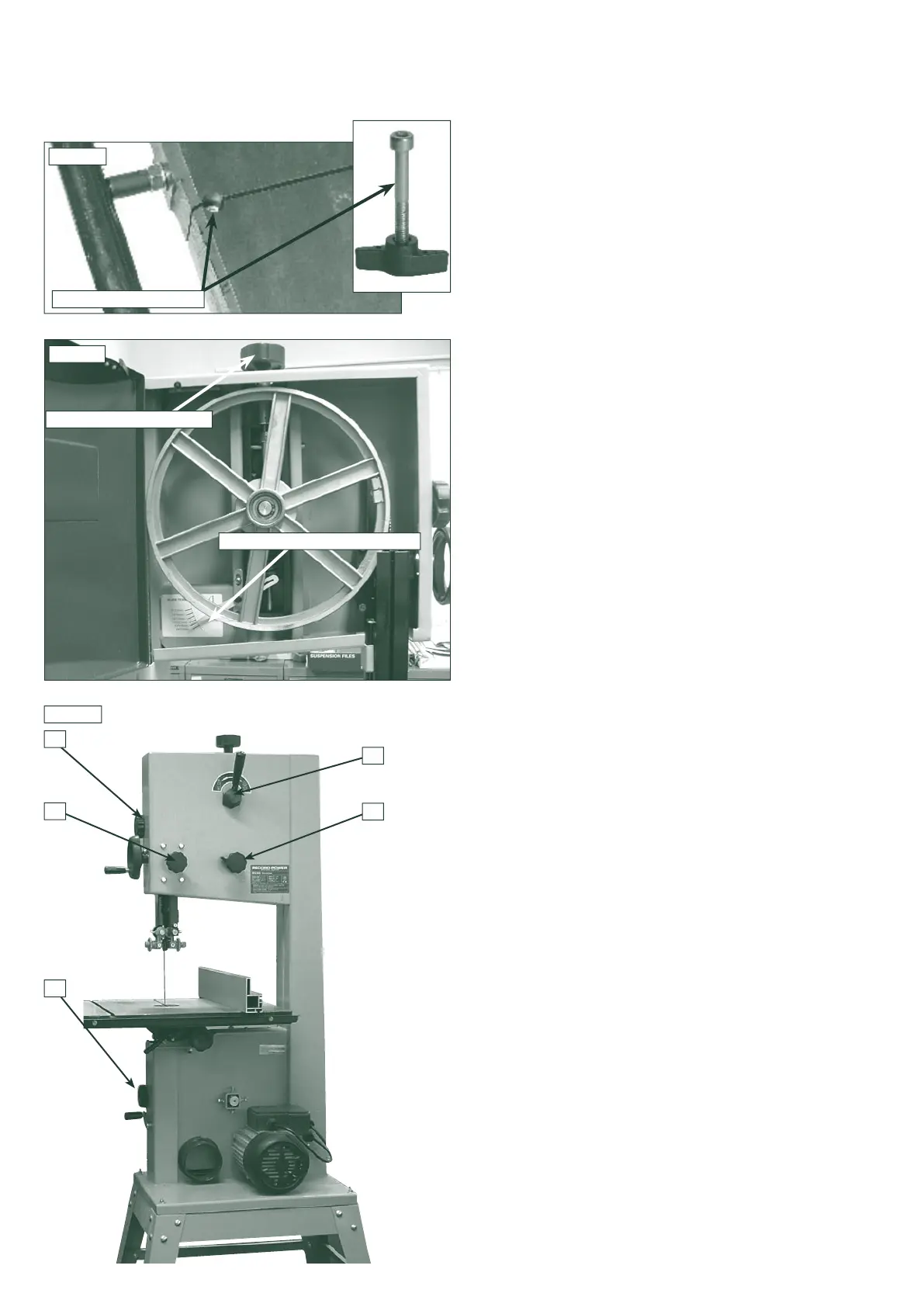

BLADE TENSION INDICATOR

BLADE TENSION KNOB

17

15

16

14

14

11.1 Replacing the bandsaw blade

HAZARD!

Take great care when unpacking the bandsaw blade

as they are usually folded and can spring out very suddenly with

great force.

TIP: If the new blade being fitted is a different width to the one

being removed, it is advisable to move back and slacken off all

blade guides before fitting the new blade as this will make fitting

easier. Whenever a different size blade is fitted the blade guides

will always need re-setting.

1.

Isolate the machine from the power supply.

2. Open the top and bottom bandwheel doors by turning the

star handle

Fig 11.3 (14).

4.

Remove the Hex socket screw, bushing and wing nut

fitted to the front of the table

Fig 11.1

.

5.

Move the lever clockwise to

release the blade tension

. Fig

11.3 (17)

.

6. Remove the bandsaw blade by feeding it through the

slot in the table, upper blade guides & guard and slot in

the spine of the machine taking care not to cut yourself,

wear gloves if necessary.

7a. If the new blade being fitted is a different width to the

one being removed, before the new blade is placed

around the bandwheels:

• Re-apply the cam handle moving the bandwheel

upwards. Now adjust the tension wheel to suit the new

blade size.

• Once the tension indicator is showing the correct

reading for the new blade release the cam handle

and place the new blade on the bandwheels.

• When fitting the new blade ensure the blade teeth are

pointing downwards and towards you at the position

where the blade passes through the table.

•

Ensuring that the blade is fully in place on bandwheel,

re-apply tension using the cam handle.

• Fine adjust the blade tension further if required using the

blade tension wheel.

7b. If the new blade width is the same as the blade being

removed:

• Fit the new blade ensuring the blade teeth are pointing

downwards and towards you at the position where the

blade passes through the table.

• Ensuring that the blade is fully in place on bandwheel.

Simply re-apply tension using the cam handle lever.

• Fine adjust the blade tension further if required using the

blade tension wheel.

8.

Check the blade tracking on the newly fitted blade by

turning the upper wheel by hand. The blade should run

as close to the centre of the bandwheel as possible.

On 1/4", 3/8" and 1/2" blades it may be necessary to run

the blade to rear of the bandwheel

(see section 6.2.)

9. If required adjust the tracking using tracking knob

(15)

and

lock knob to the rear of the upper bandwheel housing.

When the tracking is correct lock the settin

g (see section

6.2)

.

10.

Re-set the blade guides

(see sections 6.3 & 6.4)

11. Close and lock both the bandwheel doors before re

connecting the power supply.

The blade tension indicator is a guide only and may need

re-calibrating periodically. For further information on blade

tensioning

see section 6.1

.

CAUTION!

Before carrying out any adjustments or maintenance

ensure that the machine is isolated and disconnected

from the electricity supply.

Fig.11.1

Fig.11.2

HEX SOCKET SCREW

Fig.11.3

Loading...

Loading...