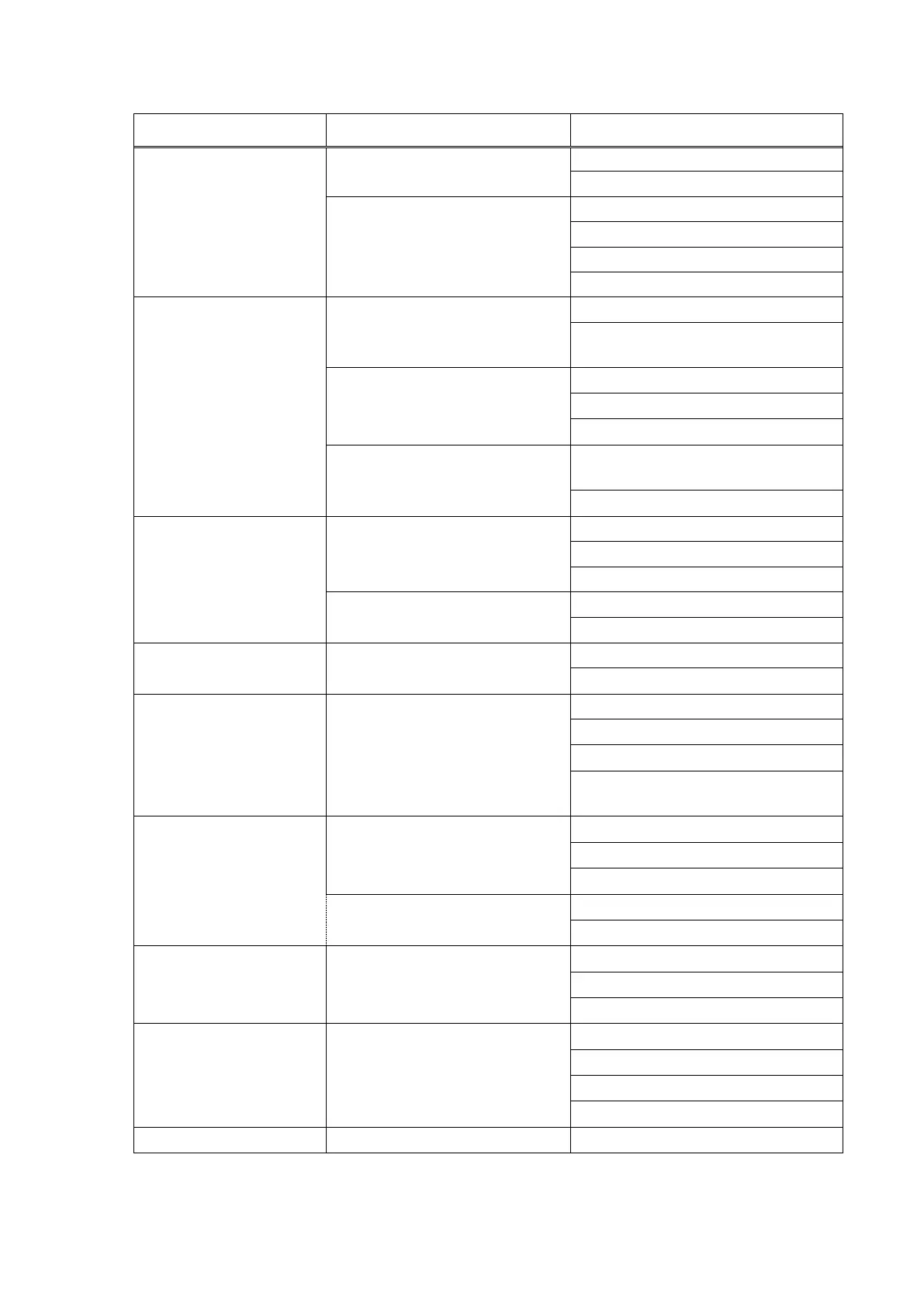

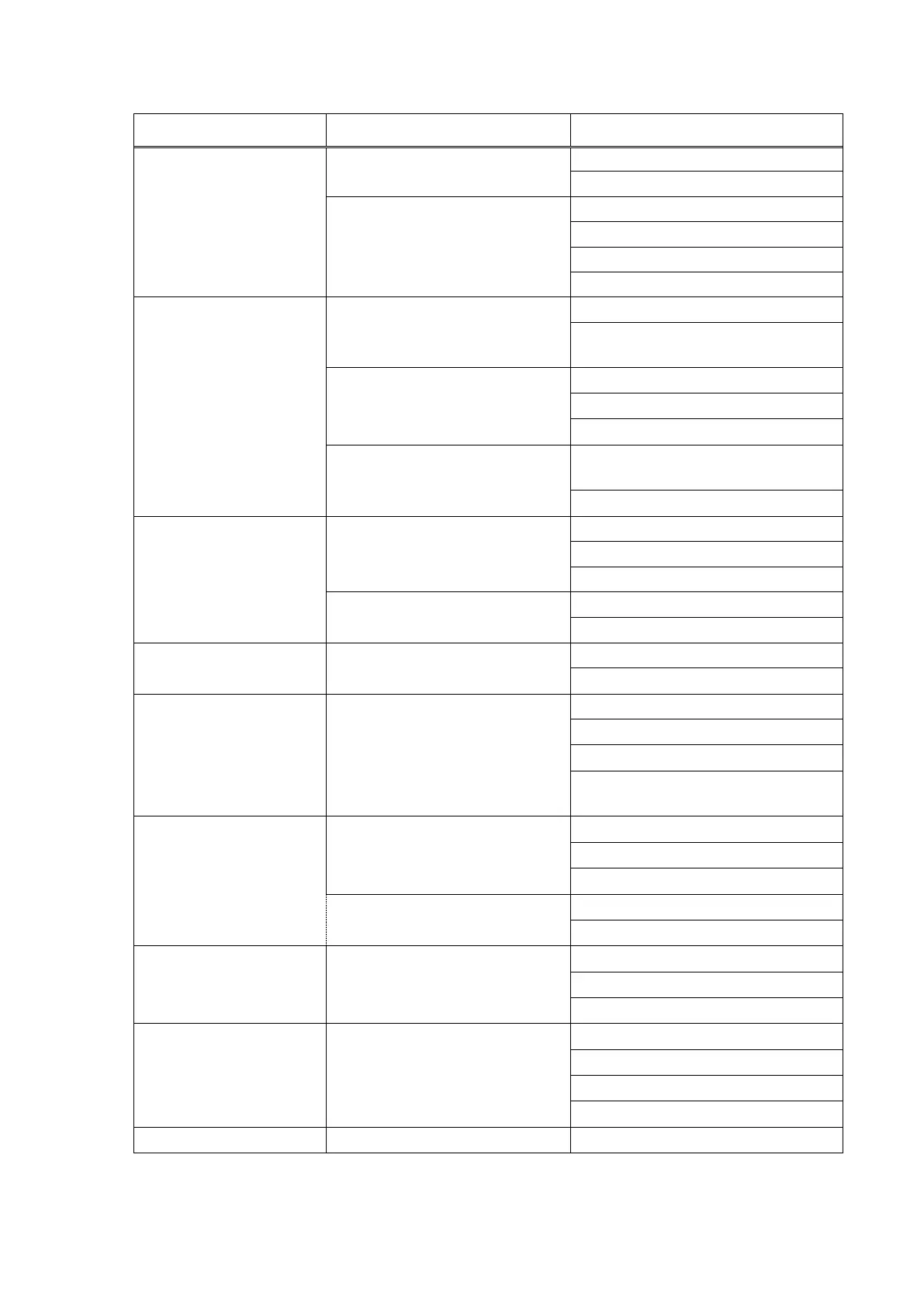

12.0 PROBLEM ANALYSIS

Crankshaft turns irregularly.

Machine not at 90 degrees.

Angles pivot points PTO differ.

Pivot points PTO not in line.

Use thinner/shorter tines.

In case of draught, irrigate first.

Change tine, use shorter ones.

Use solid tines before hollow tines

to break open the soil.

Use thinner/ shorter tines.

In case of draught, irrigate first.

First use solid tines to break open

the soil.

Front roller is not stable

PTO angles are too large.

PTO angles are dissimilar.

Machine not at 90 degrees.

Bearing retainers worn out.

Tines hit the ground when

reversing the machine.

Change tine angle setting.

Grind part of the tines flat.

Fix the vibration, see vibration.

Crankshaft bearing worn out.

Wrong reassembly after repair.

Remove, clean, use Loctite.

Loading...

Loading...