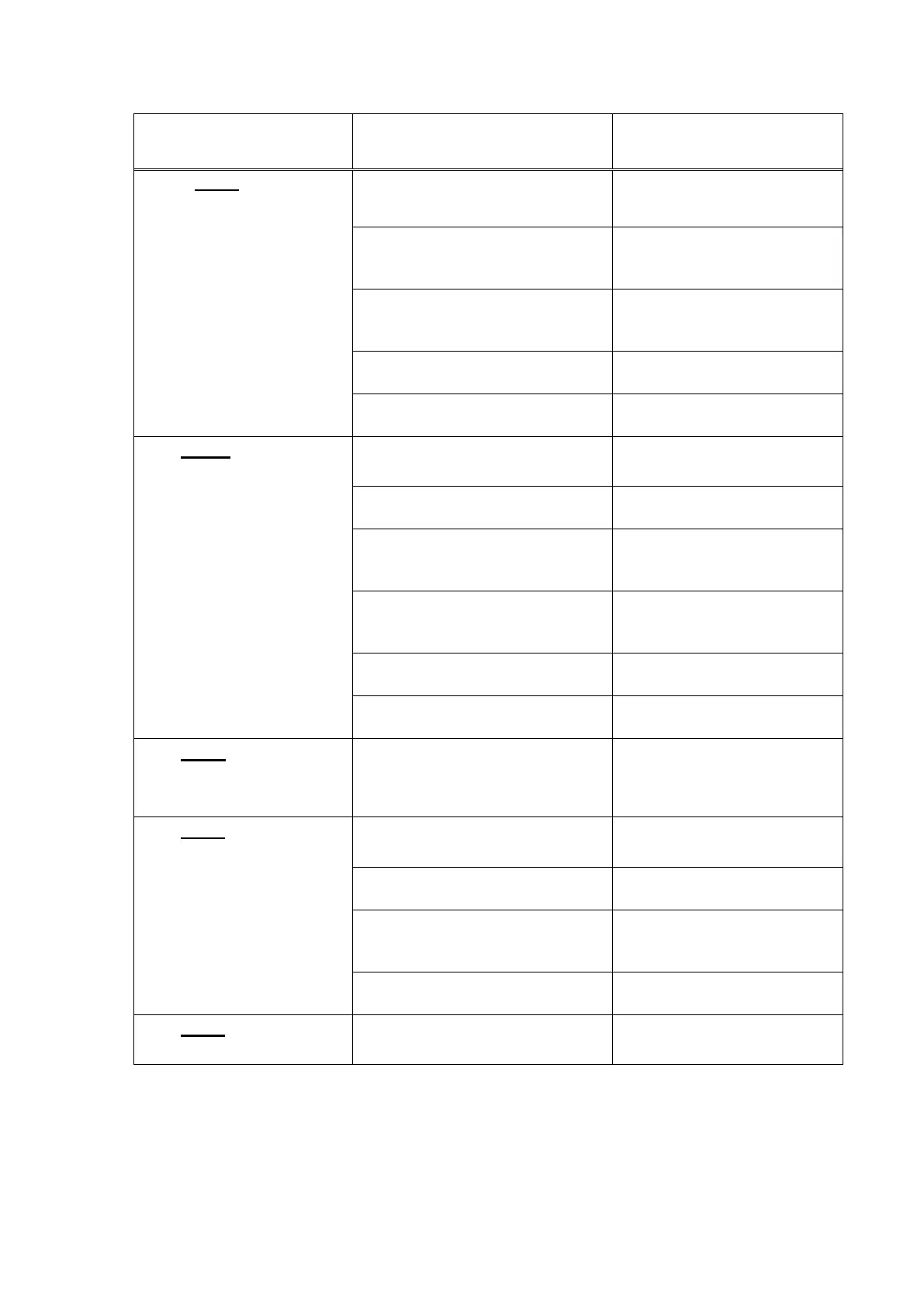

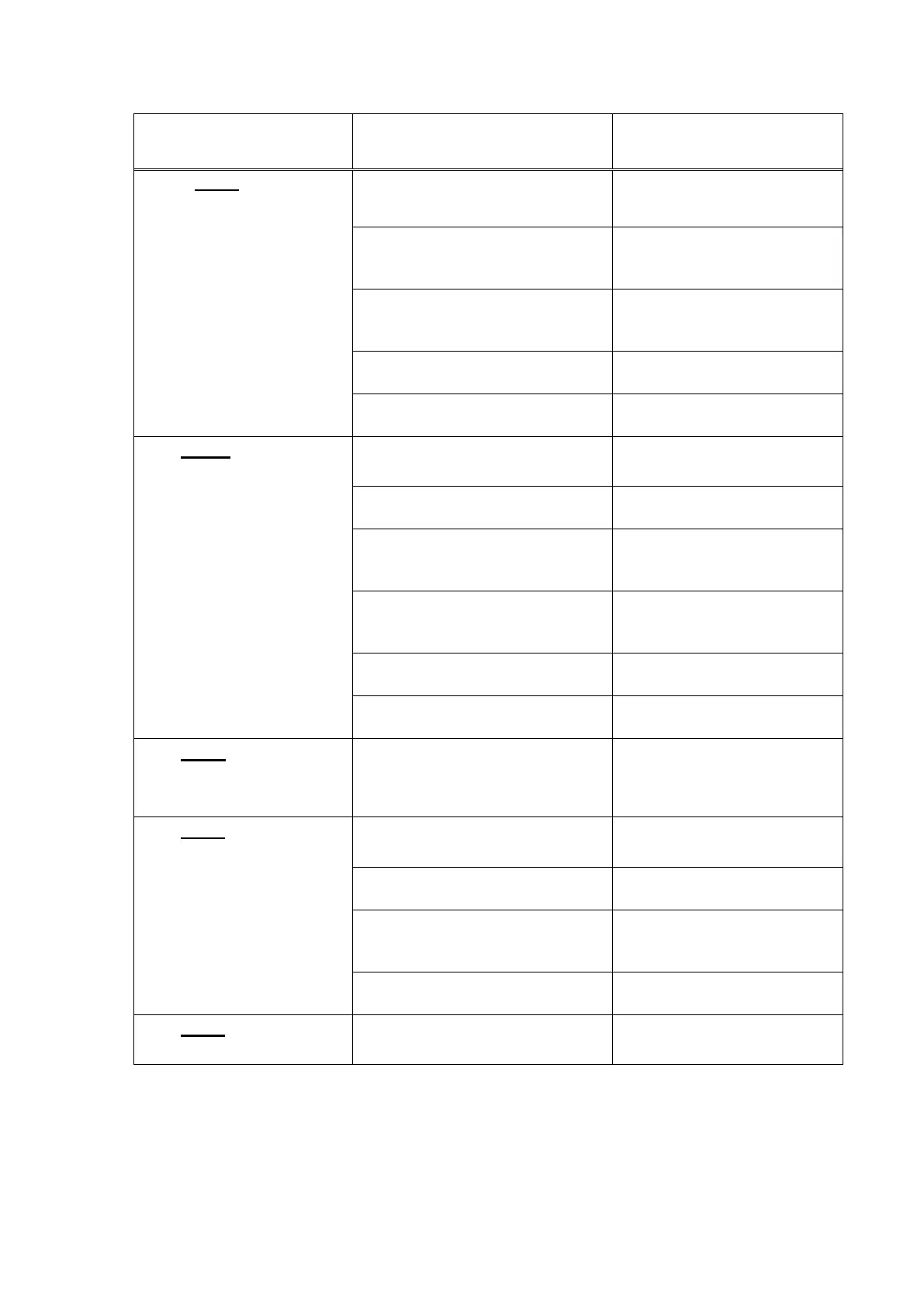

13.0 MAINTENANCE

Check point /

Lubrication point

Check for loose bolts / nuts.

Tighten the loose bolts/nuts

with the correct torque.

Couple the machine to a tractor

and let the machine run for 5

Look and listen for strange

movements/noises.

Check the oil level in the gear

casings.

80W90 - 0.9 LITER.

Presence and legibility of the

safety stickers. (Fig.7)

Replace these if

absent/damaged.

Loose parts near the PTO.

Secure the parts so they do

not come close to the PTO.

After initial 20 operating

hours

Lubricate PTO, roller bearings

Use EP 2 lubricating grease.

Check for loose bolts / nuts.

Tighten the loose bolts/nuts

with the correct torque.

Couple the machine to a tractor

and let the machine run for 5

Look and listen for strange

movements/noises.

Check the oil level in the gear

casings; this has to reach to the

middle of the level indicator.

Check the gearbox for oil

leakage.

Replace seals / sealant

paste.

Loose parts near the PTO.

Secure the parts so they do

not come close to the PTO.

After initial 50 operating

hours

(new or repaired)

Change the oil in the gear

casing.

hours

Lubricate PTO, roller bearings

Use EP 2 lubricating grease.

Check for loose bolts / nuts.

Tighten the loose bolts/nuts

with the correct moment.

Couple the machine to a tractor

and let the machine run for 5

Look and listen for strange

movements/noises.

Check the gearbox for oil

leakage.

Replace seals / sealant

paste.

After every 500 operating

hours

Change the oil in the gear

casing.

Loading...

Loading...