Servitec 35-95 with

— 18.12.2019 - Rev. A

English —

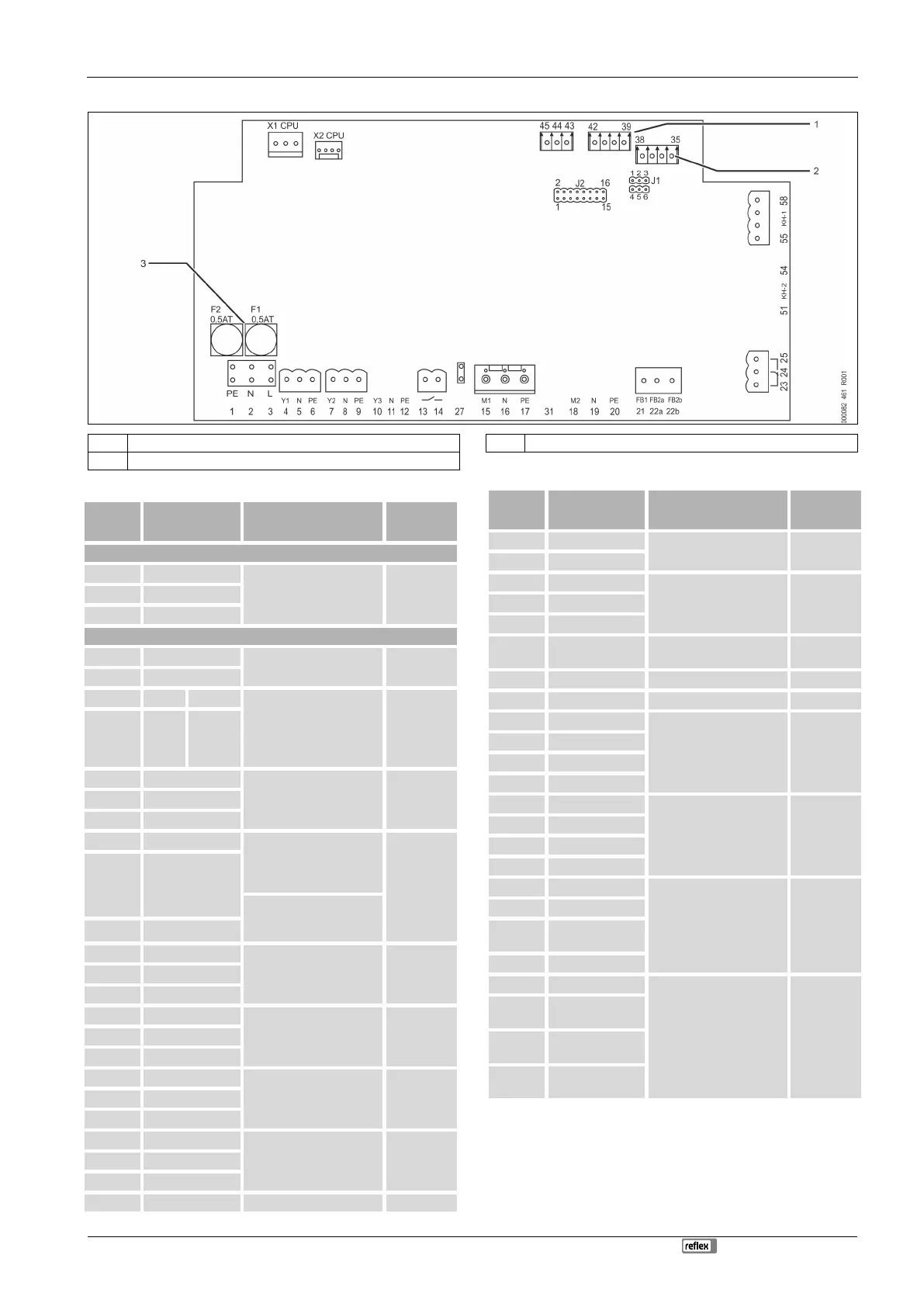

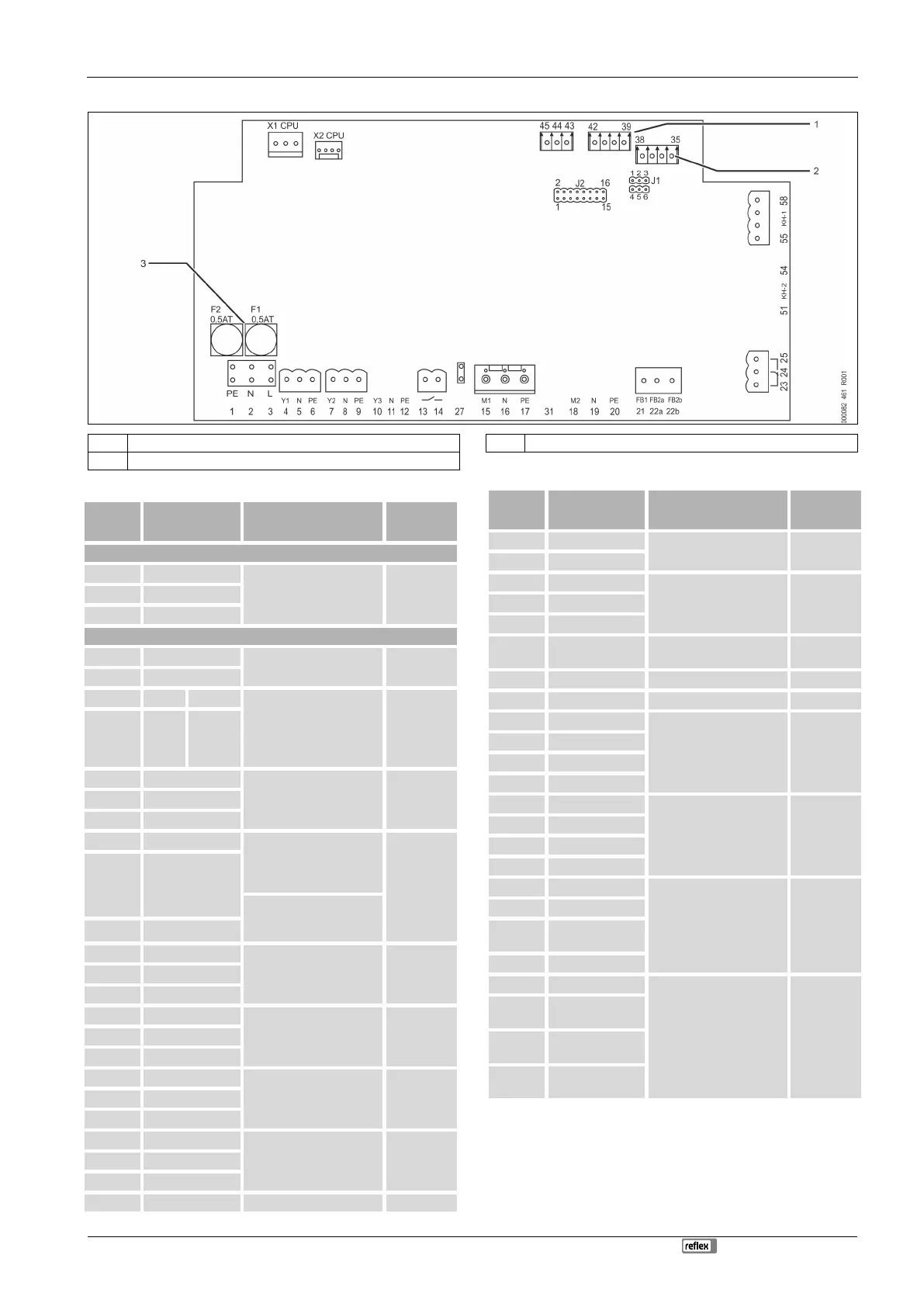

6.5.1 Terminal plan, connection component

1 Pressure 3 Fuses

2 Conductivity

Supply

X0/1 L

Supply 230 V, maximum

16 A.

• Servitec 35-95

User supplied X0/2 N

X0/3 PE

Circuit board

13 NO

Dry-running protection

message (floating).

User, optional

14 COM

22a FB2a COM External make-up request.

– With Levelcontrol

setting.

Input 230 V signal via

L+N.

User, optional

22b FB2b NO

23 NC

Group message (floating). User, optional 24 COM

25 NO

43 +24 V

• E1, digital input from

the contact water

meter.

Terminal 43+44.

E1, user

option

E2, factory

44 E1

• E2, insufficient water

switch.

Terminal 43+45.

45 E2

1 PE

Voltage supply. Factory 2 N

3 L

4 Y1

WV make-up valve Pre-wired 5 N

6 PE

7 Y2

CD degassing control valve Pre-wired 8 N

9 PE

10 Y3

--- --- 11 N

12 PE

15 M1 "PU" pump Pre-wired

16 N

17 PE

18 M2

--- --- 19 N

20 PE

21 FB1 Voltage monitoring PU

pump

Pre-wired

27 M1 PU pump supply Pre-wired

31 M2 --- ---

35 +18V

Analogue input conductivity

Lf.

User, optional

36 GND

37 AE

38 Shielding

39 + 18 V (blue)

Analogue input "PIS"

pressure measuring.

– For pressure indication

and make-up with the

"Magcontrol" setting.

Pre-wired

40 GND

41 AE (brown)

42 Shielding (black)

51 GND

--- ---

52 +24 V (supply)

53 0–10V (correcting

variable)

54 0–10V (feedback)

55 GND (black)

Control ball valve"PV"

– For regulating the

hydraulic adjustment

of degassing.

Pre-wired

56

+24 V (supply)

(red)

57

0–10V (correcting

variable) (white)

58

0–10V (feedback)

(orange)

Loading...

Loading...