Servitec 35-95 with

— 18.12.2019 - Rev. A

English —

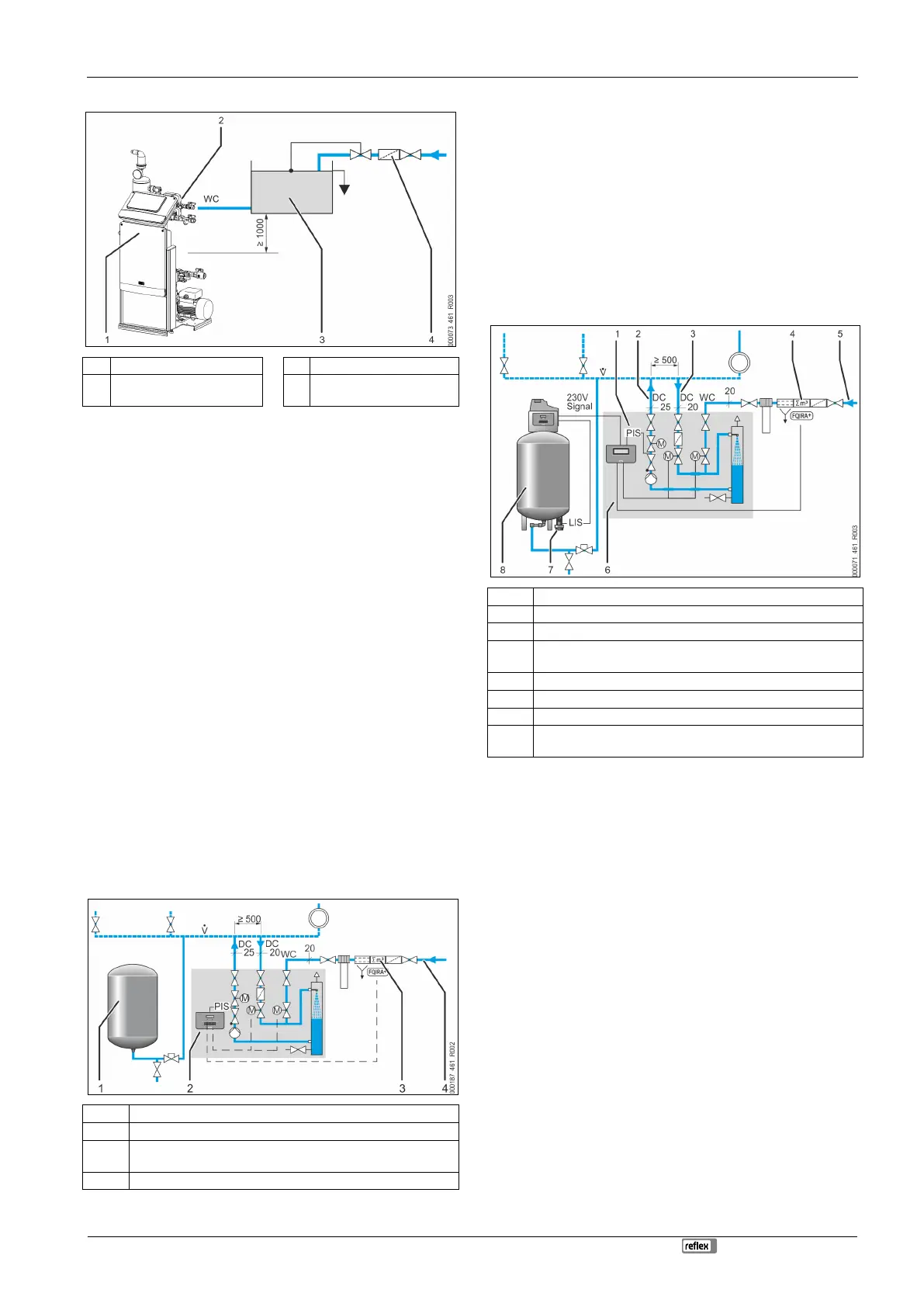

6.3.3.2 Make-up line

1 Servitec 3 "BT" system separator vessel

2

"WV" 2-way motorized ball

valve

4 "ST" dirt trap

For a water make-up via a "BT" mains disconnect receptacle, its bottom edge

must be at least 1000 mm above the "PU" degassing pump.

Various Reflex make-up variants, see chapter 4.6 "Optional equipment and

accessories" on page 6 .

If you do not connect the automatic water make-up, you must close the

connection of the "WC" make-up line with a R ½ " blanking plug and start up the

system in "Levelcontrol" mode.

For external water make-up, note the following conditions:

• Install at least one "ST" dirt trap with a mesh size ≤ 0.25 mm close

upstream to the "WV" 2-way motorized ball valve or use our Fillset.

Note!

When using an external system make

-up, ensure that no Servitec fault

occurs as a result of different operating parameters.

Note!

Use a pressure reducer in the "WC" make

-up line if the idle pressure

6.4 Switching and make-up variants

Select the make-up variant in the Customer menu of the device controller, see

chapter 9.1.1 "Customer menu" on page 18 .

Choose from one of the following make-up variants in the Customer menu:

• Pressure-dependent "Magcontrol" make-up.

– In a facility system with diaphragm expansion tank.

• Level-dependent "Levelcontrol" make-up.

– In a facility system with pressure maintaining station.

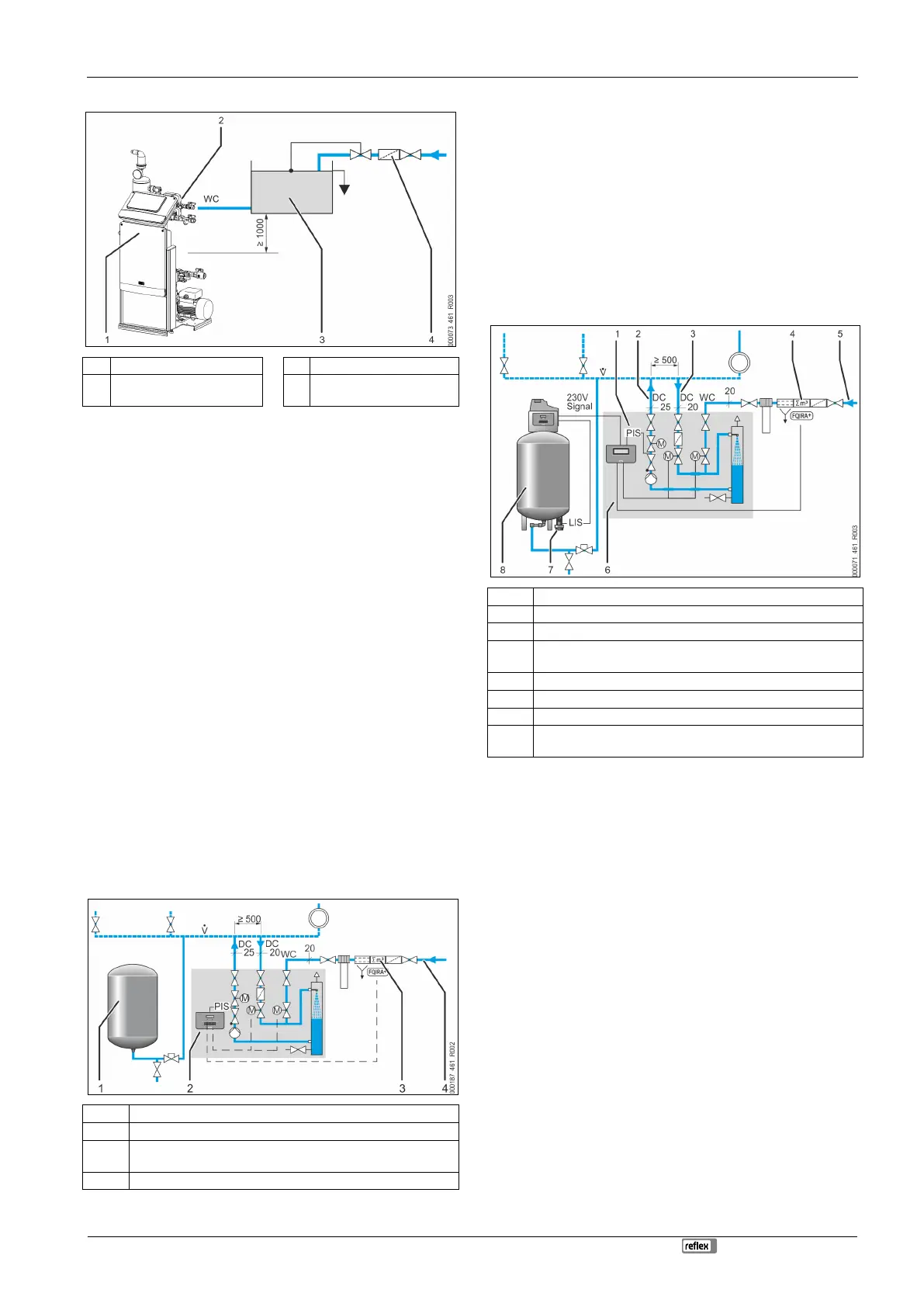

6.4.1 Pressure-dependent "Magcontrol" make-up mode

Example representation of a multi-tank system with hydraulic switching point

and a "MAG" diaphragm-type expansion vessel.

1 "MAG" expansion vessel

2 Servitec

3

Optional equipment and accessories see chapter 4.6 "Optional

equipment and accessories" on page 6

4 "WC" make-up line

The "Magcontrol" operating mode is set in the Customer menu of the Servitec

controller. This operating mode is used for plant systems with a diaphragm-type

expansion vessel. The make-up action depends on the pressure. The required

"PIS" pressure sensor is integrated in the Servitec. The "DC" degassing lines are

connected close to the diaphragm-type expansion vessel. In this way precise

pressure monitoring is enable for demand-matched make-up as.

Note!

Connect the degassing lines on the return side of the system upstream

of the hydraulic switching point. In this manner the permissible

temperature range of 0° - 90°C is adhered to.

6.4.2 Level dependent "Levelcontrol" make-up mode

Typical representation of Servitec 35 - 95 with motorized ball valves in a facility

system.

1 "PIS" pressure transducer

2 "DC" degassing line (degassed water)

3 "DC" degassing line (gas-rich water)

4 Optional equipment and accessories see chapter 4.6 "Optional

equipment and accessories" on page 6

5 "WC" make-up line

6 Servitec

7 "LIS" pressure pick-up

8 Pressure-maintaining station (compressor-controlled) with expansion

vessel

The "Levelcontrol" operating mode is set in the Customer menu of the device

controller. This operating mode is used for facility systems with pressure-

maintaining stations. The make-up with water depends on the filling level in the

expansion vessel of the pressure-maintaining station. The "LIS" pressure

transducer determines the filling level and sends this value to the controller of

the pressure maintenance station. The controller sends a 230 V signal to the

device controller when the filling level in the expansion vessel has fallen below

the set value.

Make-up with water is realised by regulating the motorized ball valve in the

"WC" make-up line. The device controller regulates the motor actuator of the

motorized ball valves. This ensures a controlled make-up with water and

monitoring of the make-up time and cycles.

Loading...

Loading...