— English Servitec 35-95 with

— 18.12.2019 - Rev. A

Note!

During installation, pay attention to the operability of the valves and the

inlet options for the connecting lines.

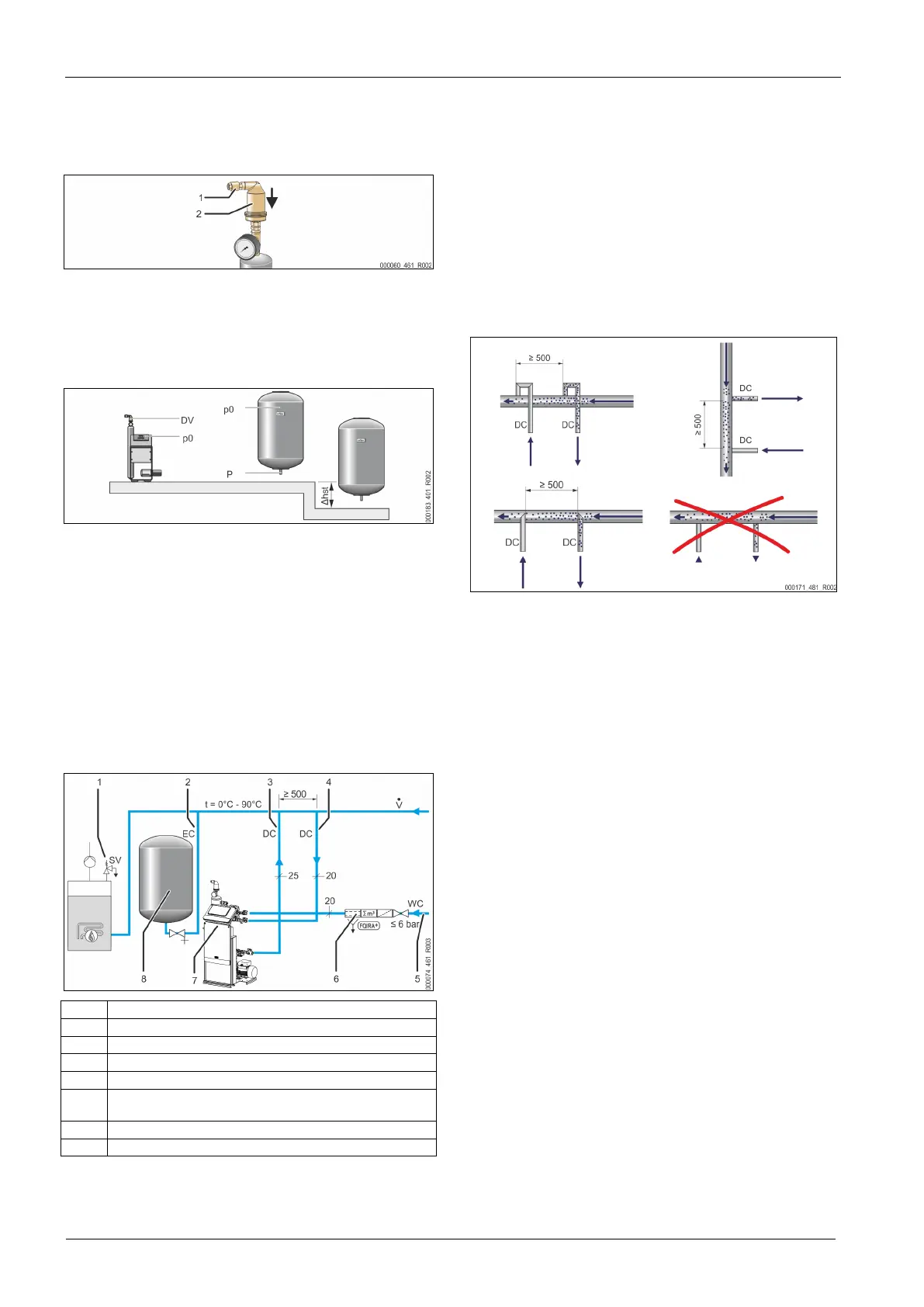

6.3.1 Fitting the add-on components

Install the "DV" degassing valve (2) with the check valve (1) on the "VT" vacuum

spray tube. Check all screw fittings of the Servitec for proper seating.

6.3.2 Installation location

The Servitec is installed on the floor. Select the attachment means according to

the floor properties and the weight of the Servitec.

Note!

Consider a potential difference in head "h

st

" between the expansion

vessel and the device when calculating the "P

0

" minimum operating

6.3.3 Hydraulic connection

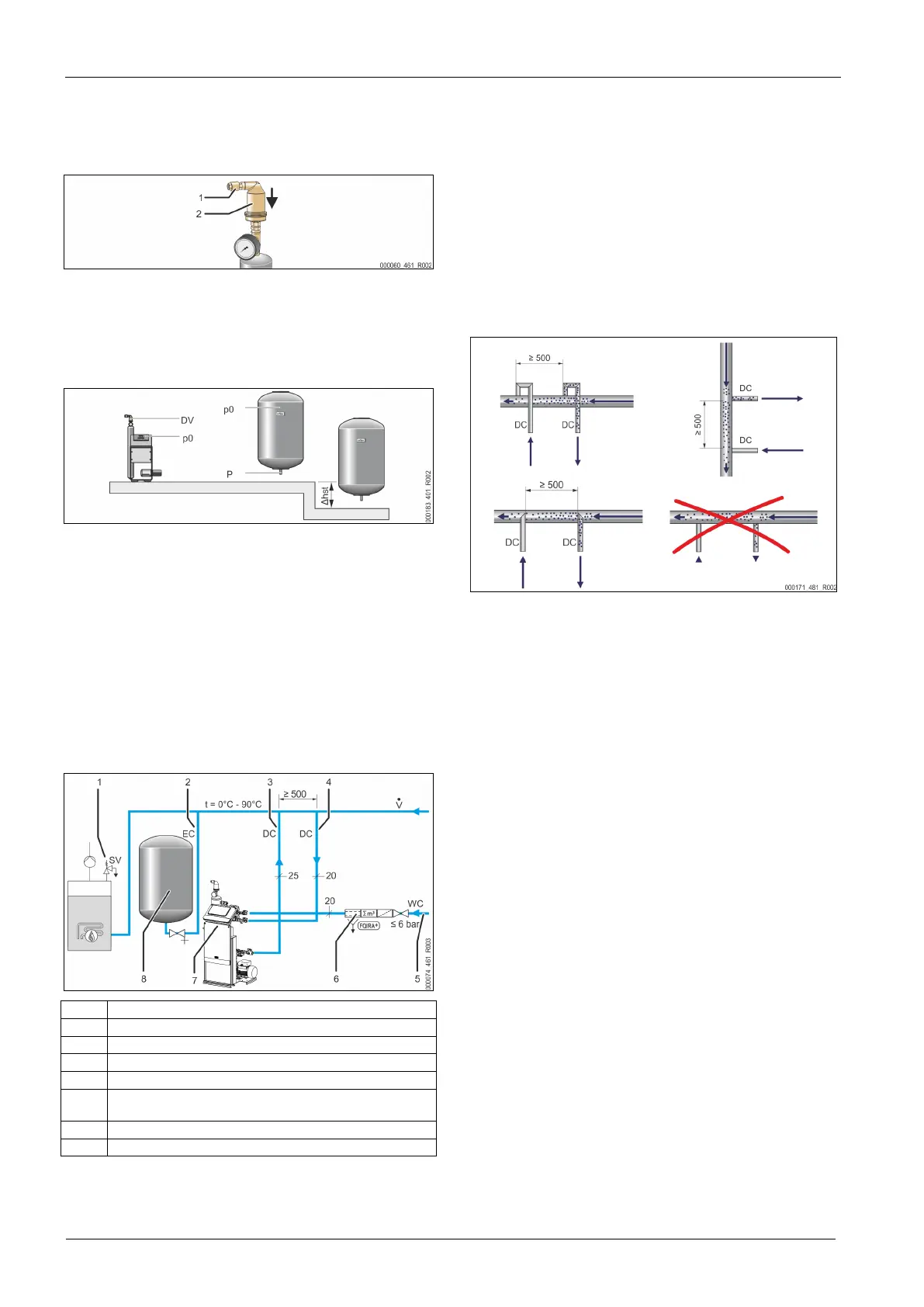

6.3.3.1 Degassing line to the system

The device requires two "DC" degassing lines to the system. One degassing line is

intended for gas-rich water from the system, and the other one serves to return

the degassed water to the system. Shut-off devices for both degassing lines have

been pre-installed at the device. The connections of the degassing lines must be

made within the main flow volume of the facility system.

Device installation in a heating system – Pressure maintenance with expansion

vessel

1 "SV" safety valve

2 "EC" expansion line

3 "DC" degassing line (degassed water)

4 "DC" degassing lines (gas-rich water)

5 "WC" make-up line

6

Optional equipment and accessories see chapter 4.6 "Optional

equipment and accessories" on page 6 .

7 Servitec

8 Expansion vessel

The degassing lines into the system are to be installed near the connection point

of the "EC" expansion line. This ensures stable pressure conditions.

If you operate the device with pressure-dependent water make-up, you must

install the system near the diaphragm-type expansion vessel. This ensures that

the pressure in the diaphragm-type expansion vessel is monitored. In this case,

select the "Magcontrol" operating mode in the controller.

Note!

Ensure the integration in the "V" main flow volume when using

switching variants with hydraulic switching points and return

admixtures.

For switching and make-up variants, see chapter 6.4 "Switching

and make-up variants" on page 9 .

Installation detail of the "DC" degassing line

Connect the "DC" degassing lines as shown below.

• Ensure that particulate dirt cannot enter and thus create an overload of the

Servitec's "ST" dirt trap.

• Connect the degassing line for gas-rich water upstream of the degassing

line for degassed water in system direction of flow.

• The water temperature must be in the range > 0 °C – 90 °C. The return line

side should be preferred for heating systems. This ensures the permissible

temperature range for degassing.

Loading...

Loading...