Servitec 35-95 with

— 18.12.2019 - Rev. A

English —

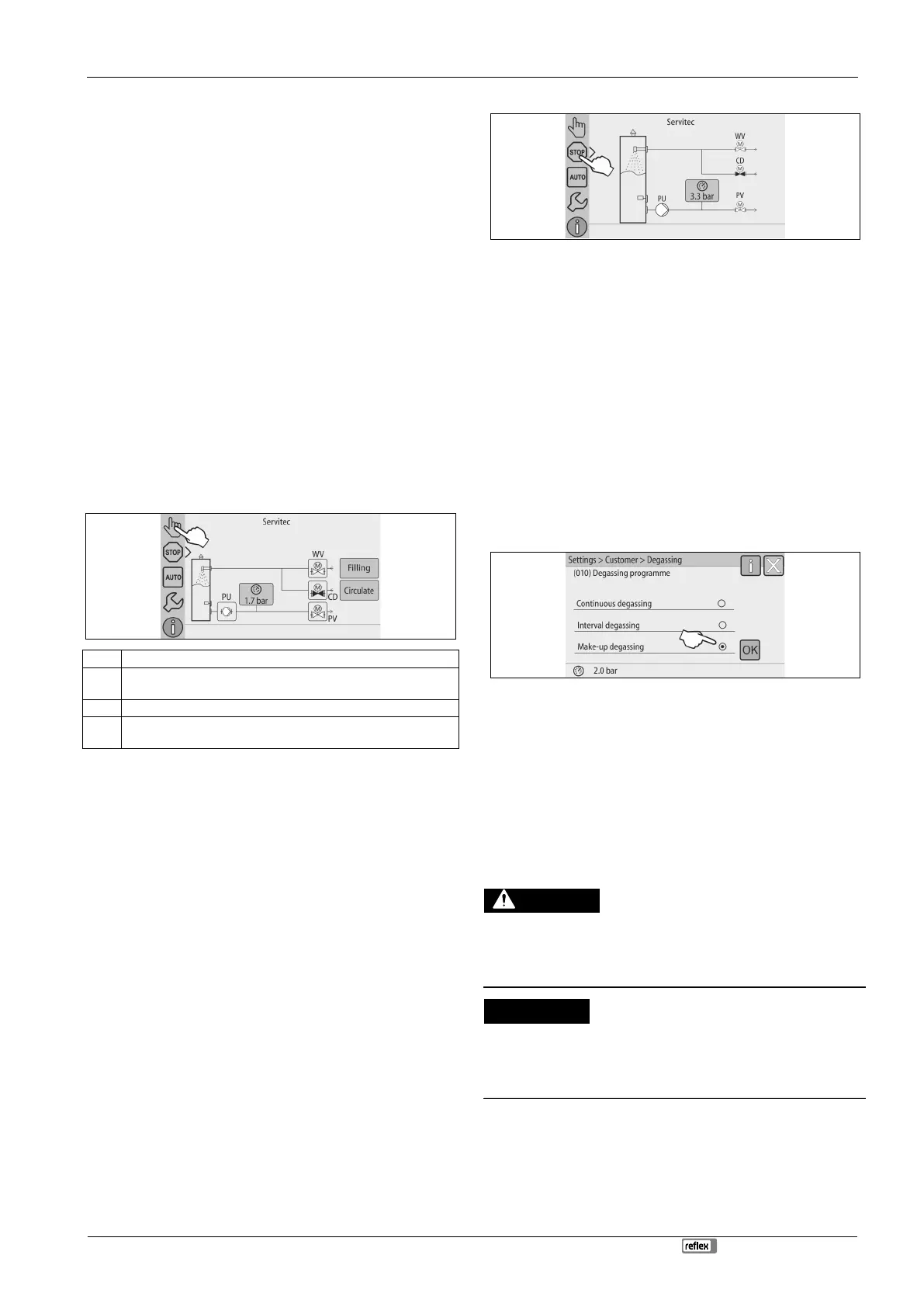

Select a degassing programme for Automatic mode. The Customer menu

provides three different degassing programmes for selection, see chapter 9.1.4

"Degassing programmes – overview" on page 19 .

• Continuous degassing.

• Interval degassing.

• Degassing the make-up water.

For selecting the degassing programmes, see chapter 9.1.5 "Setting degassing

programmes" on page 20 .

The controller displays the selected degassing programme in the message line.

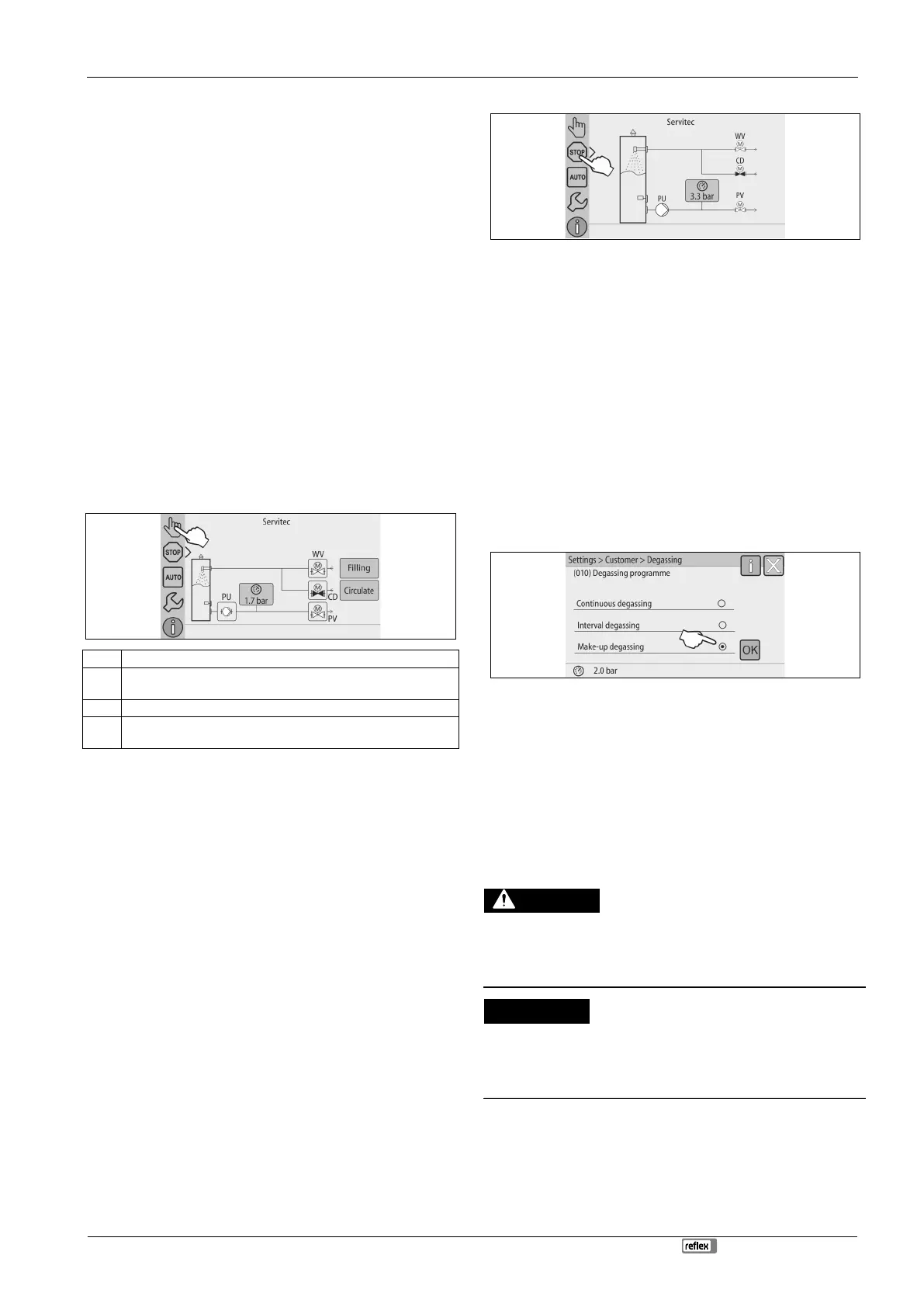

8.1.2 Manual mode

Manual mode enables you to select the following For performing a test run and

service tasks:

• 2-way motorized ball valve for degassing the system and the make-up

water "WV" and "CD"

– Manual actuator for opening or closing.

• Pump.

– For switching the pump on and off.

• 2-way motorized ball valve (PV) in the line downstream of the pump

– Manual actuator for opening or closing.

• Filling.

– Make-up degassing is activated.

– For filling facility systems with pressure-dependent water make-up

"Magcontrol".

• Circulation.

– Activates continuous degassing of the facility water without time

limit.

– For vacuum test during commissioning.

WV 2-way motorized ball valve in the make-up line

CD 2-way motorized ball valve in the degassing line from the system to the

Servitec

PU Pump

PV 2-way motorized ball valve in the degassing line from the Servitec to the

system

You have the option to simultaneously switch multiple functions and to test

them in parallel. Switch the function on and off by touching the corresponding

button.

• The button is highlighted green: The function is switched off.

• Press the desired button.

• The button is highlighted blue: The function is switched on.

Proceed as follows:

1. Press "Manual mode".

2. Select the desired function:

• 2x 2-way motorized ball valve in the make-up line (WV) and the

degassing line from the system to the Servitec (CD)

• Pump (PU)

• 2-way motorized ball valve in the the degassing line (PV)

• Fill (PV opens if PU is active)

• Circulate

3. Press "AUTO" to deactivate Manual mode.

• Automatic mode is activated.

Note!

Manual operations cannot be performed if safety

-relevant parameters

Switching is blocked if safety-relevant settings would not be

8.1.3 Stop mode

Except for the display of information, the device is non-functional in Stop mode.

Function monitoring is stopped.

The following functions are deactivated:

• The pump is switched off.

• The 2-way motorized ball valve in the degassing line from the Servitec to

the system (PV) is closed.

• The 2-way motorized ball valve in the make-up line (WV) is closed.

• The 2-way motorized ball valve in the degassing line from System to the

Servitec (CD) is closed.

To start Stop mode operation, proceed as follows:

• Touch "STOP".

Note!

The system returns an

alarm if the Stop mode is activated for more than

If "Volt free contact?" in the Customer menu is set to "Yes", the

system outputs the alarm to the group alarm contact.

8.1.4 Summer operation

If you have placed the facility system circulating pumps out of service during the

summer, no degassing of the plan system water occurs.

Proceed as follows:

• In this case, use the Customer menu to select the "Make-up degassing"

degassing programme.

• After Summer, select the "Interval degassing" degassing programme in the

Customer menu or "Continuous degassing", if required.

Note!

For a detailed description of the selection of degassing programmes, see

chapter 9.1.5 "Setting degassing programmes" on page 20 .

8.2 Restarting

Risk of injury due to pump start-up

Hand injuries may occur when the pump starts up if you turn the pump motor at

the impeller using a screwdriver.

• Switch the pump to a zero-volts state before turning the pump at the fan

wheel with a screwdriver.

Device damage due to pump start-up

Pump damage may occur when the pump starts up if you turn the pump motor

at the impeller using a screwdriver.

• Switch the pump to a zero-volts state before turning the pump at the fan

wheel with a screwdriver.

After an extended device standstill time (the device is disconnected from the

power or in Stop mode), the pump may jam. For this reason, use a screwdriver to

rotate the pump at the fan wheel of the pump motor before restarting.

Note!

In device automatic mode, jamming of the pump is prevented b

y a

forced start (after 24 hours).

Loading...

Loading...