Variomat Touch — 09.2020 - Rev. A

7.5.4 RS-485 interface

Use the S1 and S2 RS-485 interfaces to retrieve all controller data and to enable

the communication with control centres or other devices.

• S1 interface

– A maximum 10 devices can be used in a master-slave linked circuit

via the this interface.

• S2 interface

– "PIS" pressure and "LIS" level.

– Operating modes of the "PU" pumps.

– Operating states of the motorised ball valve/solenoid valve.

– Values of the "FQIRA +" contact water meter.

– All messages.

– All entries in the fault memory.

The following bus modules form part of the optional accessories available for

interface communication.

Note!

If required, please contact the Reflex Customer Service for the protocol

of the RS-485 interface, details of the connections and information about

the accessories offered.

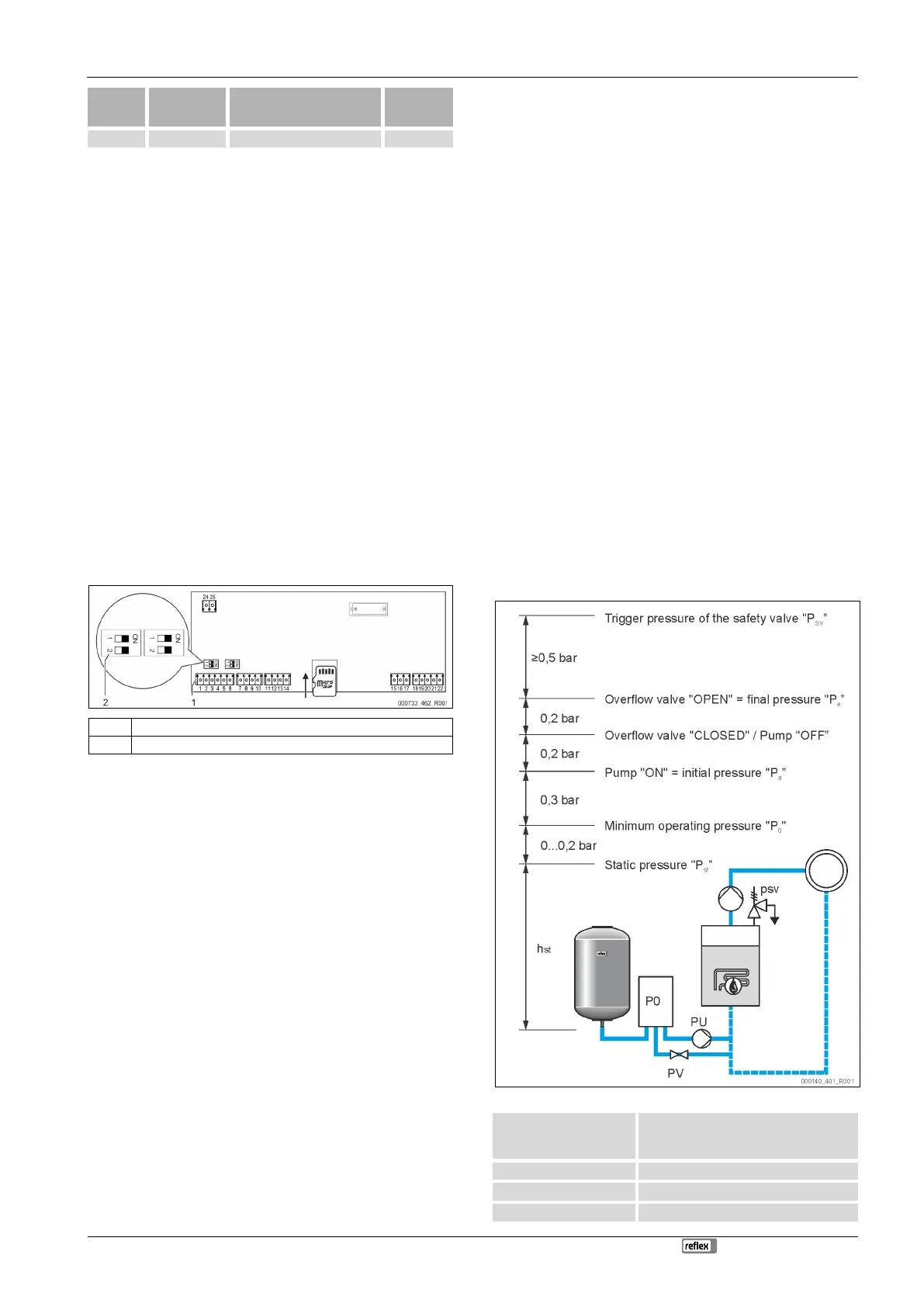

7.5.4.1 Connecting the RS-485 interface

Main circuit board of the Control Touch controller.

Connection terminals for RS-485 connection

Proceed as follows:

1. Use a screened cable to connect the RS-485 interface to the main circuit

board.

• S 1

– Terminal 1 (A+)

– Terminal 2(B-)

– Terminal 3(GND)

2. Connect the cable screen at one side.

• Terminal 18

3. Activate the terminator on the main circuit board.

• Dip switch 1

7.6 Installation and commissioning certificate

Note!

The installation and commissioning certificate can be found at the end

of the operating manual.

Note!

Confirm that installation and start-up have been carried out correctly

using the installation and commissioning certificate. This action is a

prerequisite for the making of warranty claims.

– Have the Reflex Customer Service carry out commissioning and

the annual maintenance.

8.1 Checking the requirements for commissioning

The device will be ready for commissioning when the tasks described in the

"Installation" chapter have been completed. The system designer or an assigned

expert is responsible for carrying out the commissioning. Commission the

storage tank according to the information in the corresponding installation

manual. Note the following information on commissioning:

• The control unit is connected to the primary tank and the secondary tanks,

if provided.

• The water connections of the tanks to the facility system are established.

• The tanks are not filled with water.

• The valves for emptying the tanks are open.

• The facility system is filled with water and gas-vented.

• The electrical connection has been created according to applicable

national and local regulations.

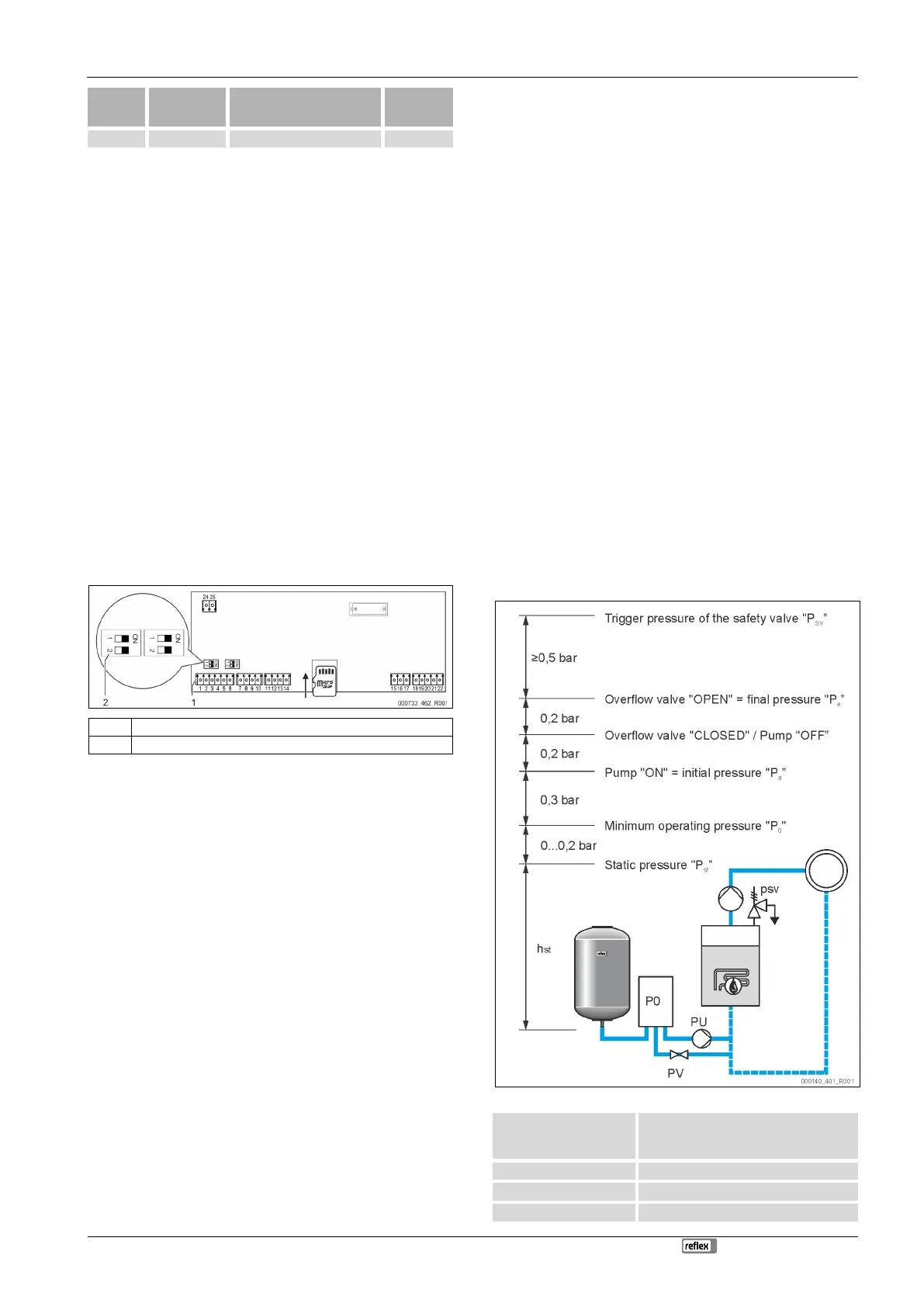

8.2 Variomat switching points

The "P

0

" minimum operating pressure is determined by the location of the

pressurisation. The controller calculates the switching points for the solenoid

valve "PV" and the pump "PU” from the "P

0

" minimum operating pressure.

The "P

0

" minimum operating pressure is calculated as follows:

Enter the calculated value in the start routine

of the controller, see chapter 8.3 "Modifying

the controller's start routine" on page 16 .

for safety temperatures ≤ 100 °C

for safety temperatures = 110 °C

Loading...

Loading...