34 | P36-10 Zero Clearance Direct Vent Gas Fireplace

|

34

installation

CONVERSION FROM NG TO LP

FOR P36-10 USING SIT 829 NOVA GAS VALVE

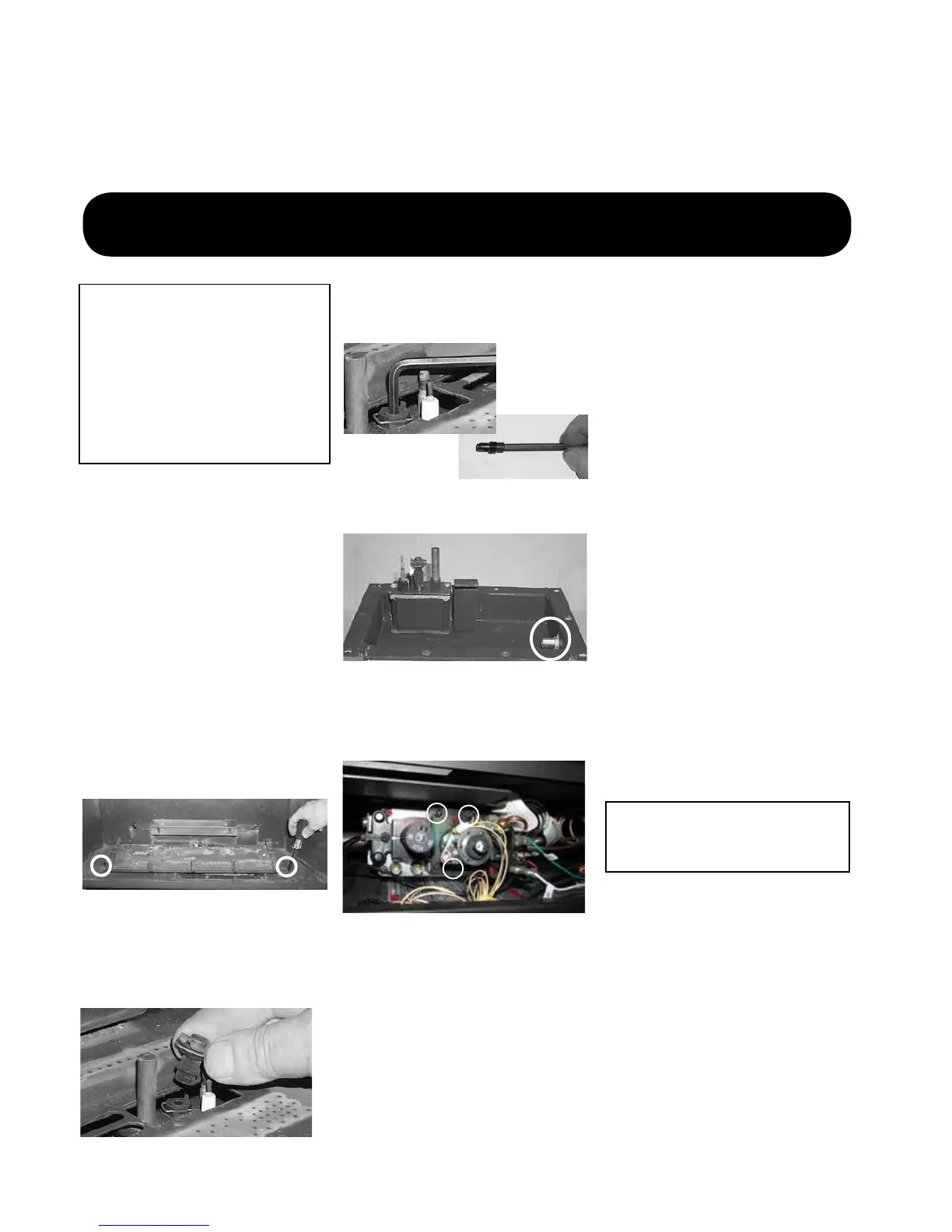

1

10.30.14

919-472

Conversion from NG to LPG for

P36D-10 / P36-10

THIS CONVERSION MUST BE DONE BY A QUALIFIED GAS FITTER

IF IN DOUBT DO NOT DO THIS CONVERSION !!

1. Shut off the gas and electrical supply.

2. Remove the safety screen and face-

plate.

3. Open and remove the glass door.

4. Remove the logs and embers (if already

installed).

5. Remove the 2 screws holding the Burner

Assembly to the rebox base. Push the

Burner Assembly to the left and lift out.

6. Pull off the pilot cap to expose the pilot

orice.

Remove the 2 screws, push Burner Assembly

to the left and lift out.

7. Unscrew the pilot orice with the allen

key; then replace with the LPG pilot

orice and the pilot cap, provided in the

kit.

8. Remove burner orice with a 1/2"

wrench. Use another wrench to hold on

to the elbow behind the orice. Discard

orice.

9. Reinstall new burner orice LPG

stamped #52 and tighten.

Burner Orice

Conversion Kit Contains:

Qty. Part # Description

1 904-390 Burner Orice #52

1 904-529 5/32" Allen Key

1 918-590 Decal "Converted

to LPG"

1 908-528 Red "LPG" label

1 910-037 LPG Injector

(Pilot Orice)

1 910-582 Stepper Motor

1 919-472 Instruction Sheet

Installation of LPG

Conversion Kit:

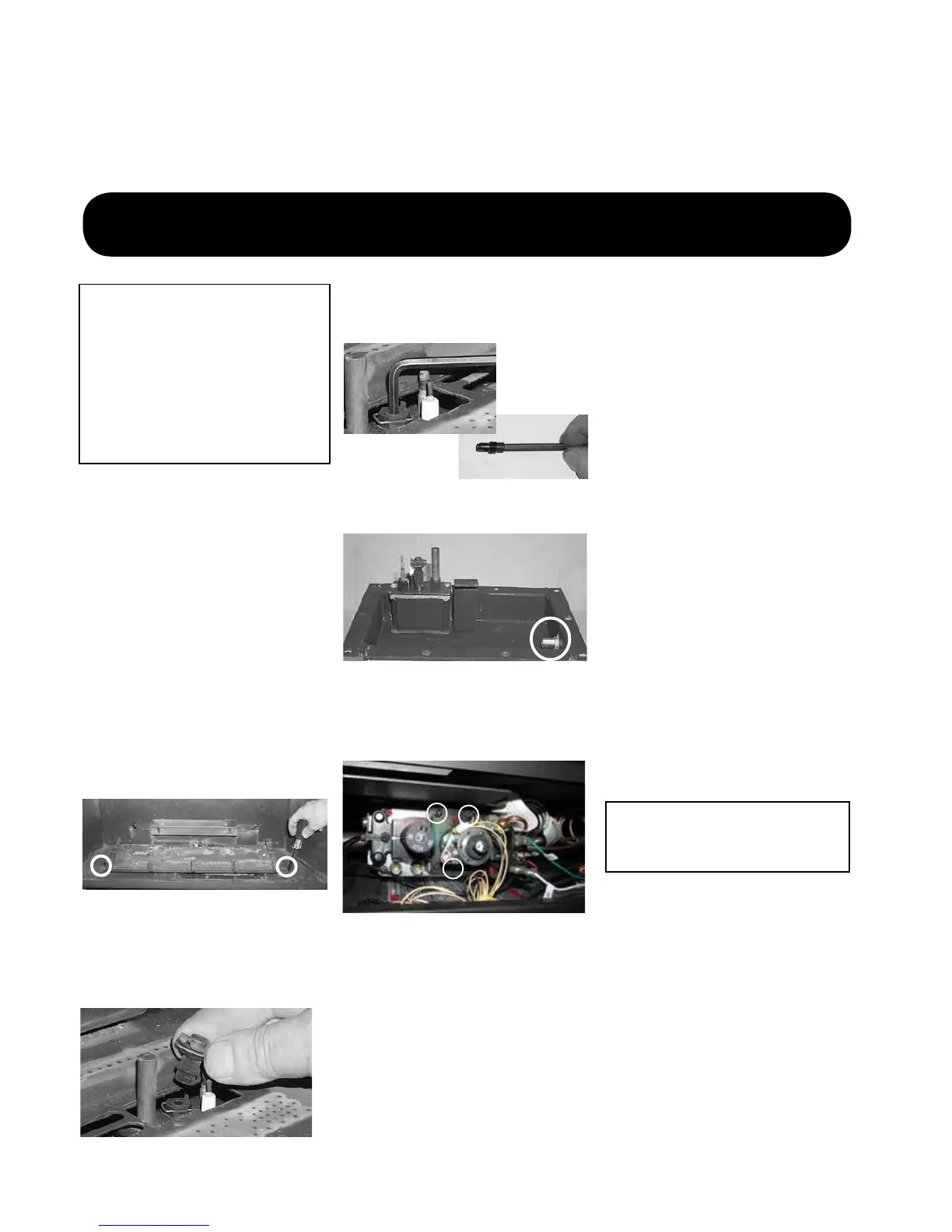

10. Remove NG stepper motor by removing

3 screws in locations shown below–re-

place with LP stepper motor, secure in

place with 3 screws.

Remove NG Stepper motor and

replace with LP Stepper motor

Installer Notice:

These instructions must be left

with the appliance.

11. Check for gas leaks with a proper soapy

solution or leak detector.

12. Check for proper spark between the

ignitor and pilot cap. Refer to "Lighting

Procedure" section of the manual for

lighting sequence.

13. Check pilot flames. Correct flame pattern

has 3 strong blue flames. Adjustment

can be made by turning the slotted

screw at the top right corner of the valve.

Refer to "Maintenance Instructions"

section of the manual for correct flame

patterns.

14. Check inlet (11" WC min) and outlet (10"

WC) pressures. Refer to "Gas Pipe Pres-

sure Testing" section of the manual.

15. Reverse Steps 5 to 1.

16. Attach the label "This unit has been con-

verted to LP" near or on top of the serial

# decal.

17. Replace yellow "NG" label with red "LP"

label.

18. Check operation of flame control.

19. Check for proper flame appearance and

glow on logs.

Loading...

Loading...