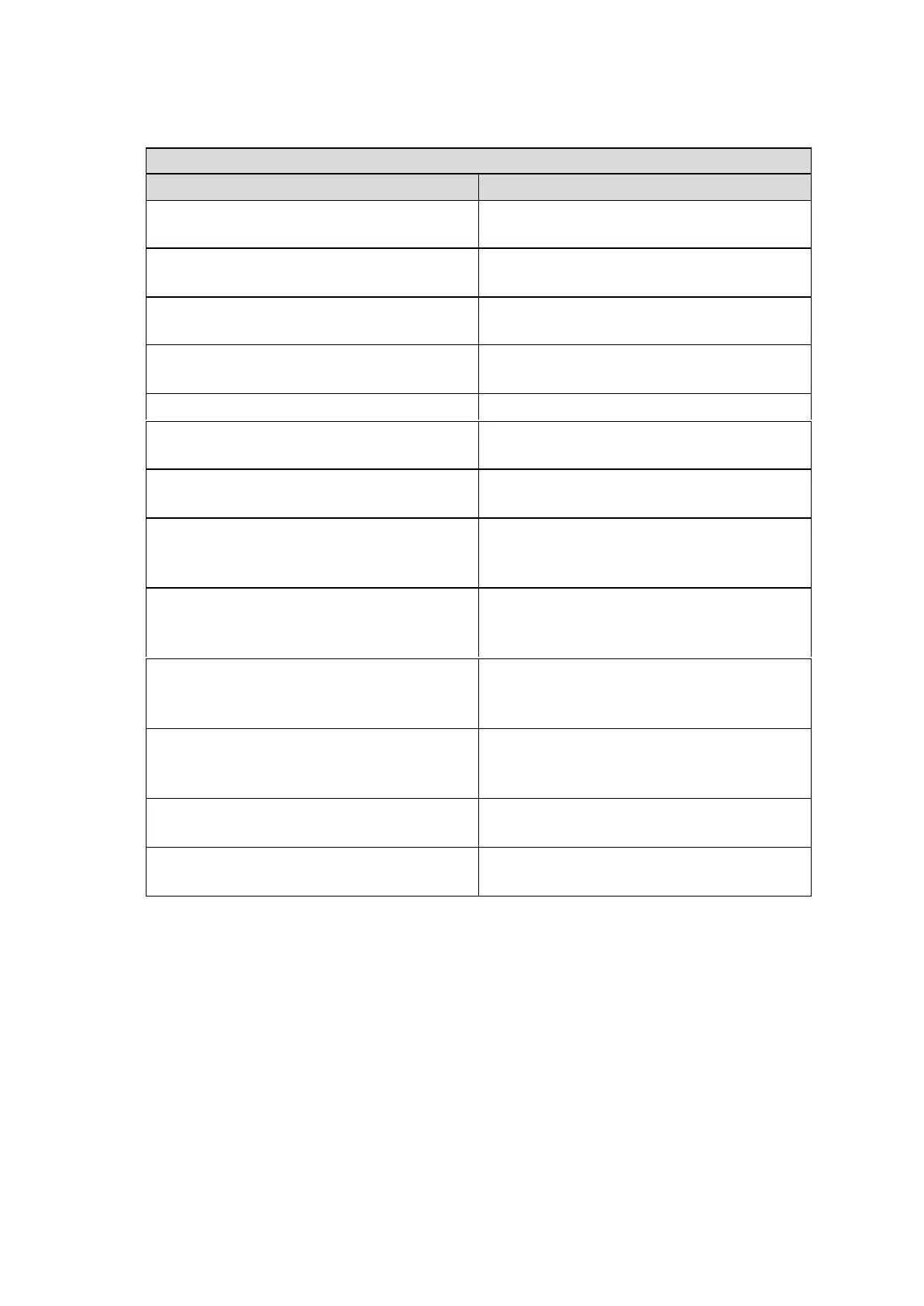

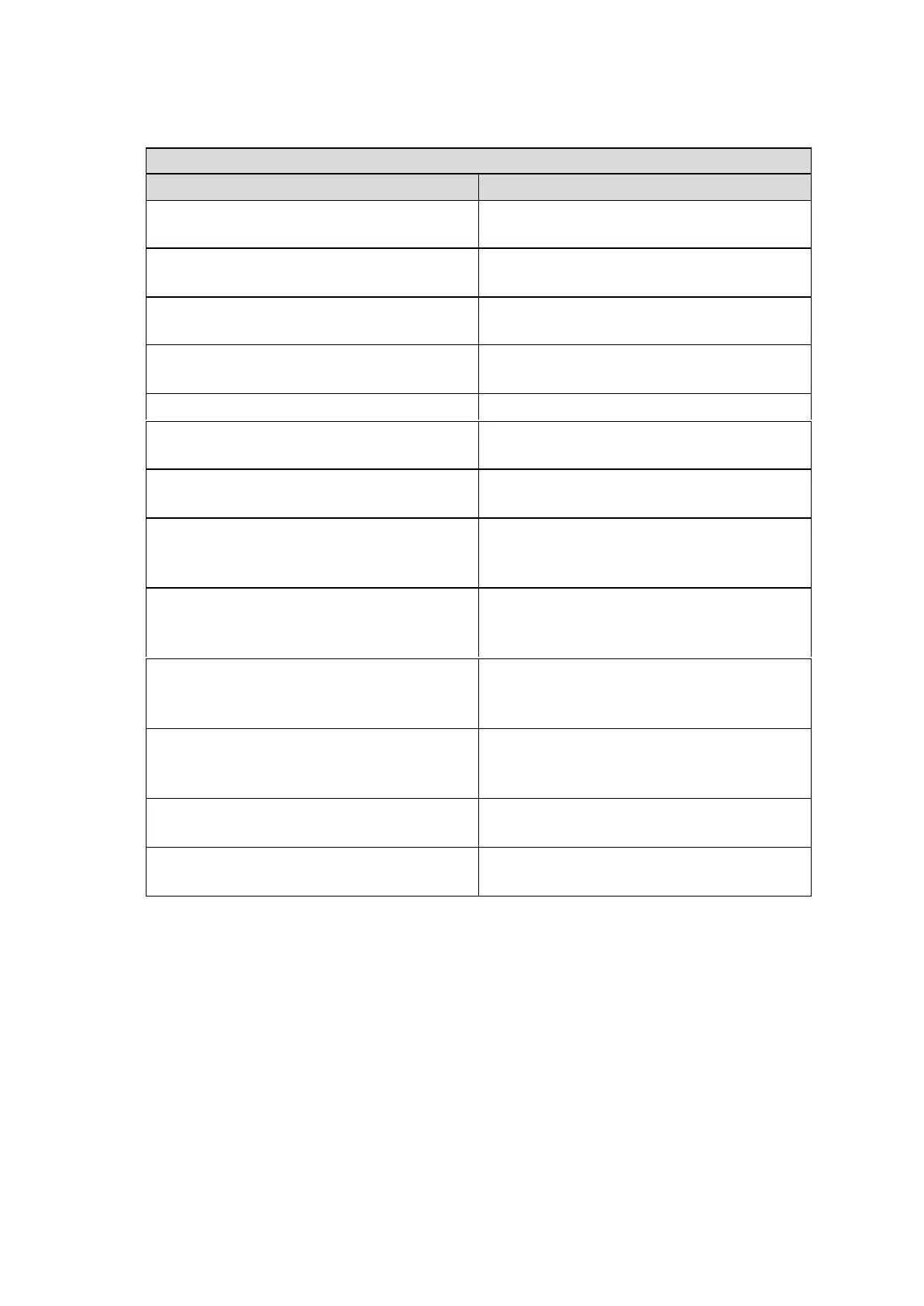

POOR SYSTEM REPEATABILITY

Possible Cause Rectification

Mounting screws not fully tightened Tighten screws to specified torque.

Re-datum probe.

Loose arm Verify tightness of arm on hub

Re-datum probe.

Loose probe Verify tightness of probe in mounting

Re-datum probe

Loose stylus Tighten stylus

Re-datum probe

Swarf on tool tip Remove swarf

Calibration and updating of offsets is

not occurring

Review software

Calibration and probing speeds are

not the same

Review software

Probing is being performed within the

machine acceleration/deceleration

zones

Review software

Probing feedrate is too high for

machine controller

Perform repeatability trials at various

speeds (see section 11.4 of

Installation and User’s Guide)

Temperature variation is causing

excessive movement in the machine

and the TSA

Minimise machine and TSA

temperature changes.

Machines has poor repeatability due

to loose encoders, backlash, tight

slideways and/or accident damage

Perform health check on machine tool

e.g. use Renishaw’s QC10 Ballbar

system

Excess machine vibration Eliminate vibration

Utilise Vlf power input in place of VI

Vlf is being used with inconsistent

probing speed

Change to VI and compare results

18

Loading...

Loading...