2.0 FAULT DIAGNOSIS.

Possible Faults, Causes and Solutions

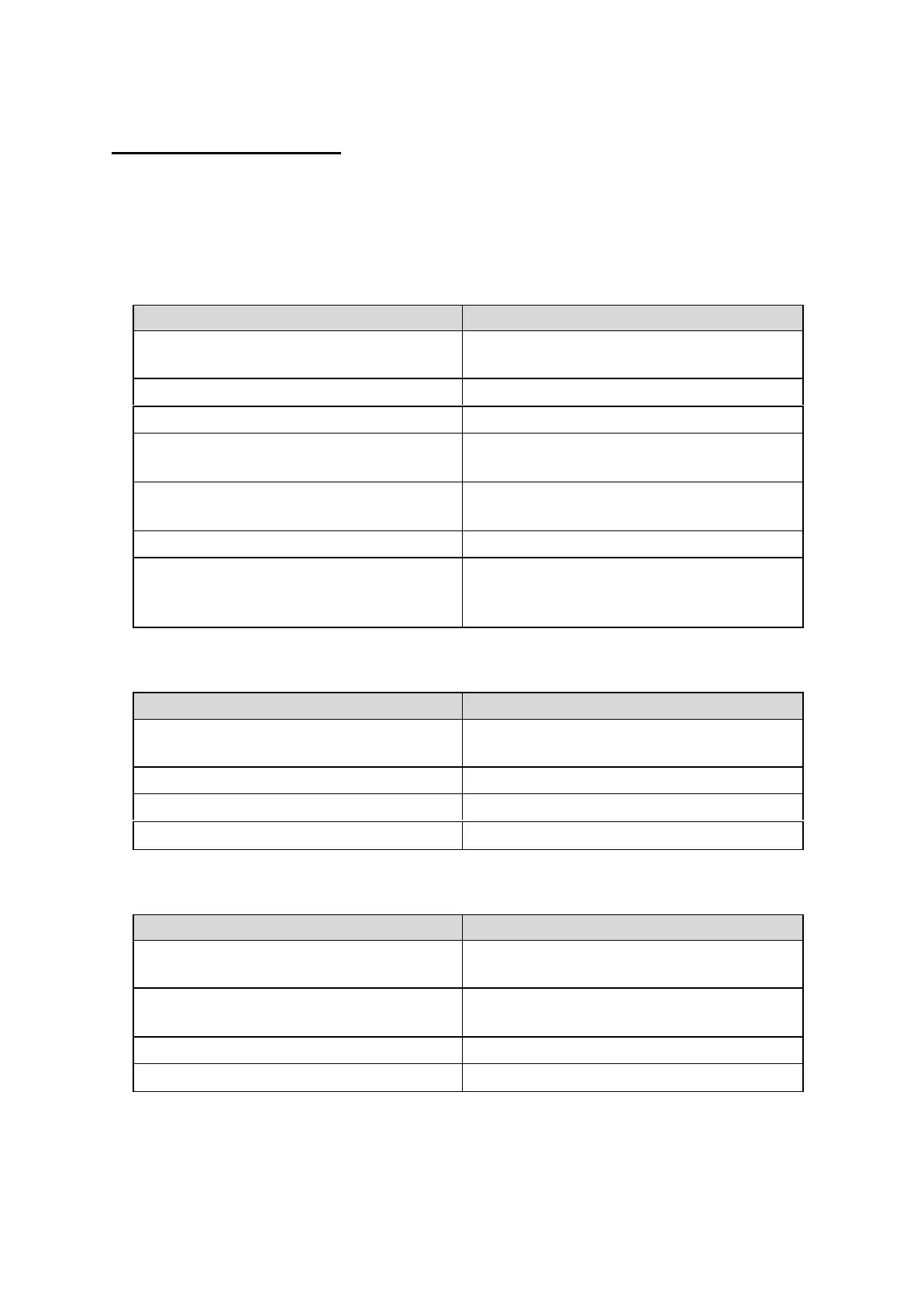

Problem: -

(a) Arm moves into ‘Active’ position, but ‘Active’ confirm LED is not lit.

Possible Causes Rectification

a) Opto switch vanes incorrectly set

or damaged

Consult section 4.2

b) Soft limits PCB defective Consult section 3.2

c) Hard limits PCB defective Consult section 3.3

d) Operating voltage <21.6 v (min)

Measure voltage with suitable meter

and correct supply if possible

e) Motor performance deterioration

Return TSA to Renishaw if

renewal/replacement is required

f) Control PCB fault Replace PCB, section 3.4

g) Wiring fault Check all wiring as per TSA

Installation & User’s Guide (H-2000-

5088-05) section 5.

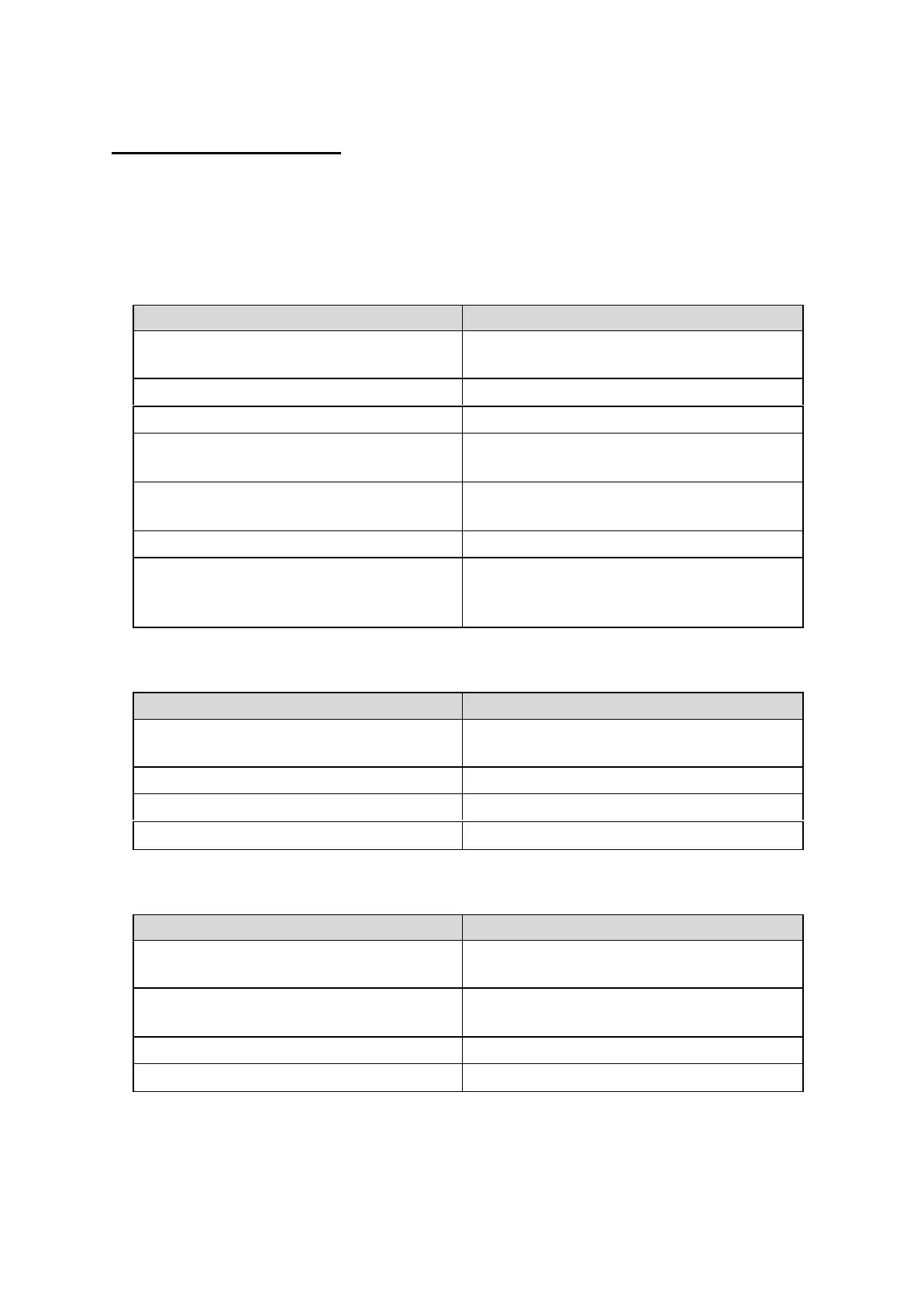

(b) Arm moves into ‘Stow’ position, but ‘Stow’ confirm LED is not lit.

Possible Causes Rectification

a) Opto switch vanes incorrectly set

or broken

Consult section 4.3

b) Hard limits PCB defective Consult section 3.3

c) Control PCB fault Replace PCB, section 3.4

d) Loose mechanics Check all recommended torque values

(c) Arm moves too slow or with excessive judder

Possible Causes Rectification

a) Main bearing seizing up

Return TSA to Renishaw if

renewal/replacement is required

b) Motor defective

Return TSA to Renishaw if

renewal/replacement is required

c) Control PCB fault Replace PCB section 3.4

d) Loose mechanics Check all recommended torque values

3

Loading...

Loading...