17

UBXC-UDXC-IOM (01-24) 1042980-0

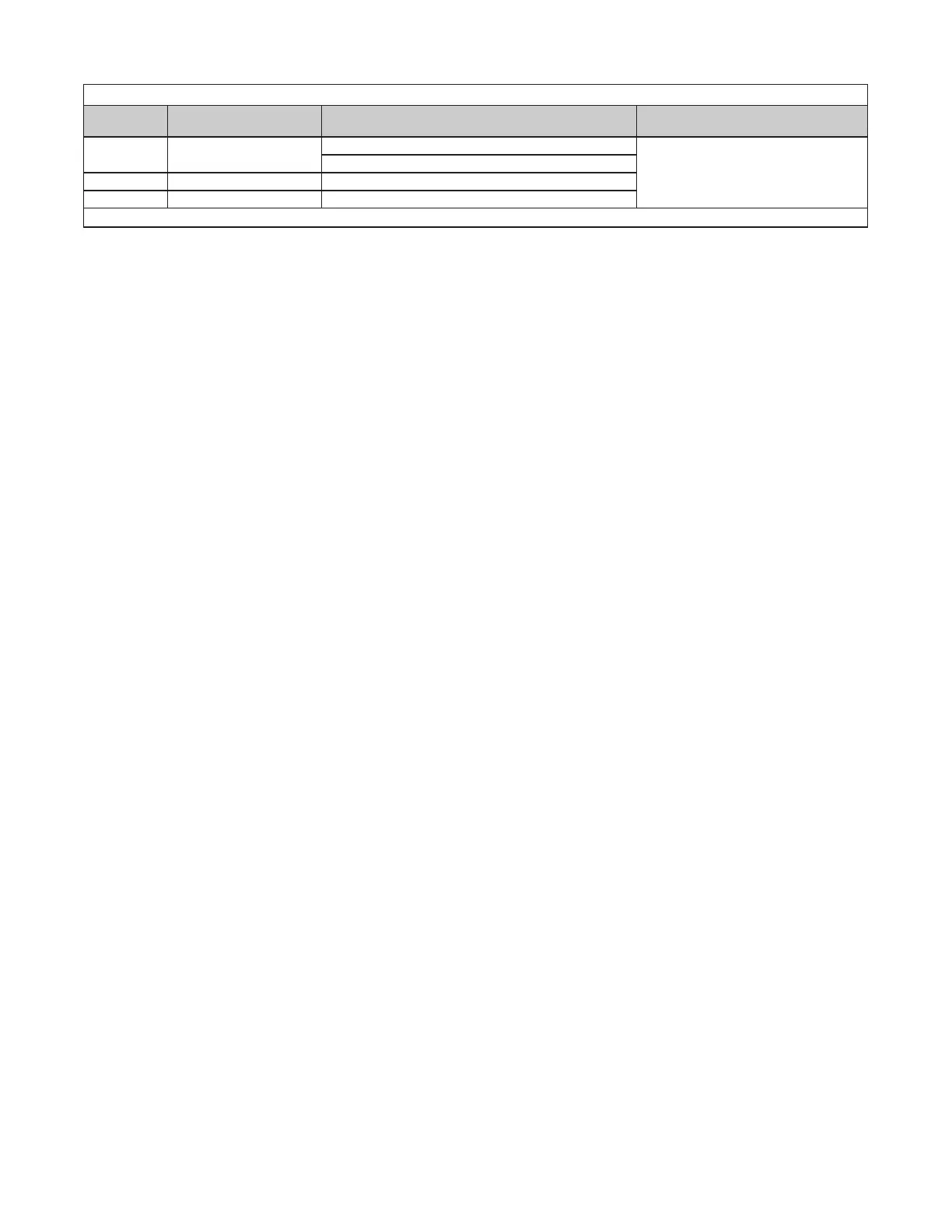

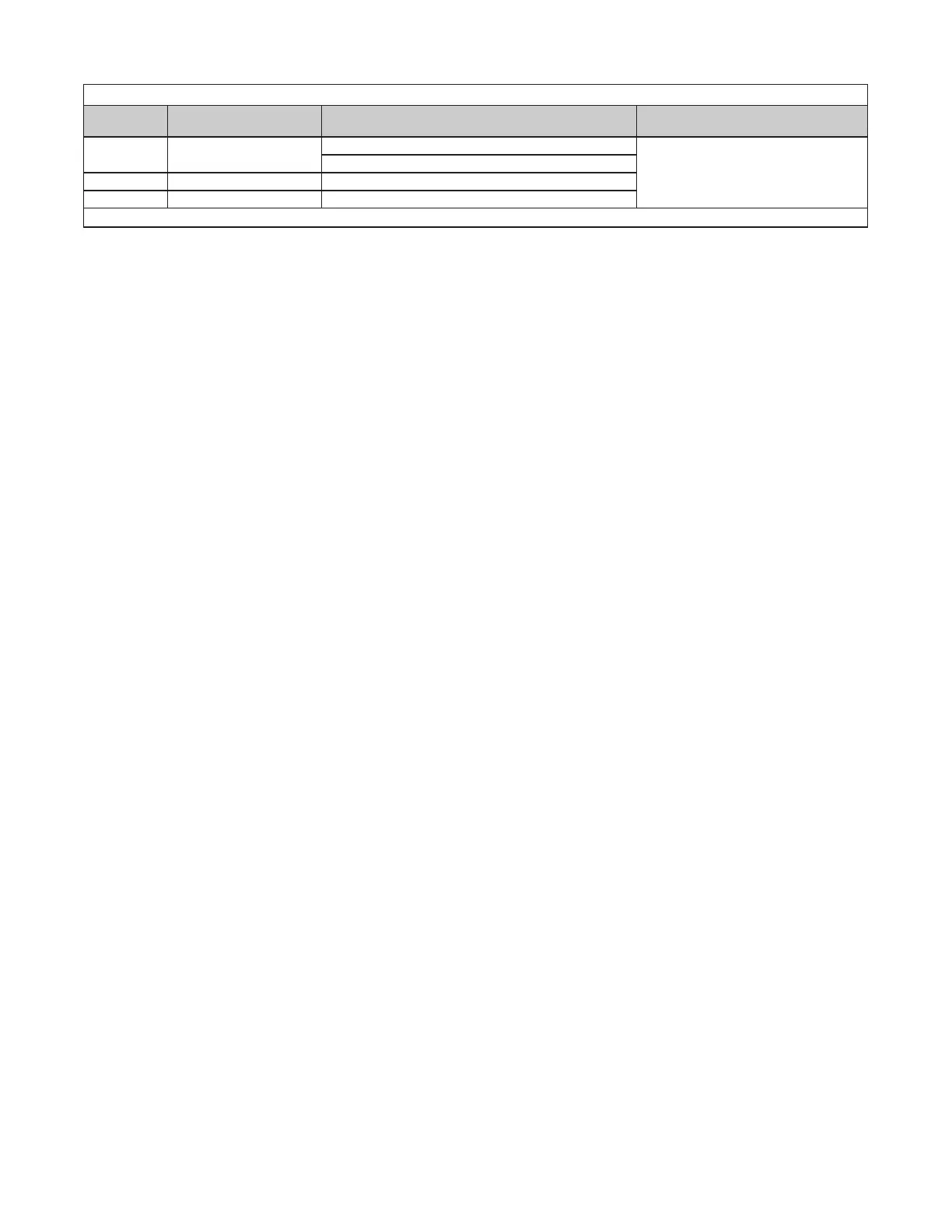

Table 6. Determining Confined Space Combustion Air Requirements

Letter*

Air Source Required Opening Size

Calculate Combustion Air

Requirements

A Air inside building

1 square inch free area per 1000 BTUh

Add total BTUh of all appliances in

confined space and divide by figures

at left for square inch free area size of

each (top and bottom) opening

Never <100 square inches free area for each opening

B Outside air through duct 1 square inch free area per 2000 BTUh

C Direct outside air 1 square inch free area per 4000 BTUh

*See Figure 4.

INSTALLATION

Unpacking and Inspection

• The unit was test-operated and inspected at the factory prior to crating and was in operating condition.

• It is important to note when uncrating the unit that shipping brackets are attached with cabinet screws. When

removing shipping brackets, re-insert ALL screws into the cabinet.

• If, upon removing it from its crate, the unit has been found to have incurred any damage in shipment, document

the damage with the transporting agency and contact an authorized Factory Distributor. If you are an authorized

Distributor, follow the FOB freight policy procedures.

Pre-Installation Checklist

Check the rating plate for the gas specifications and electrical characteristics of the heater to ensure that they

are compatible with the gas and electric supplies at the installation site.

Read this manual and become familiar with the installation requirements of your particular heater.

If you do not have knowledge of local requirements, check with the local gas company or any other local agencies

who might have requirements concerning this installation.

Before beginning, make preparations for necessary supplies, tools, and manpower.

Field-removal of heat exchanger tube support—unit sizes 30–125 (optional): in some cases, the heat exchanger

tubes may have shifted during shipment, causing vibration noise against the support during unit operation. The

primary function of the heat exchanger tube support is to support the heat exchanger tubes during shipment.

This support can be removed without affecting the operation of the unit. It is recommended that the support be

removed prior to installing the unit as follows:

a. Remove discharge air louvers, taking care not to lose springs.

b. Remove and discard two screws that secure heat exchanger support located on top of unit.

c. Remove heat exchanger support through discharge opening and discard support.

d. Reinstall discharge air louvers.

If the heater is to be installed as a separated-combustion unit, it makes sense to convert the heater in

accordance with the instructions provided in the conversion kit (option SC1, refer to Table 7) before

proceeding with the installation.

Check to see if there are any field-installed options (refer to Table 7) that need to be assembled/installed prior

to unit installation. Ensure that all options ordered are at the installation site.

Loading...

Loading...