57

UBXC-UDXC-IOM (01-24) 1042980-0

Flame Rollout Switch Maintenance (Model UDXC, Unit Sizes 30–125)

• The cause of a flame rollout switch (see Figure 20 for location) activating must be determined. Activation of the

manually-reset flame rollout switch could be caused by one or more of the following:

a. Restricted or plugged heat exchanger

b. Too much building exhaust

c. Manifold gas pressure too high

d. Restricted combustion air inlet or exhaust outlet in combination with defective pressure switch

e. Electrical power interruption during operation

f. Unit being operated with line voltage disconnect (24V thermostat is required)

• If a flame rollout switch trips, inspect the burner/control compartment for signs of excessive heat and burned wiring.

If there is damage to the control compartment, repairs must be made before resetting the switch.

• If the compartment appears normal, reset by depressing the red button on the switch (15–20 minutes are required

for the switch to cool sufficiently before resetting). A distinct click will be felt when the switch resets. Operate the

furnace. If the flame rollout switch trips again, determine and correct the cause before resetting the switch.

• If it is determined that the flame rollout switch needs replacing, use only the factory-authorized replacement part

that is designed for that size of heater. The disconnect toggle switch is on the rear of the heater.

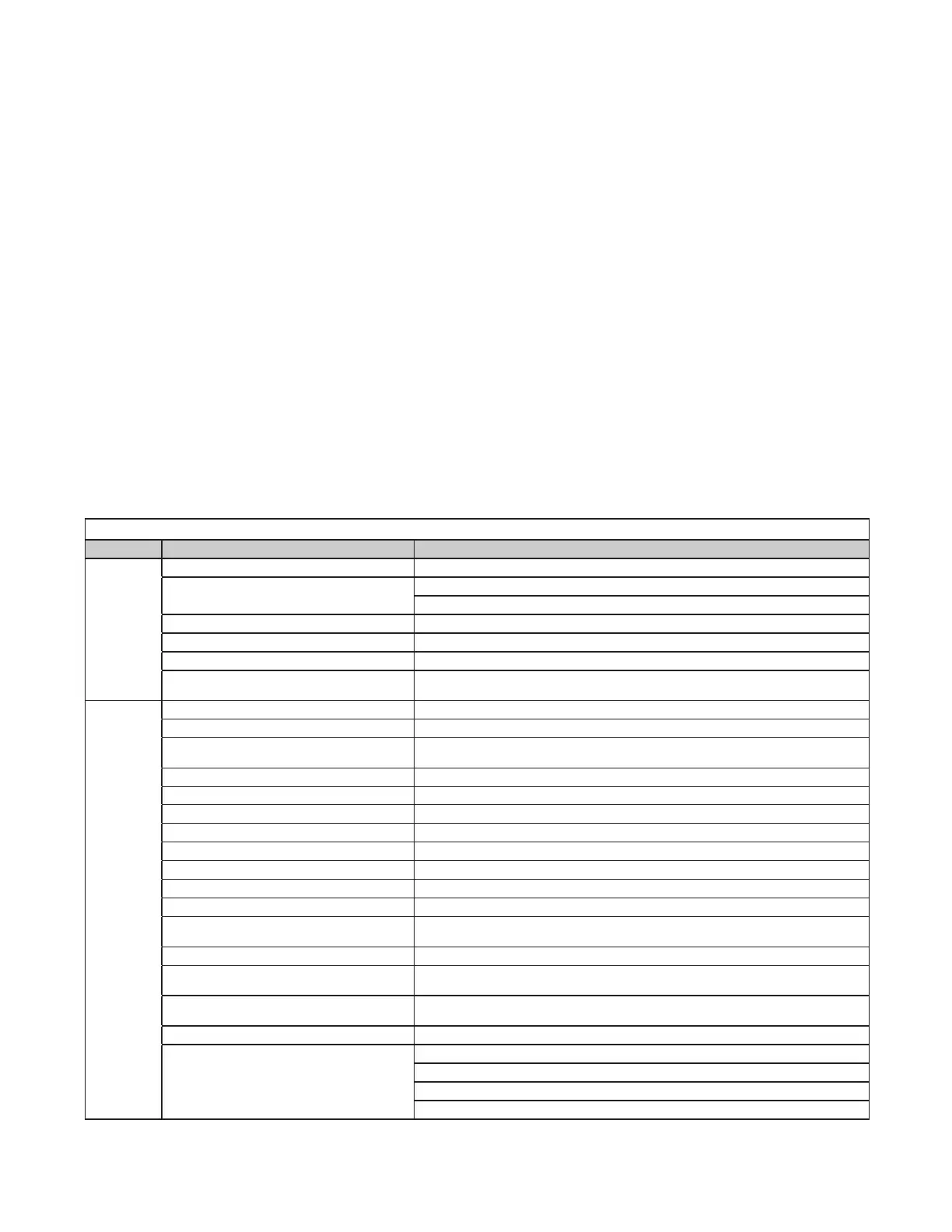

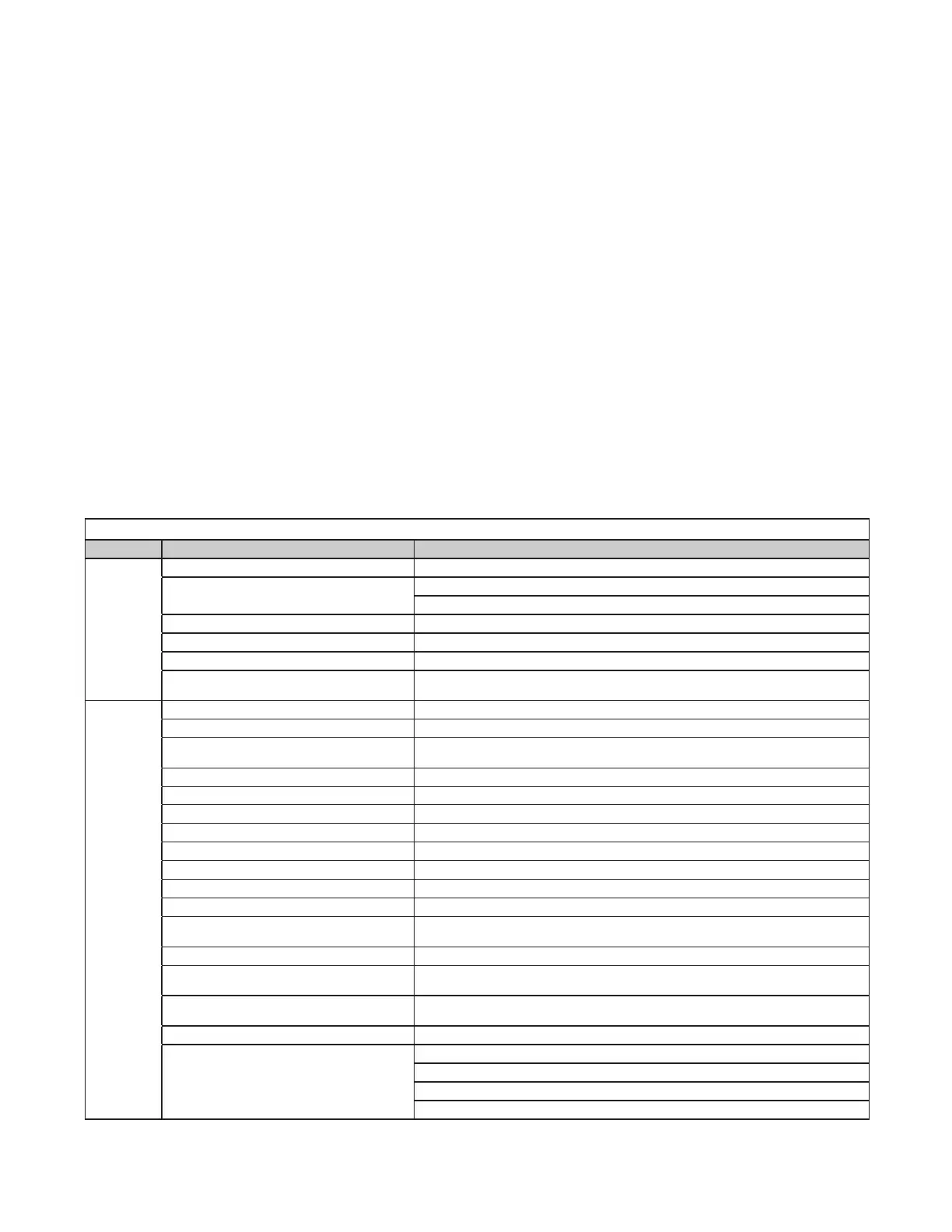

TROUBLESHOOTING

General Troubleshooting

Table 25. General Troubleshooting

Symptom Probable Cause Remedy

A. Venter

motor will

not start

1. No power to unit Turn ON power and check supply fuses or circuit breaker

2. No 24V power to integrated circuit board Turn up thermostat

Check control transformer output

3. Integrated circuit board fuse blown Correct cause and replace fuse (3A, type ATC or ATO, 32VDC)

4. No power to venter motor Tighten connections at circuit board and/or motor terminals

5. Integrated circuit board defective Replace integrated circuit board

6. Defective venter motor Replace venter motor (refer to Venter Wheel and Motor Assembly

Maintenance section)

B. Burner

will not light

1. Manual valve not open Open manual valve

2. Air in gas line Bleed gas line (initial startup only)

3. Gas pressure too high or too low Supply pressure should be 5–14 IN WC for natural gas or 11–14 IN WC for

propane

4. No spark Perform following:

a. Loose wire connections Ensure that all wire connections are solid

b. Transformer failure Ensure that 24V power is available

c. Incorrect spark gap Maintain spark gap at 1/8 inch

d. Spark cable shorted to ground Replace worn or grounded spark cable

e. Spark electrode shorted to ground Replace ceramic spark electrode if it is cracked or grounded

f. Burner not grounded Ensure that integrated circuit board is grounded (terminals P1–9)

g. Circuit board not grounded Ensure that integrated circuit board is grounded to furnace chassis

h. Unit not properly grounded Ensure that unit is properly field grounded to earth ground and properly phased

(L1 to hot lead L2 to neutral)

i. Integrated circuit board fuse blown Correct cause and replace fuse (3A, type ATC or ATO, 32VDC)

j. Faulty integrated circuit board If 24V power is available to integrated circuit board and all other causes have

been eliminated, replace board

5. Lockout device interrupting control

circuit by above causes

Reset lockout by interrupting control at thermostat or main power

6. Interlock door switch open

Close access door or replace switch

7. Pressure switch not closing Perform following:

Ensure that unit is properly vented

Remove obstruction(s) from vent

Replace faulty tubing to pressure switch

Loading...

Loading...