POWER-SPIN® Drain Cleaner

8

Troubleshooting

PROBLEM POSSIBLE REASONS SOLUTION

Cable kinking or

breaking.

Cable is being forced Do Not Force Cable! Let the auger do

the work.

Cable used in incorrect pipe

diameter.

Do not use in lines over 1

1

/

2

" (40 mm).

Use reverse only if cable gets caught in

pipe or to retract cable.

Motor switched to reverse

Cable exposed to acid. Clean cables routinely.

Cable worn out or damaged. If cable is worn or damaged, replace it.

Cable not properly supported. Support cable properly, see instructions.

Cable won’t feed. Cable bearings are dirty or

greasy.

Clean cable and bearings with hot, soapy

water.

AUTOFEED not fully engaged. Be aware and squeeze trigger harder.

Maintenance Instructions

WARNING

Always wear safety glasses and leather

gloves when performing any maintenance.

Drill should be removed from drain cleaner

before any maintenance is performed.

Cleaning

Cable, drum and AUTOFEED should be thor-

prevent the damaging eects of chemicals

and sediment. Clean exterior as needed with

hot soapy water and/or disinfectants. Drain

drum by tipping forward after every use and

cleaning.

Installing Replacement Cable

To Remove Cable From Drum

1. Pull out excess cable from drum.

2. Remove 4 screws on back of drum.

3. Loosen clamp screw and pull end of old

cable from drum and discard.

To Install Replacement Cable

1. Replacement

1

/

4

" (6 mm) x 25' (7,6 m)

MAXCORE® cables are available under

catalog number 42163.

2. To make cable installation easier, com-

pletely uncoil new cable before proceed-

ing. Use caution when removing the ca-

ble from the package. The cable is under

tension and could strike the user.

3. Insert about 12" (0,3 m) of cable through

the front rollers and guide tube into the

drum.

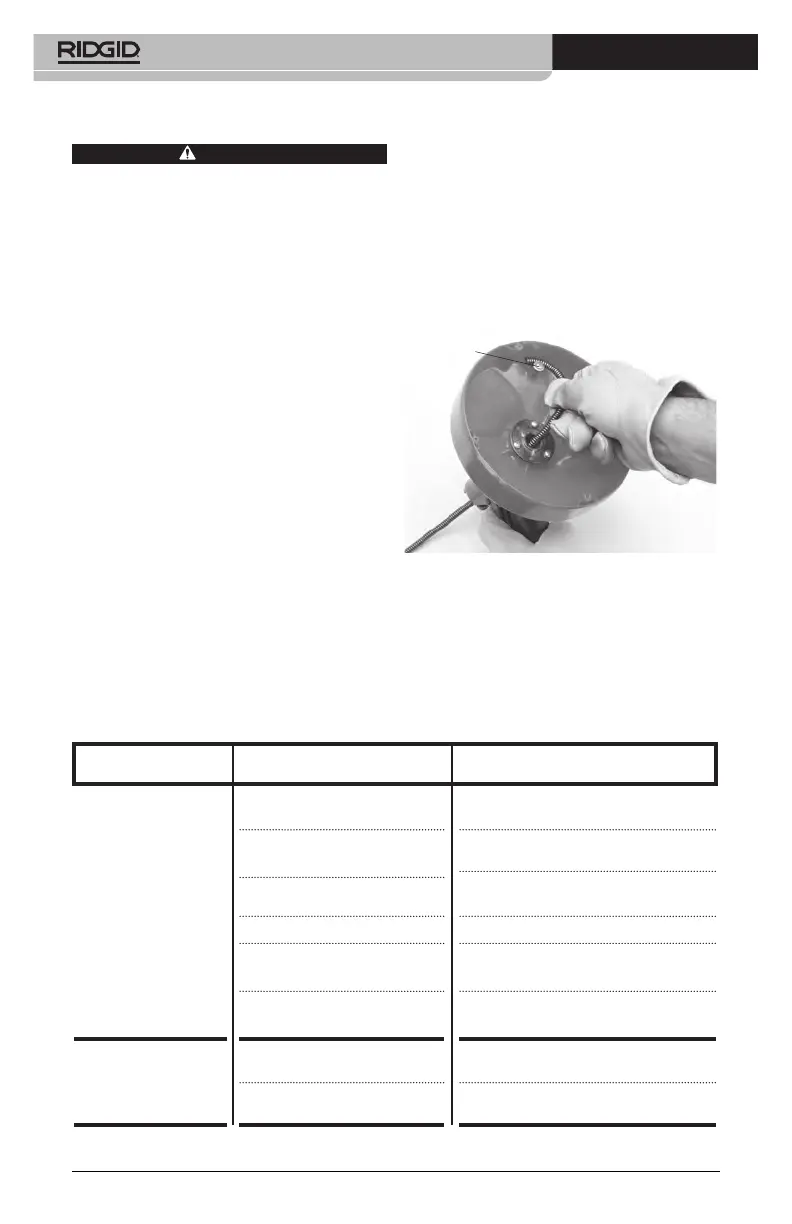

4. Push end of cable into holder and under

clamp screw and washer. Tighten clamp

screw (see Figure 9).

Clamp Screw

Figure 9 – Installing Cable End Into Holder

5. Replace drum back and retighten the 4

screws.

6. Feed cable into drum.

Loading...

Loading...