52

SHUTDOWN

52

APPENDIX

APPENDIX

NOTE

In order to check if the control is functioning properly the following

readings can be taken:

AL Link

24VDC (with S1 Switch On and open circuit). Voltage is variable while

in normal operation depending on data stream.

Pressure Switches

(ie: Gas Pressure, Water Pressure, Flue Pressure, etc) 3.3VDC while

circuit is open.

Safety Switch

(High Limit) 24VDC while open

Flow Meter

5VDC at all times

In addition to the ones listed on the Troubleshooting table, there

are two error messages showing a combination of two potential

failures.

In order to detect which of the combined failures is stopping the

boiler, please go through the following procedures:

1. For Array AR 800: “LWCO/Air inlet block” error message on TS

Boiler screen.

This message shows on touchscreen as a result of two possible

errors:

− Boiler water level below the LWCO probe on the Supply

header.

− Differential between air pressure inside the boiler cabinet

and air pressure of the boiler room higher than 1.4” wc.

In order to discriminate between those two causes, it is suggested

to access the differential air pressure switch inside the boiler

cabinet (left side).

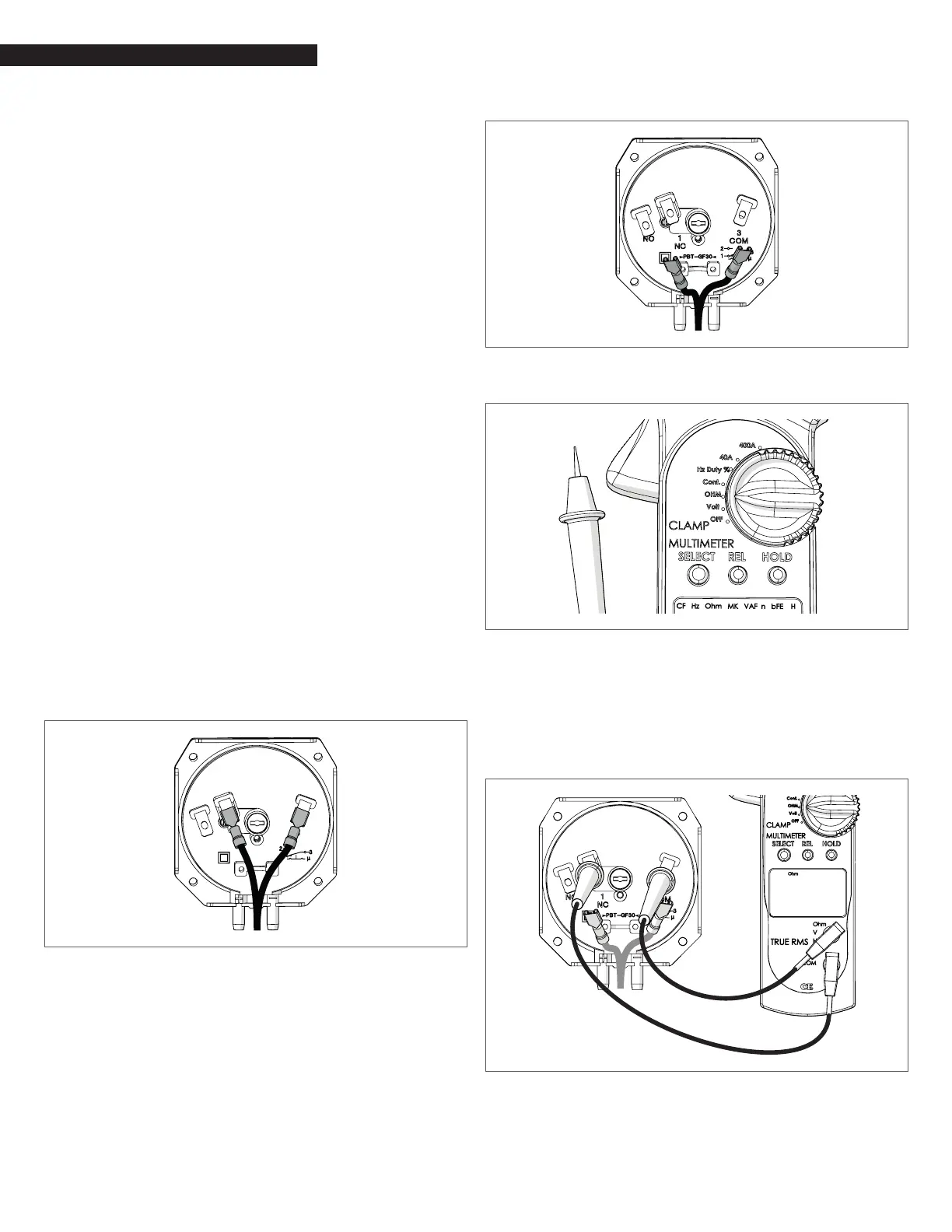

This pressure switch is also normally closed (NC). Conrm it is wired

correctly, with connections on 1 (NC) and 3 (COM), see picture below

1 (NC)

2 (NO)

3 (COM)

Fig. 65

Wired pressure switch

− Disconnect both wires.

Fig. 66

Disconnect wires

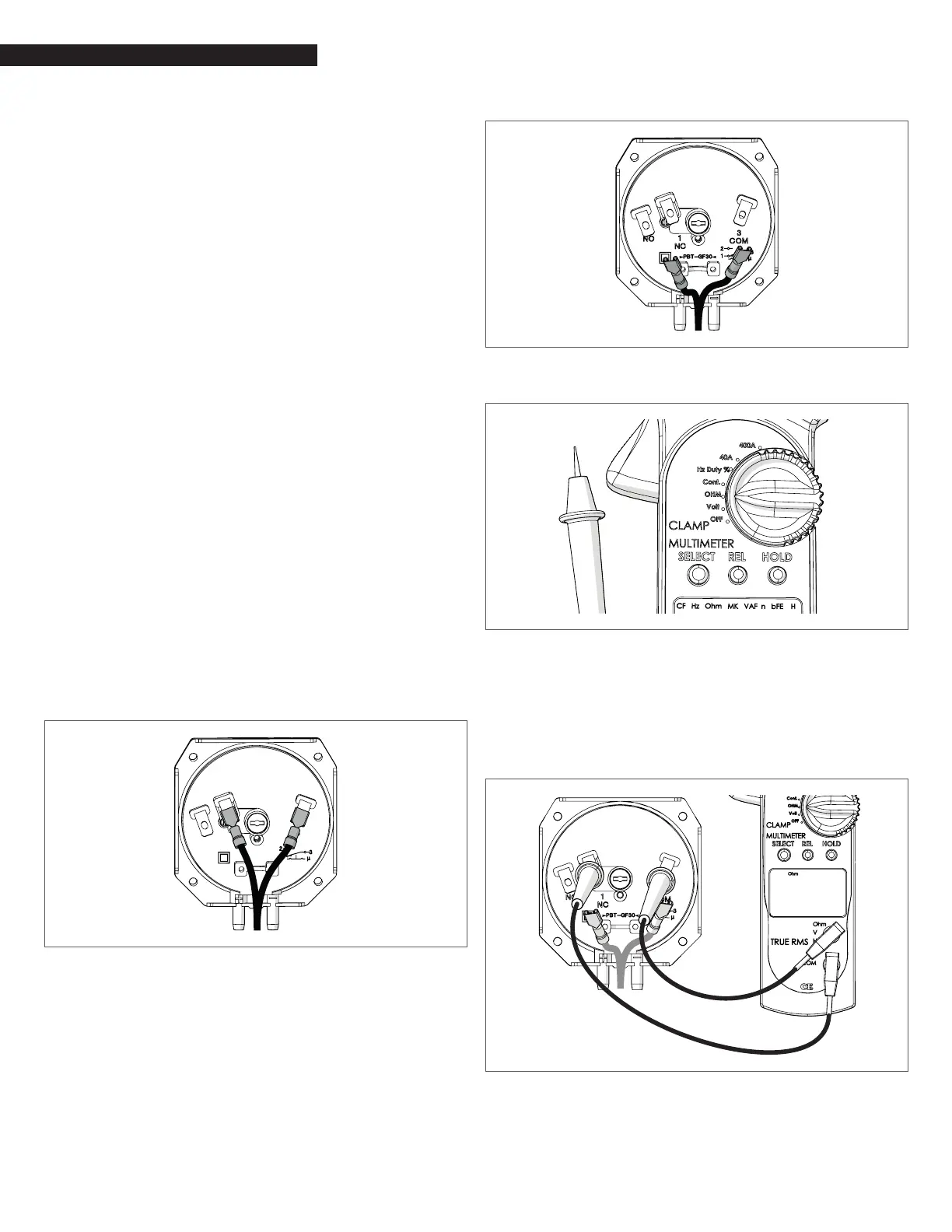

− Set the multimeter device on Ohm (Ω).

Fig. 67

Set multimeter device

− Connect the multimeter probes to 1 and 3 on pressure

switch.

− Check the multimeter display. If the pressure switch

works and is closed (that means the inner pressure of

the condensate trap is lower than 2.2” wc), the display

shows “0” or any other symbol indicating there is electrical

continuity between connections 1 and 3.

1 (NC)

3 (COM)

00.00

Fig. 68

Connect the multimeter probes

Loading...

Loading...