20098824

2

GB

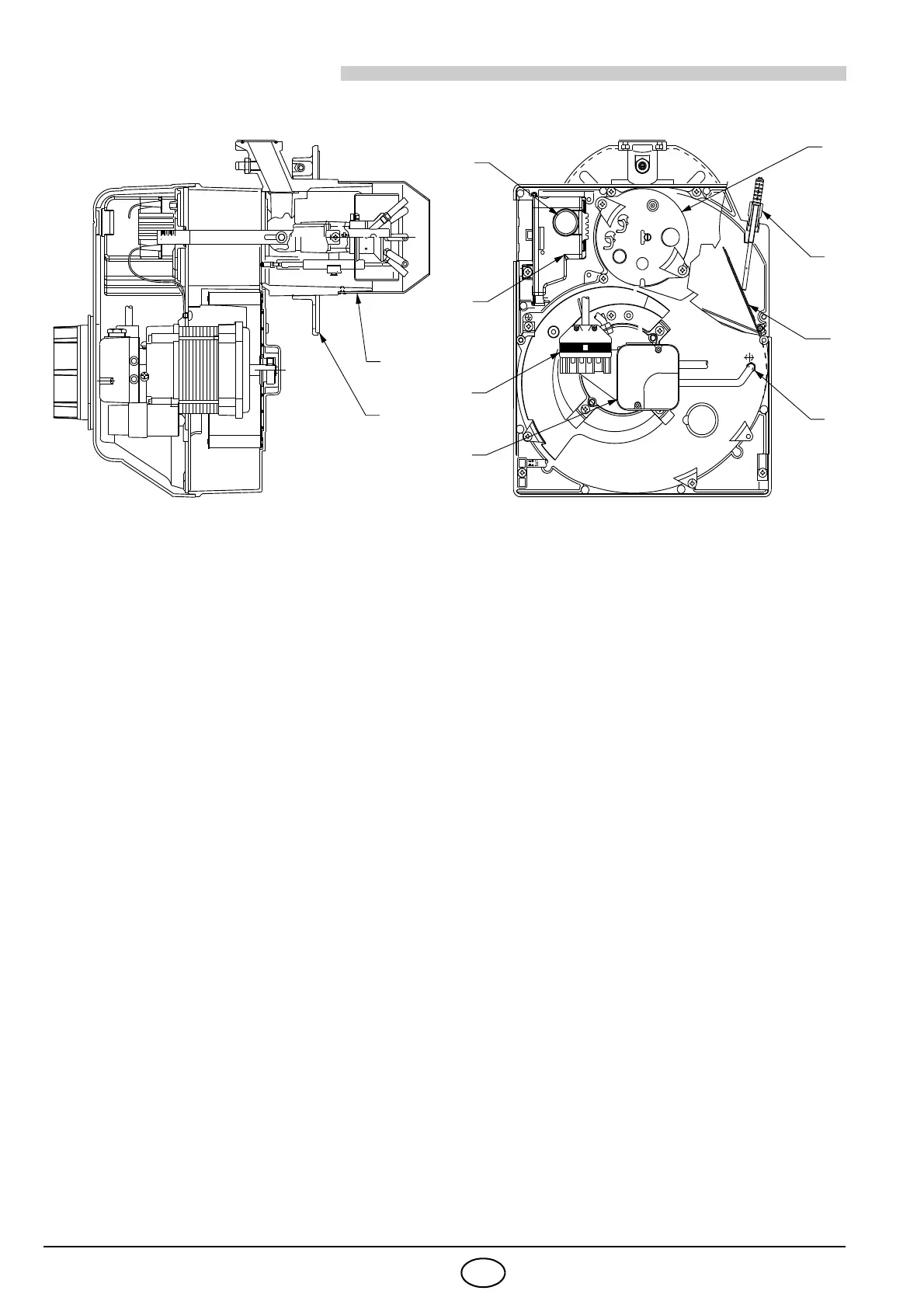

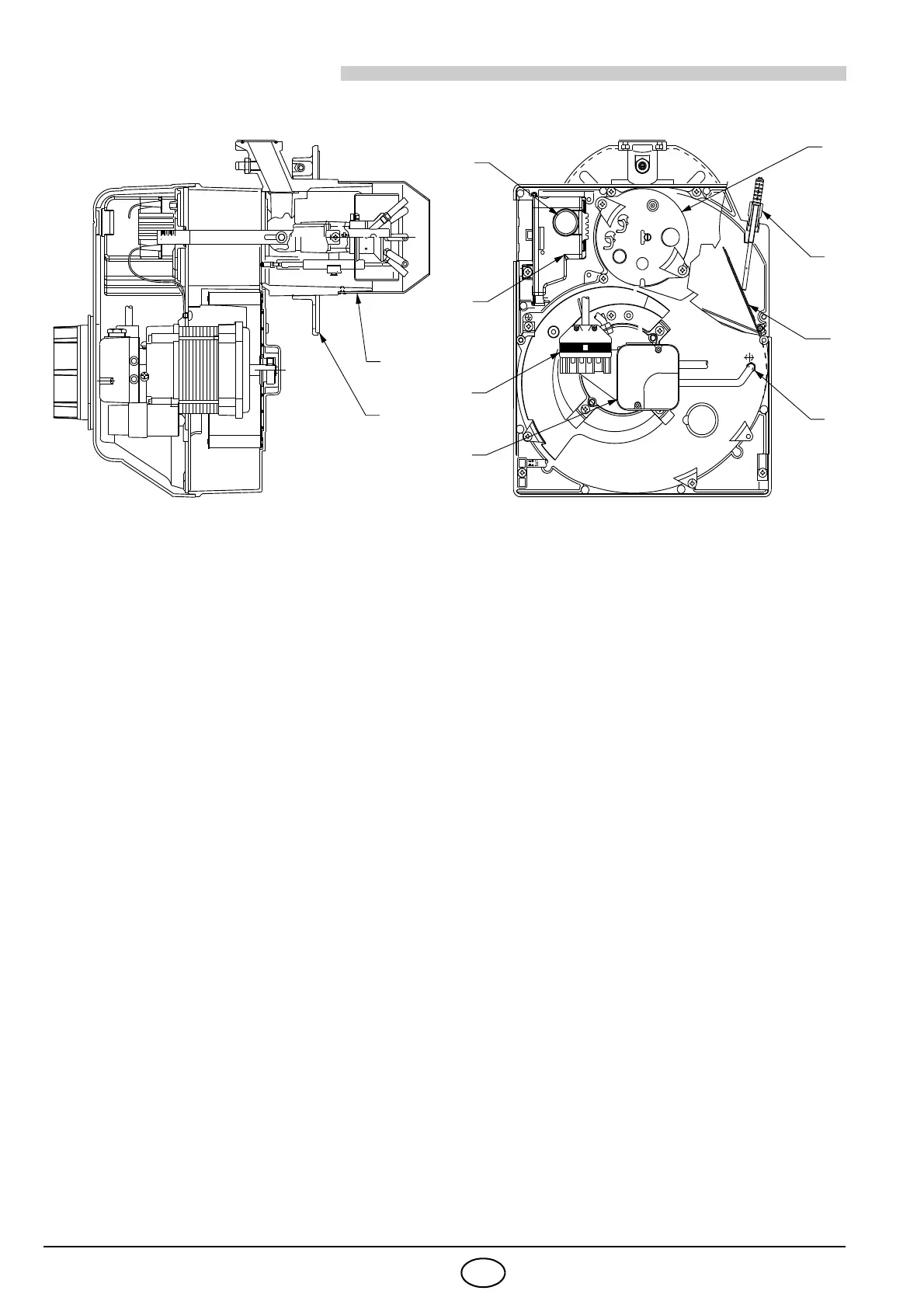

1. BURNER DESCRIPTION

One stage forced draught gas burner.

1 – Pressure switch

2 – 6 pole socket for gas train

3 – Control box with 7 pole socket

4 – Reset button with lock-out lamp

5 – Flange with insulating gasket

6 – Air damper adjustment assembly

7 – Head holder assembly

8 – Pressure test point “+”

9 – Combustion head

10 – Air damper

11 –Air intake

12 – Pressure test point “–”

13 – Gas pressure test point

1.1 BURNER EQUIPMENT

Flange with insulating gasket ........................ No. 1

Screw and nut for flange ................................ No. 1

Remote reset connection................................ No. 1

Screw and nuts for flange to be fixed to

the heat generator...................................... No. 4

Pipe for gas train ............................................ No. 1

Instructions..................................................... No. 2

Spare parts list ............................................... No. 1

1.2 ACCESSORIES (optional):

SOFTWARE DIAGNOSTIC KIT

A special kit is available that, by an optical link to a PC, shows the burner life together with operating hours,

type and number of failures, serial number, etc. To visualise the diagnostics proceed as follows:

Connect the kit supplied separately to the control box socket.

Reading of the information begins when the software programme included in the kit starts.

REMOTE RESET KIT

The burner has a remote reset kit (RS) consisting of a connection and a push-button operating at a dis-

tance of 20 metres max.

In order to install it remove the protective lock-out installed at the factory and insert the lock-out supplied

with the burner (see electrical diagram on page 10).

MULTIBLOC ROTATION KIT

There is a special kit available that can be used to install the burner turned 180°, as illustrated on page 8 in

position 5 in the section entitled "3.2 WORKING POSITION". This kit is designed to ensure the gas train

valve works properly. The kit must be installed in conformity with laws and local regulations.

Loading...

Loading...