20098824

12

GB

WARNING

Tighten the screws (7) completely (without locking them); then lock them with a torque wrench setting of

3 - 4 Nm.

Check there are no gas leaks from the screws during these operations.

4.3 AIR DAMPER SETTING, (fig. 8, page 11)

Do not carry out the first ignition with the air

damper lower than set point 1.

The air damper leaves the factory set on set point 1.

To vary the setting proceed as follows:

Loosen the nut (9) and the screws (8).

Once you have done, tighten the nut (9).

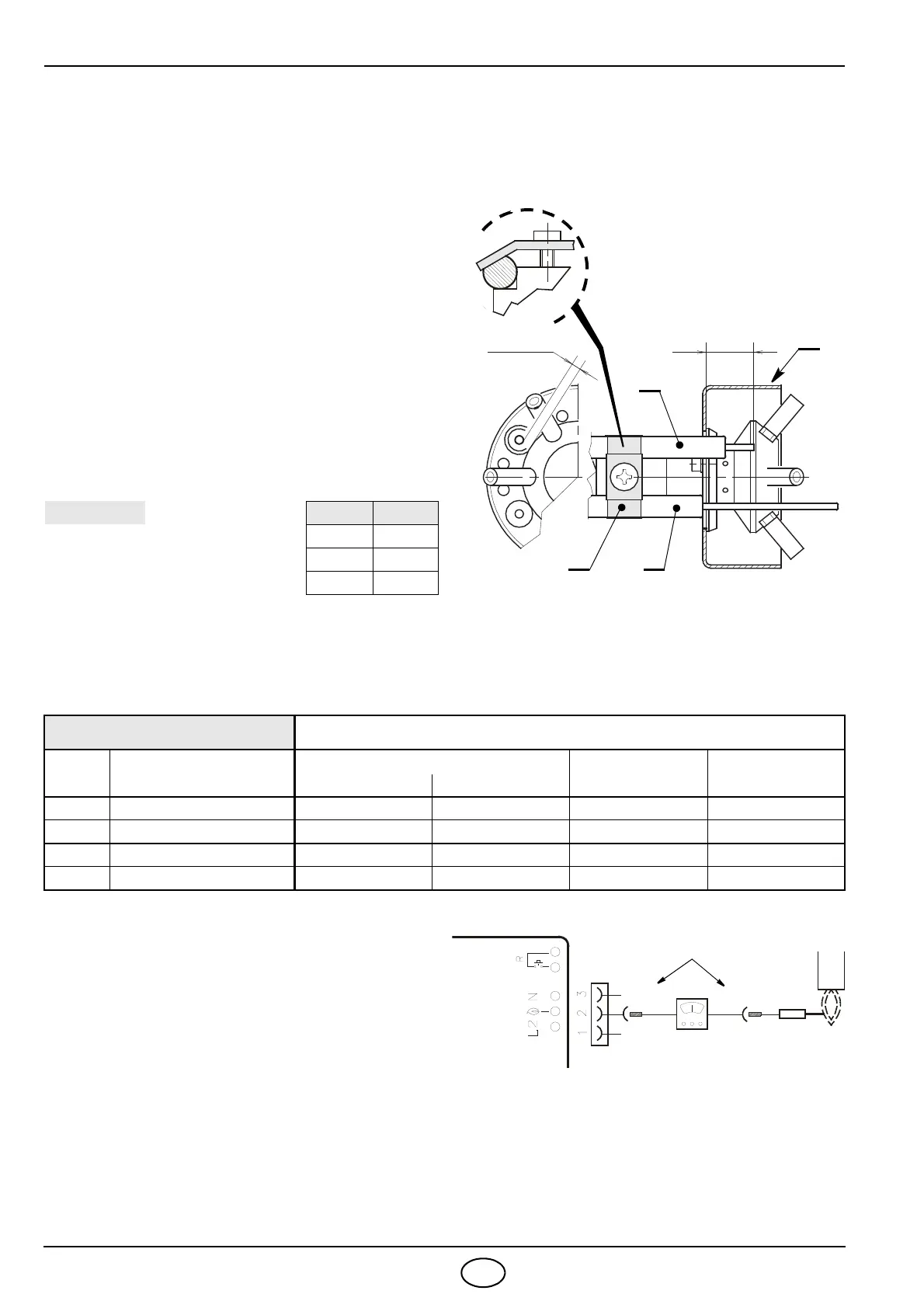

4.4 PROBE-ELECTRODE POSITIONING

Ensure that the plate (3, fig. 9) is always inserted in the

flattening of the electrode.

Lean the probe insulator (4) against the cup (2).

4.5 COMBUSTION CHECK

It is advisable to set the burner according to the type of gas used and following the indications of the table:

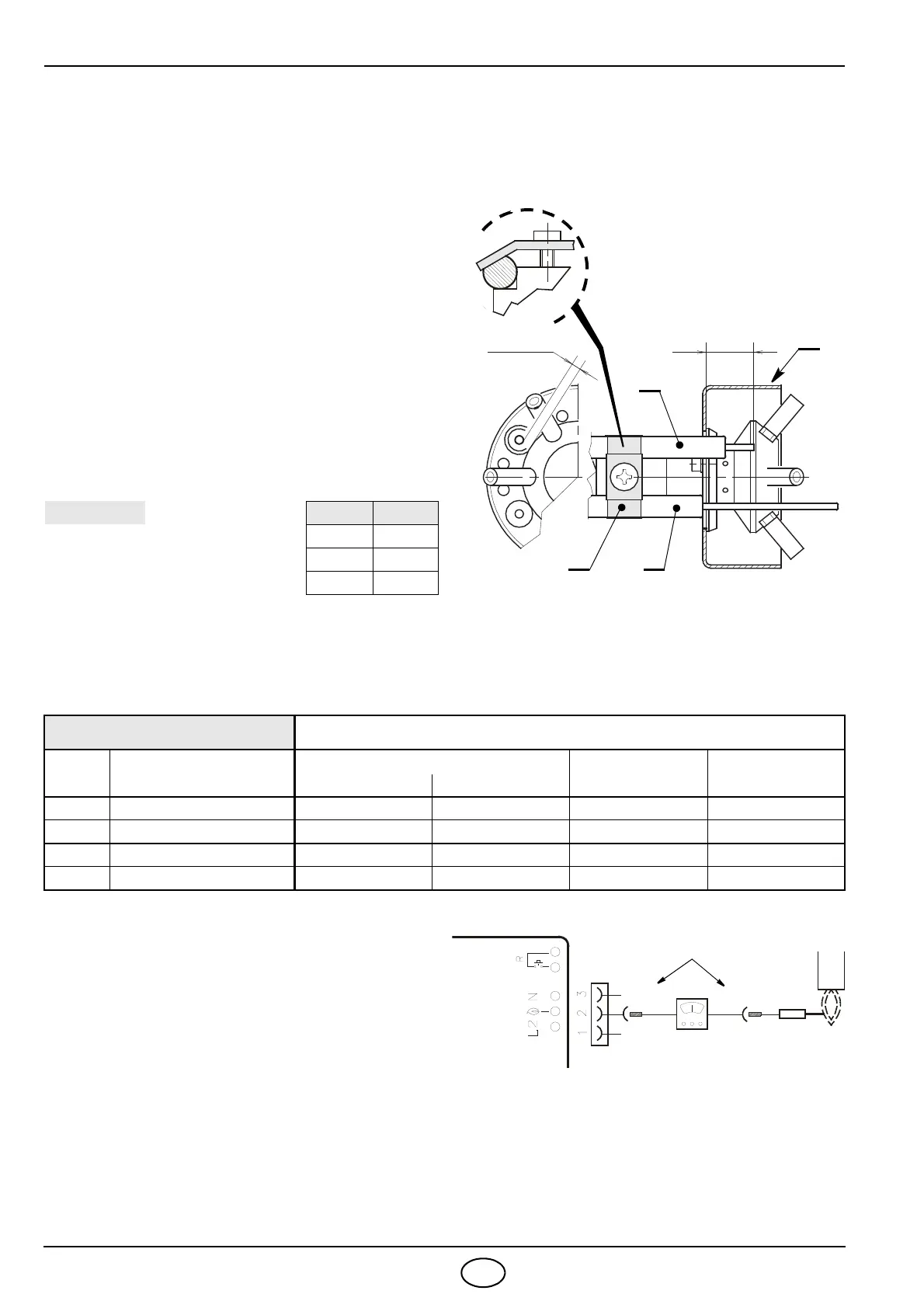

IONIZATION CURRENT

The minimum current necessary for the con-

trol box operation is 5 µA.

The burner normally supplies a higher cur-

rent value, so that no check is needed. Any-

way, if you want to measure the ionization

current, you have to open the connector

(CN1 see electrical scheme page 10) fitted

on the wire and insert a microammeter.

EN 676

AIR EXCESS: max. output λ ≤ 1.2 – min. output λ ≤ 1.3

GAS

Theoretical max. CO

2

0 % O

2

Setting CO

2

%

CO

mg/kWh

NO

x

mg/kWh

λ = 1.2 λ = 1.3

G 20 11.7 9.7 9.0

≤ 100 ≤ 170

G 25 11.5 9.5 8.8

≤ 100 ≤ 170

G 30 14.0 11.6 10.7

≤ 100 ≤ 230

G 31 13.7 11.4 10.5

≤ 100 ≤ 230

D6088

± 0.3

3.5 ± 0.3

A

Fig. 9

1

3

2

4

TYPE A (mm)

912 T2 30

913 T2 31

914 T2 31

KEEP TO GIVEN DISTANCES

ATTENTION

Loading...

Loading...