20098824

11

GB

4. WORKING

4.1 COMBUSTION ADJUSTMENT

The application of the burner to the heat generator, adjustment and testing must be carried out observing

the instruction manual of the boiler, including verification of the CO and CO

2

concentration in the flue gases,

their temperatures and the average temperature of the water in the generator.

To suit the required appliance output, choose the proper setting of the combustion head, and the air damper

opening.

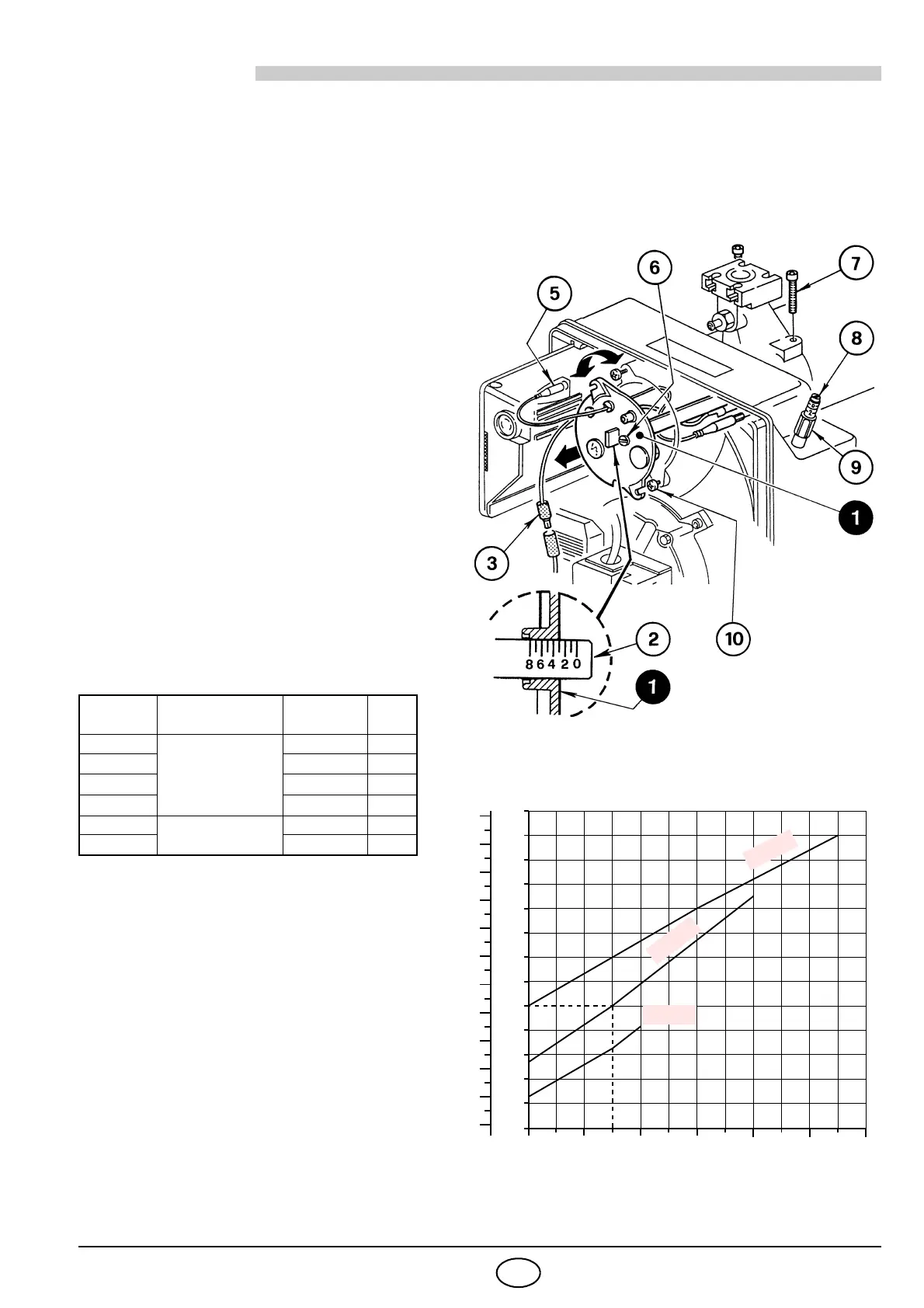

4.2 COMBUSTION HEAD SETTING,

(see fig. 8)

The combustion head is set in the factory

(see Tab.)

Setting depends on the output of the burner.

Rotate the setting screw (6) in a clockwise or

anticlockwise direction until set point marked

on the regulating rod (2) is level with the out-

side plane of the head assembly (1).

Figure 8 shows the head regulating rod set

on set point 3.

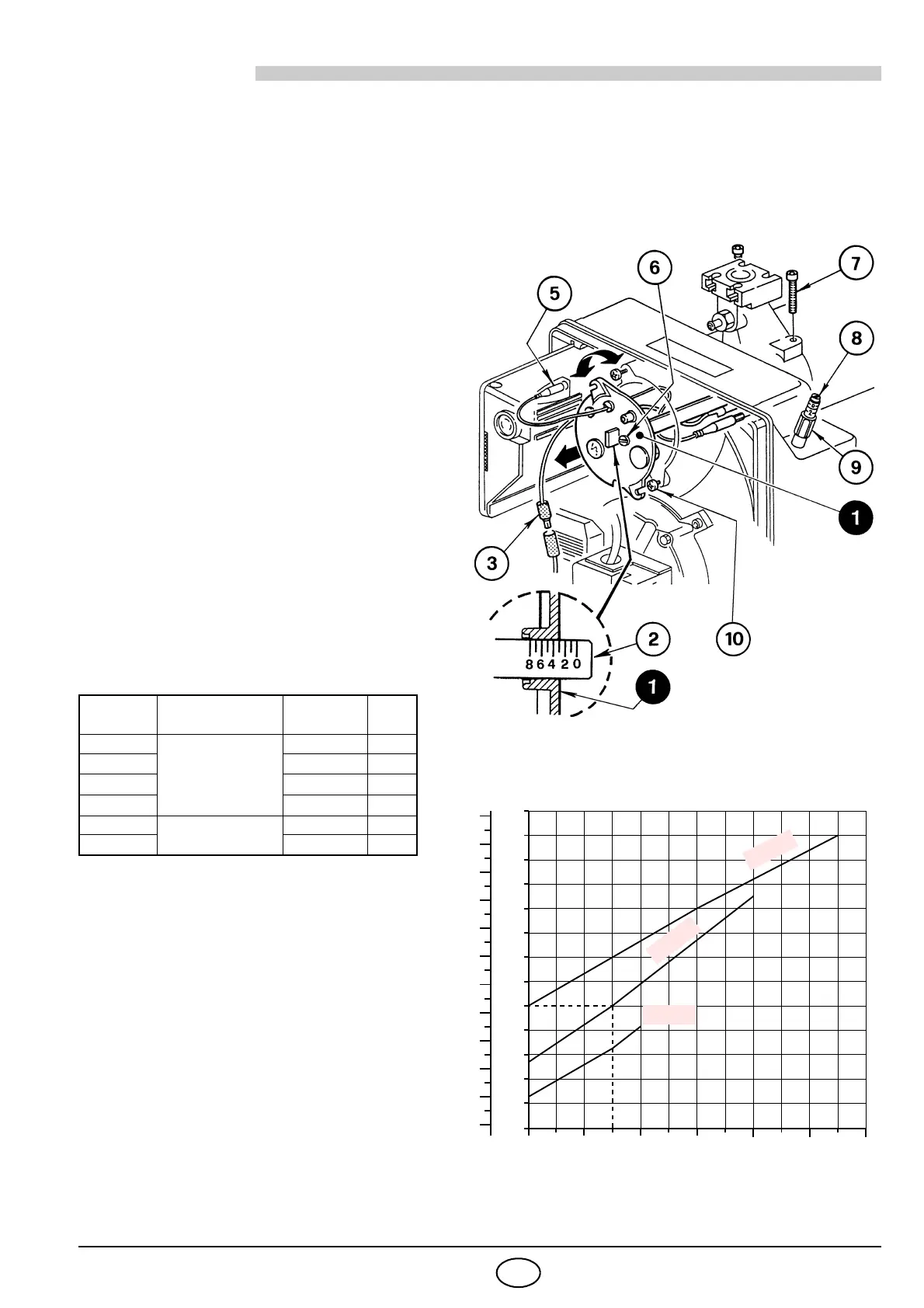

Example for burner type 913 T2:

The burner is installed in a 100 kW heat gen-

erator. Taking an efficiency level of 90% the

burner should give an output of app. 110 kW

with the regulating rod set at set point 3 as

shown in the diagram.

The diagram is for indication purposes: to as-

sure good working from the burner we sug-

gest adjusting the combustion head

according to the heat generator.

REMOVING THE HEAD ASSEMBLY

Proceed as follows to remove the head as-

sembly:

Disconnect the connections (3 and 5) and

loosen the screws (10).

Unscrew and remove the screws (7), pull

out the head assembly support (1) turning

it slightly to the right.

Take care not to change the setting posi-

tion on the elbow-bracket (2) during dis-

mantling.

REASSEMBLING THE HEAD ASSEMBLY

Follow the above instructions in reverse, re-

turning the head assembly (1) to its original

position.

CODE HEAD SETTING MODEL TYPE

20098812 1 BS2F 912T2

20098813 BS2F-GPL 912T2

20098814 BS3F 913T2

20098815 BS3F-GPL 913T2

20098817 2 BS4F 914T2

20098818 BS4F-GPL 914T2

10

30

50

70

90

110

130

150

170

190

210

230

250

270

kW

0

2

4

6 8

10

12

10.000

50.000

90.000

130.000

170.000

210.000

kcal/h

Loading...

Loading...