20068428

54

Maintenance

Gas filter

Replace the gas filter when it is dirty.

Flame inspection window

Clean the glass of the flame inspection window.

Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics intact,

especially the flue gas temperature and combustion chamber

pressure.

Combustion

If the combustion values found at the start of the intervention do

not satisfy current standards or anyway indicate a poor state of

combustion (consult the table below), contact the Technical As-

sistance Service for the necessary adjustments.

Tab. V

7.2.4 Safety components

The safety components should be replaced at the end of their life

cycle indicated in the Tab. W.

The specified life cycles do not refer to the warranty terms indi-

cated in the delivery or payment conditions.

Tab. W

7.2.5 Measuring the ionisation current

The burner is fitted with an ionisation system to check that a

flame is present.

The minimum current for control box operation is 4 µA. The Op-

erator Panel visualises “30%” (see

"Parameter list" at page 47,

parameter no. 954).

The burner provides a much higher current, so controls are not

normally required.

However, if it is necessary to measure the ionisation current, dis-

connect the plug-socket on the ionisation probe cable and insert

a direct current microammeter with a base scale of 100 µA - see

Fig. 37.

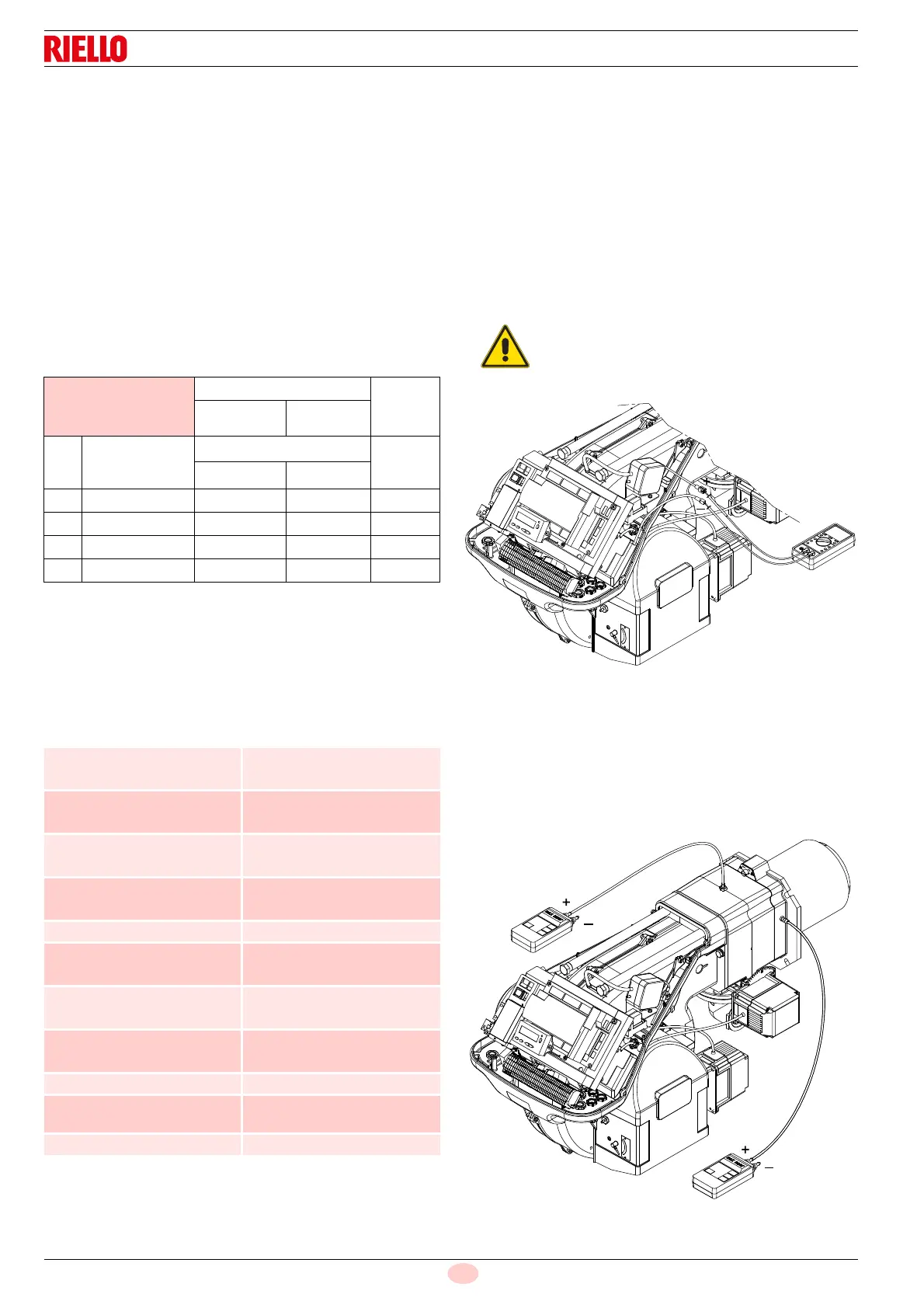

7.2.6 Checking the air and gas pressure on the

combustion head

To carry out this operation a pressure gauge must be used to

measure the air and gas pressure at the combustion head, as

shown in Fig. 38.

EN 676

Air excess

CO

Max. output

1.2

Max. output

1.3

GAS

Theoretical

max. CO

2

0 % O

2

CO

2

% Calibration

mg/kWh

= 1.2

= 1.3

G 20 11.7 9.7 9 100

G 25 11.5 9.5 8.8 100

G 30 14.0 11.6 10.7 100

G 31 13.7 11.4 10.5 100

Safety component Life cycle

Flame control

10 years or 250.000

operation cycles

Flame sensor

10 years or 250.000

operation cycles

Gas valves (solenoid)

10 years or 250.000

operation cycles

Pressure switches

10 years or 250.000

operation cycles

Pressure adjuster 15 years

Servomotor (electronic cam)

10 years or 250.000

operation cycles

Oil valve (solenoid)

10 years or 250.000

operation cycles

Oil regulator

10 years or 250.000

operation cycles

Pipes/ oil fittings (metallic) 10 years

Flexible hoses (if present)

5 years or 30.000

pressurised cycles

Fan impeller 10 years or 500.000 start-ups

Carefully check the polarities!

D7978

Checking

air pressure

Checking

gas pressure

Fig. 38

Loading...

Loading...