29

20068428

Installation

5.10.2 Gas train

Type-approved in accordance with EN 676 and supplied sepa-

rately from the burner.

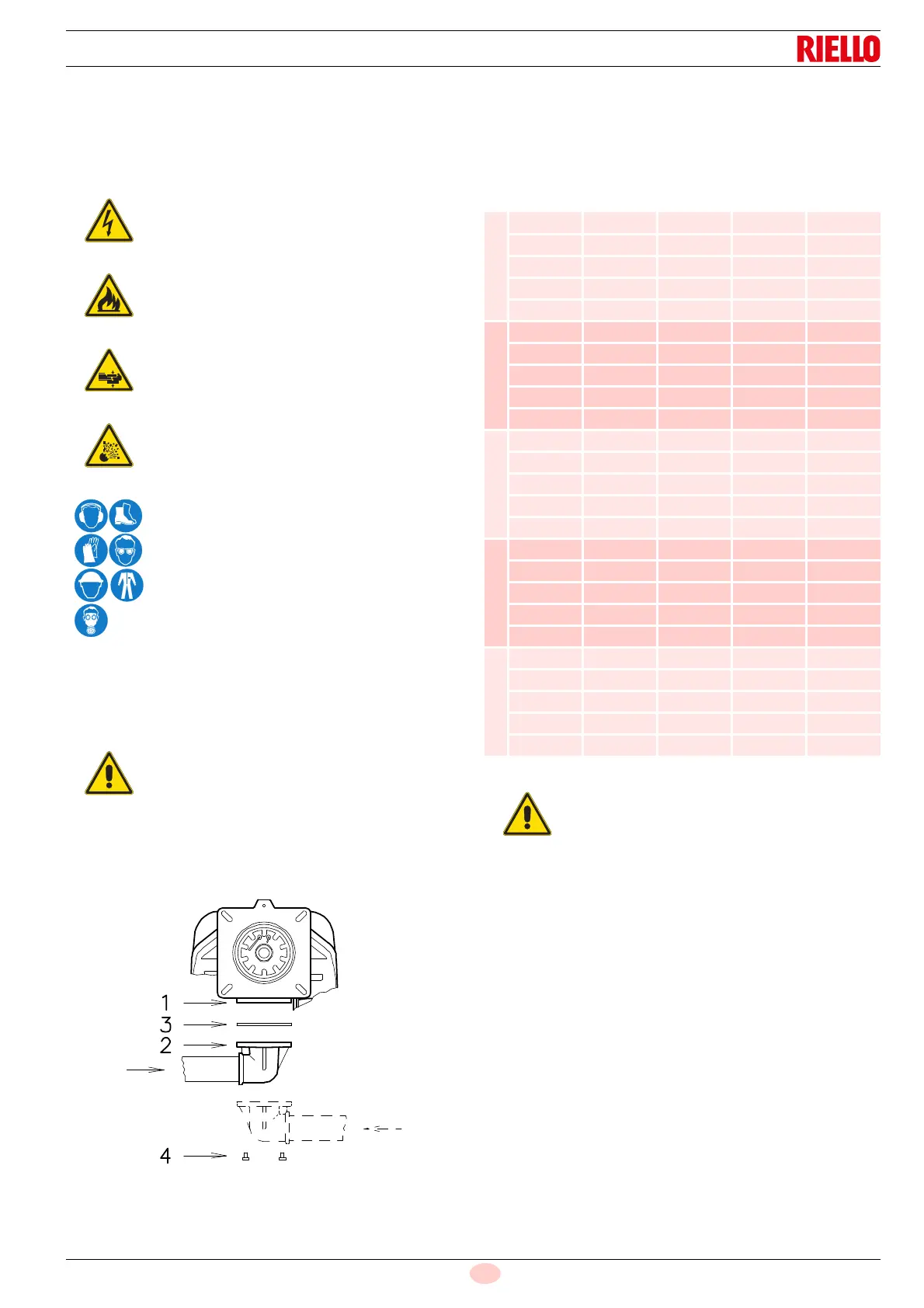

5.10.3 Gas train installation

The gas train can enter the burner from the right or left side, de-

pending on which is the most convenient, see Fig. 25.

The gas train must be connected to the gas attachment

1)(Fig. 25), with the flange 2), the gasket 3) and the screws 4)

supplied with the burner.

See the accompanying instructions for the adjustment of the gas

train.

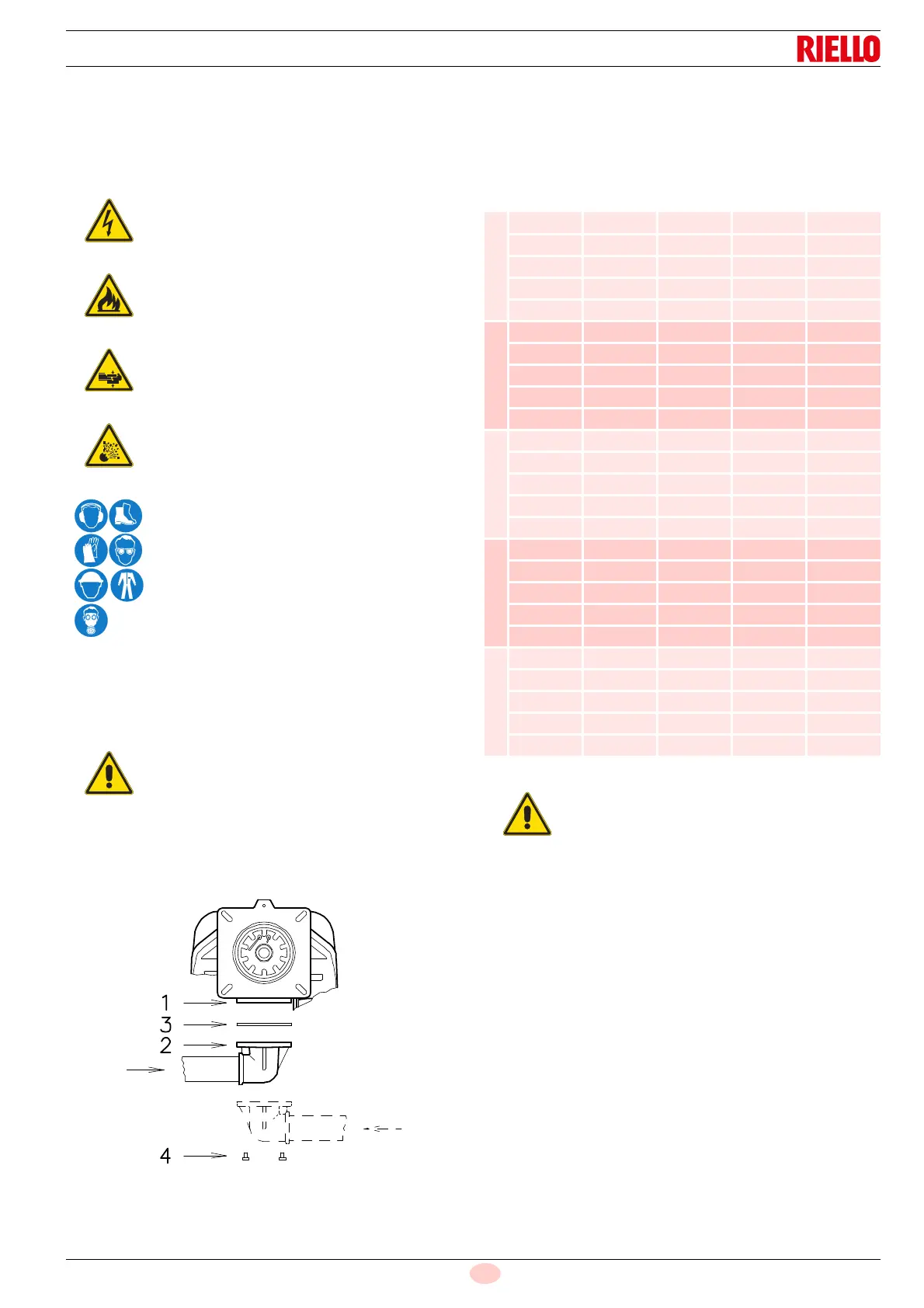

5.10.4 Gas pressure

Tab. O indicates the pressure drop of the combustion head and

the gas butterfly valve depending on the operating output of the

burner.

Tab. O

The values shown in Tab. O refer to:

– Natural gas G 20 NCV 9.45 kWh/Sm

3

(8.2 Mcal/Sm

3

)

– Natural gas G 25 NCV 8.13 kWh/Sm

3

(7.0 Mcal/Sm

3

)

Disconnect the electrical power using the main

system switch.

Check that there are no gas leaks.

Beware of train movements: danger of crushing of

limbs.

Make sure that the gas train is properly installed

by checking for any fuel leaks.

The operator must use appropriate tools for instal-

lation.

The gas solenoids must be as close as possible to

the burner, to ensure that the gas reaches the

combustion head within the safety time of 3s.

Ensure that the maximum pressure to the burner

is within the calibration range of the pressure reg-

ulator.

kW

1 p (mbar) 2 p (mbar)

G 20 G 25 G 20 G 25

RS 70/E

470 4.2 6.3 0.4 0.6

550 5.3 7.9 0.6 0.9

650 6.7 10.0 0.8 1.2

850 10.8 16.1 1.3 2.0

930 12.9 19.2 1.6 2.4

RS 100/E

700 3.1 4.6 0.7 1.1

800 4.3 6.4 0.9 1.4

1000 6.8 10.1 1.3 2.0

1200 9.1 13.6 1.9 2.8

1340 11.4 17.0 2.4 3.6

RS 130/E

930 4.6 6.9 0.2 0.3

1090 5.8 8.7 0.6 0.8

1250 7.0 10.4 1.2 1.8

1410 8.3 12.4 1.5 2.2

1512 9.1 13.6 1.5 2.2

RS 190/E

1280 9.6 14.3 1.3 2.0

1500 9.7 14.5 1.8 2.7

1800 9.9 14.8 2.7 4.0

2100 12.6 18.8 3.6 5.4

2290 14.9 22.2 4.3 6.4

RS 250/E MZ

1250 5.2 7.8 3.0 4.4

1500 7.2 10.7 4.4 6.6

2000 11.3 16.9 7.7 11.4

2400 15.8 23.6 11.2 16.7

2650 19.4 28.9 13.6 20.3

The heat output and gas pressure data in the

head refer to operation with gas butterfly valve

fully open (90°).

Loading...

Loading...