2.4 Place of installation

R RTQ steel boilers must be installed in a dedicated boiler

room, with adequately sized vents, in compliance with applica-

ble laws and standards.

If at all possible, the boiler should be installed on a raised base

to prevent the burner fan sucking up dust.

9

When installing the boiler, allow sufcient space around it

to access all safety and control devices and to permit easy

maintenance.

9

If the specic weight of the gas supply to the burner is

greater than the specic weight of air, install all electrical

parts at least 500 mm above oor level.

0

Do not install the boiler outdoors. It is not designed to work

outdoors and is not tted with the necessary automatic an-

ti-frost systems to do so.

2.5 Installation in older systems and systems

requiring modernisation

When installing these boilers in old systems or systems requiring

modernisation, always perform the following checks:

− make sure that the stack is able to withstand the tempera-

ture of the combustion gases and that it has been designed

and mad

e in compliance with applicable standards. The

stack must also be as straight as possible, sealed, insulated

and not blocked or choked;

− make sure that the electrical system has been installed by a

qualied electrician in compliance with applicable stand

-

ards;

− make sure that the oil feed line and any oil storage tank are

made and installed in compliance with applicable stand-

ards;

− make sure that the expansion vessels are big enough to

contain the volume generated by thermal expansion;

− make sure that ow rate, head and direction of ow of the

pumps are suitable and correct;

− make sure that the circuit has been ushed out to remove

all sludge and lime scale, and has been vented and seal

tested.

− make sure that a suitable water treatment system is installed

if the quality of the supply/recirculation water so demands.

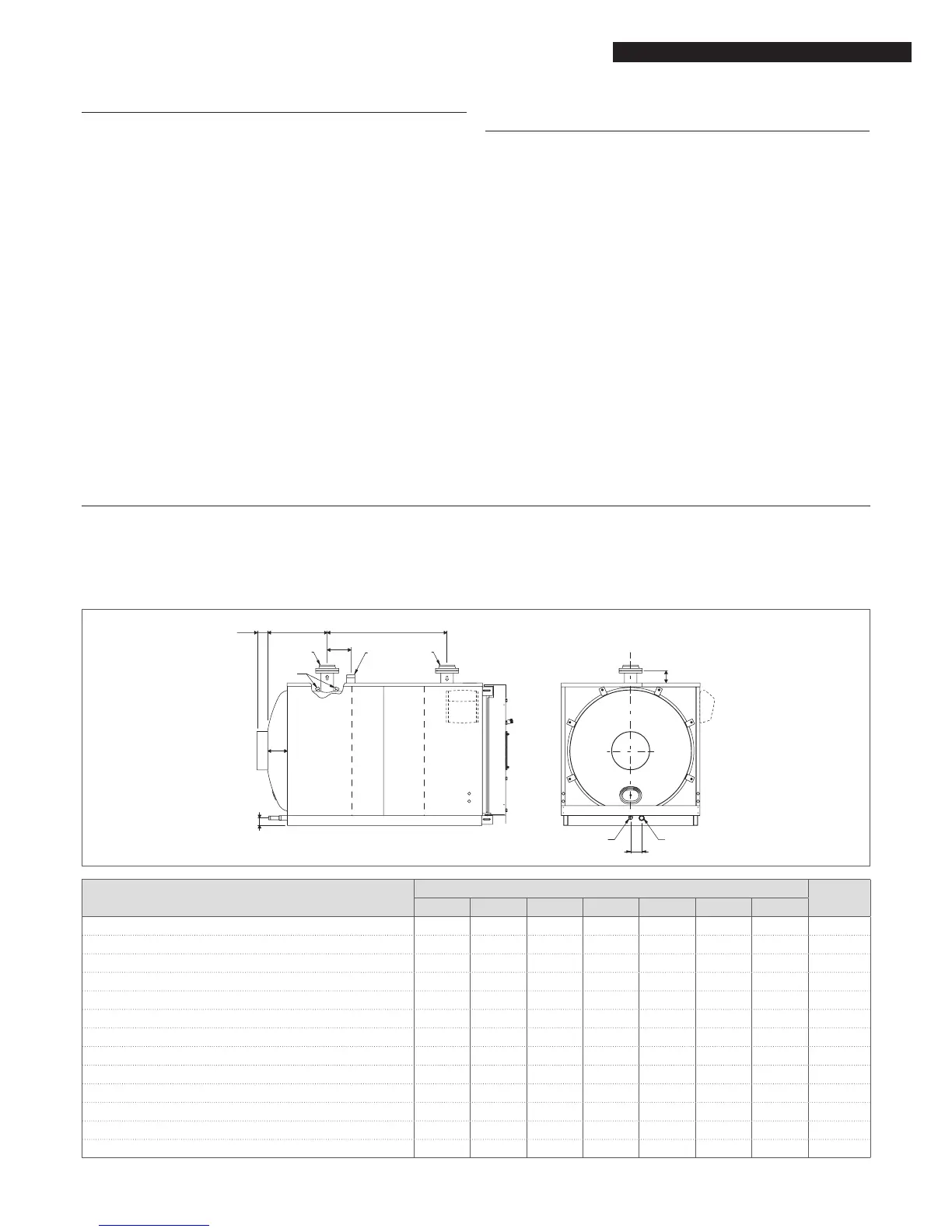

2.6 Water connections

R RTQ boilers are designed and made for use in central heating installations, but can also be used for domestic hot water pro-

duction if connected to a suitable storage cylinder. Water ttings are as specied in the following table.

9

Allow for the dimensions of the control panel that needs to be installed on top of the boiler.

G

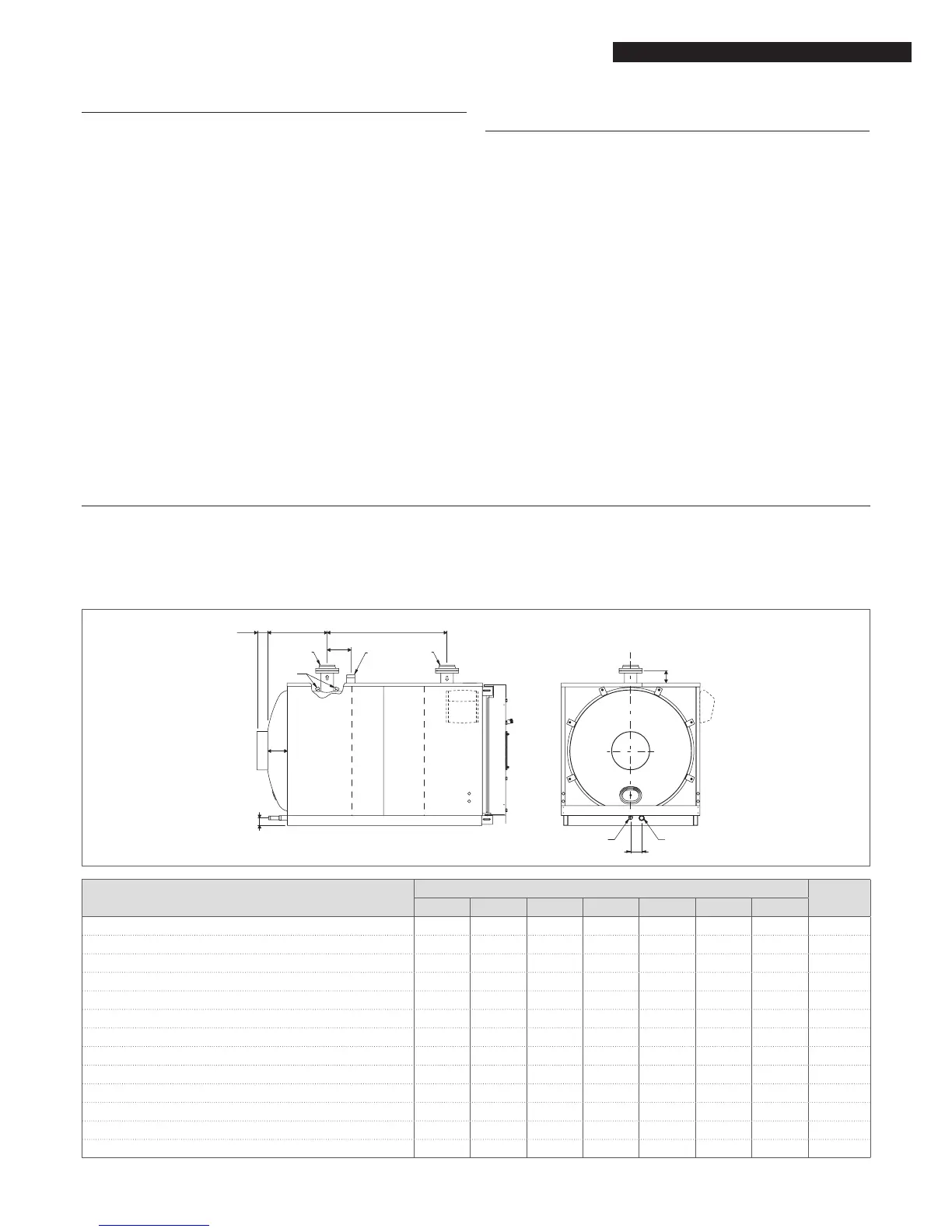

DESCRIPTION

RTQ

953 1074 1308 1500 1700 2000 2336

1 Central heating ow * DN100 DN100 DN125 DN125 DN125 DN150 DN175 Ø

2 Instrument bulb / sensor socket G1/2" G1/2" G1/2" G1/2" G1/2" G1/2" G1/2" Ø

3 Safety device tting G1"1/2 G2"1/2 G2"1/2 DN 80 DN 80 DN100 DN100 Ø

4 Central heating return * DN100 DN100 DN125 DN125 DN125 DN150 DN175 Ø

5 Condensate drain G1" G1" G1" G1" G1" G1" G1" Ø

6 Boiler drain G1"1/4 G1"1/4 G1"1/4 G1"1/2 G1"1/2 G1"1/2 G1"1/2 Ø

A 1250 1300 1600 1650 1650 1650 1910 mm

B 505 580 655 700 700 735 745 mm

C 105 105 115 125 125 142 122 mm

D 300 250 650 380 380 280 510 mm

E 110 110 110 115 115 115 120 mm

F 95 95 115 120 120 117 155 mm

G 180 125 170 180 180 215 335 mm

(*) All anged connections are PN6 according to EN 1092-1.

Loading...

Loading...