2.8 Hoses should also be xed to the oor and

suitably protected whenever possible

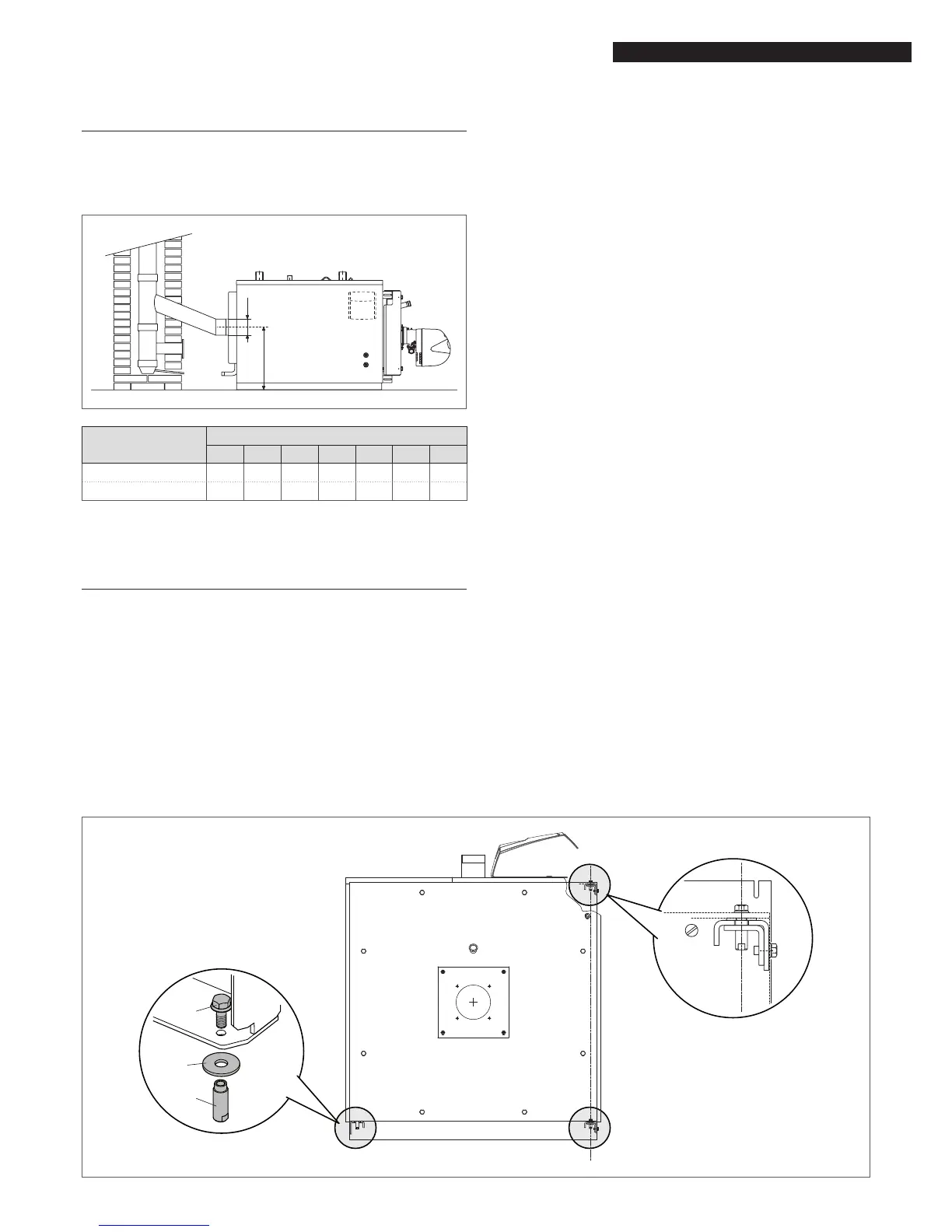

The ue gas exhaust and stack connection must be made in

compliance with applicable laws and standards, using heat re-

sistant, condensate resistant and stress resistant rigid pipe and

sealed joints.

H

0

30

6

0

9

0

Ø

RTQ

953 1074 1308 1500 1700

2000

2336

Ø (mm) 300 350 400 450 450 500 500

H (mm) 690 715 820 865 865 900 1000

9

The stack must guarantee the minimum draught specied

by applicable technical standards, assuming zero pressure

at the connection to the ue gas exhaust. Draught at the

stack must not exceed 0.2 mbar. Fit a draught limiter if

draught exceeds this value.

9

Inadequate or badly dimensioned stacks and exhausts can

increase combustion noise, cause condensation problems

and affect combustion parameters.

9

Uninsulated ues are potentially dangerous and can cause

burns.

9

Joints must be sealed using materials capable of withstand-

ing temperatures of at least 200°C (e.g. ller, mastic or sili-

cone based sealant).

9

The connection between the horizontal section of ue and

the vertical stack must be either straight or at an angle of no

more than 45°.

9

If more than one boiler is installed in the same utility room,

separate ues must be provided for each boiler. If this is not

possible, the burners should denitely be equipped with

automatic closing of the air damper.

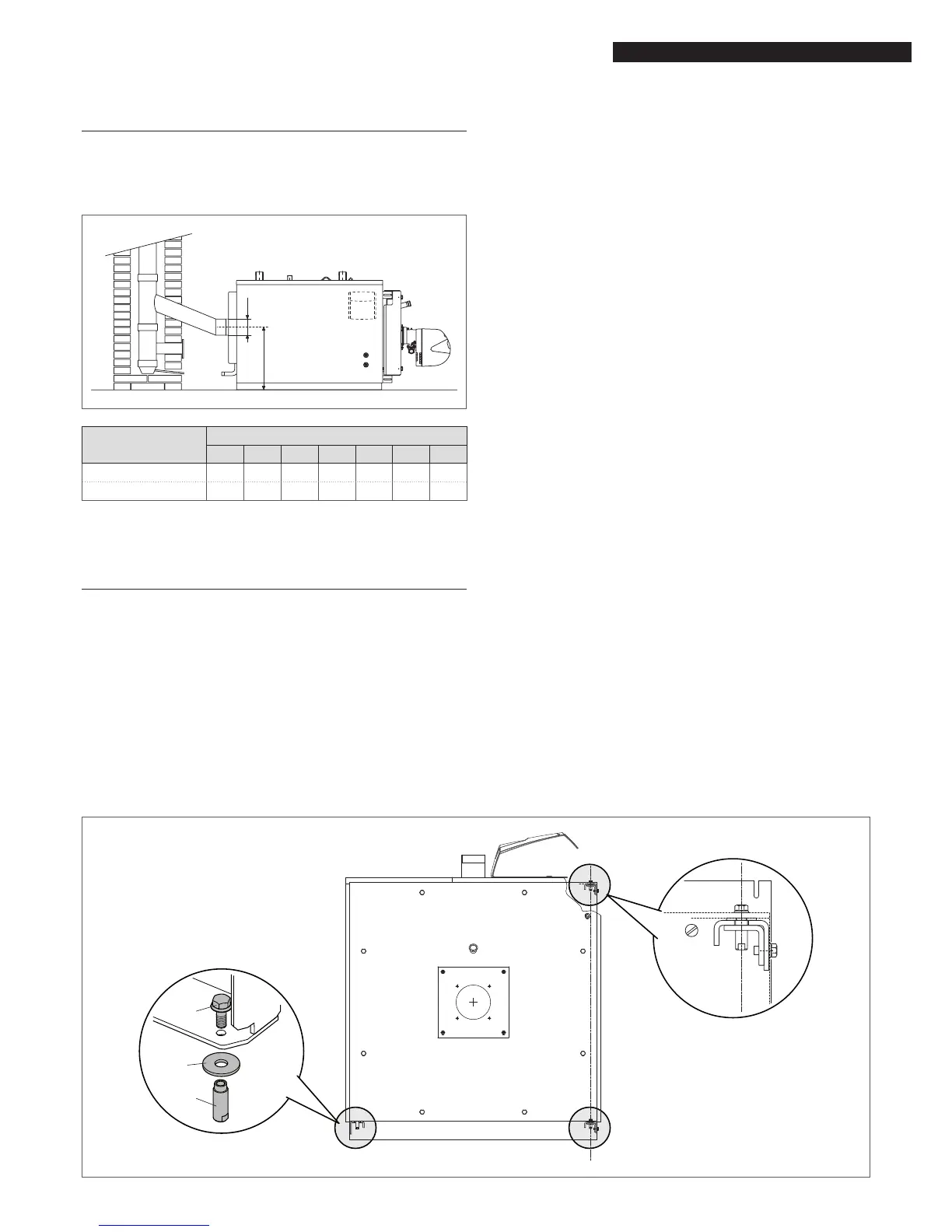

2.9 Door hinges

Boilers are tted with three door hinge points in the factory.

The doors are initially tted to open to the right. If you need to

change the door to open to the left, make the necessary modi-

cations before performing any tests that require the boiler door

to be opened. Proceed as instructed below to change the direc-

tion of door opening.

9

Once you have decided on the direction of door opening

and the door opens successfully, remove the unused hinge

assembly B.

Axis of door

rotation

A

A

B

1

2

3

Loading...

Loading...