9

Make sure that the door is properly adjusted after every

maintenance operation.

ADJUSTING THE DOOR

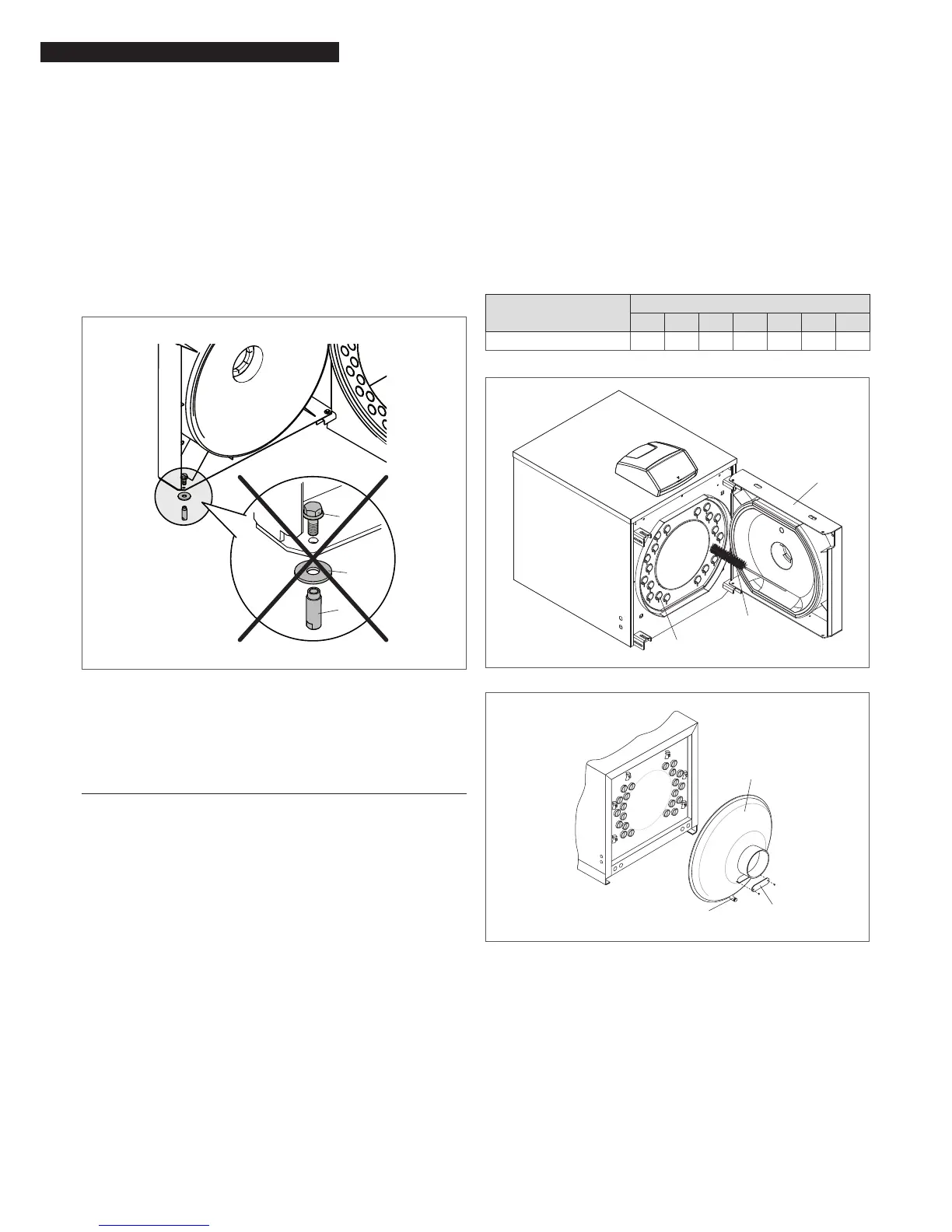

Make quite sure that the door presses uniformly all around the

double seal to prevent dangerous fumes escaping into the air

from the pressurised furnace. Proceed as follows to adjust the

door seals:

− push the door shut and tighten the main xing bolts (1)

until the seals start to compress;

− loosen the safety bolts (2 and 3) then fully tighten the

main door xing bolts (1);

− re-tighten the safety bolts (2 and 3).

9

11

10

B

9

The rst time you open the door, remove the spare hinge

assembly ‘B’ [bushing (10), bolt (9), and washer (11)] oppo-

site the hinged side of the door.

2.18 Cleaning the boiler

Clean the boiler and remove any carbon deposits from the sur-

faces of the heat exchanger at least once a year. This not only

extends the boiler’s working life, but also keeps it efcient in

terms of heat output and consumption.

Proceed as follows to clean the boiler:

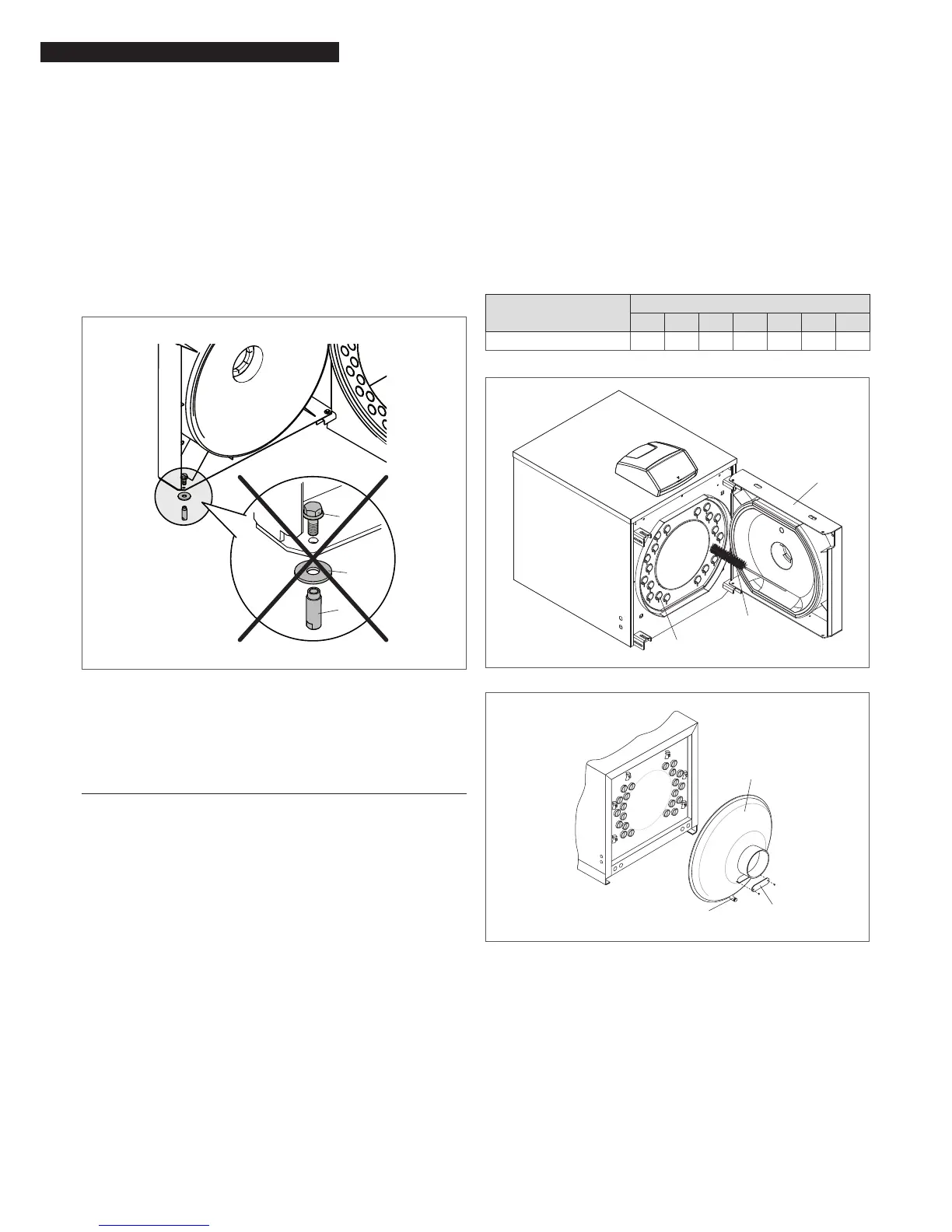

− open the front door (1) and pull out the turbulators (2);

9

If you need to replace any turbulators, make sure that the

replacements have the characteristics listed in the table be-

low.

− Use a ue brush (3) or other suitable tool to clean inside

the combustion chamber and the ue gas pipes;

− open the inspection window (4) and clean out any de-

posits from inside the ue gas box.

If more thorough cleaning is required, remove the ue gas box

cover (5). Fit a new glass bre seal when tting the cover again.

Check at regular intervals that the condensate drain (6) is not

blocked.

On completion of cleaning, follow the above steps in the reverse

order to ret all removed parts.

9

When using heavy oil fuels (e.g. naphtha, etc.) clean/service

the boiler more frequently and periodically check:

− clean the boiler’s heat exchange surfaces;

− check and clean the turbulators. Replace if worn or dam-

aged.

RTQ

953

1074

1308 1500

1700

2000

2336

N° turbulators 66 76 70 75 75 93 114

1

Loading...

Loading...