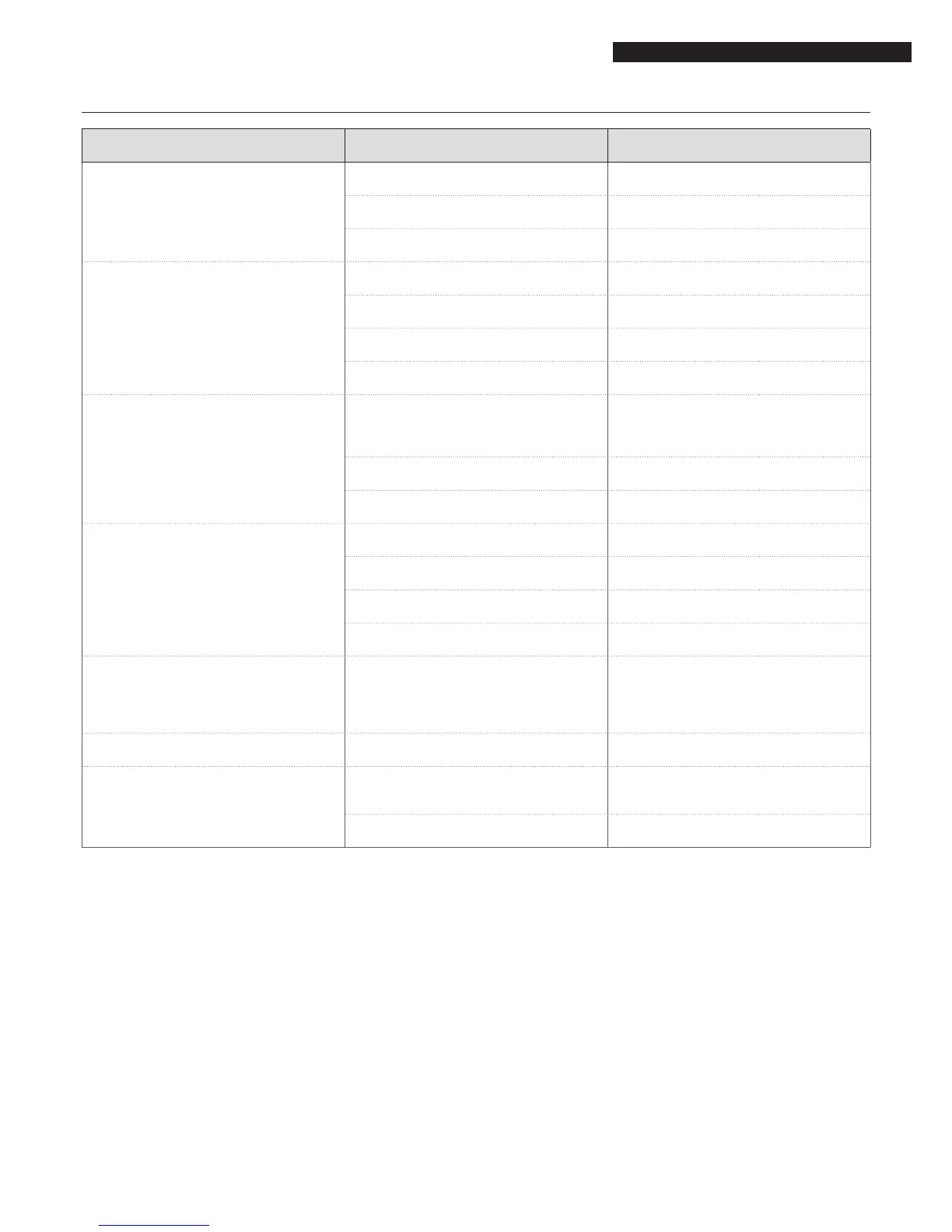

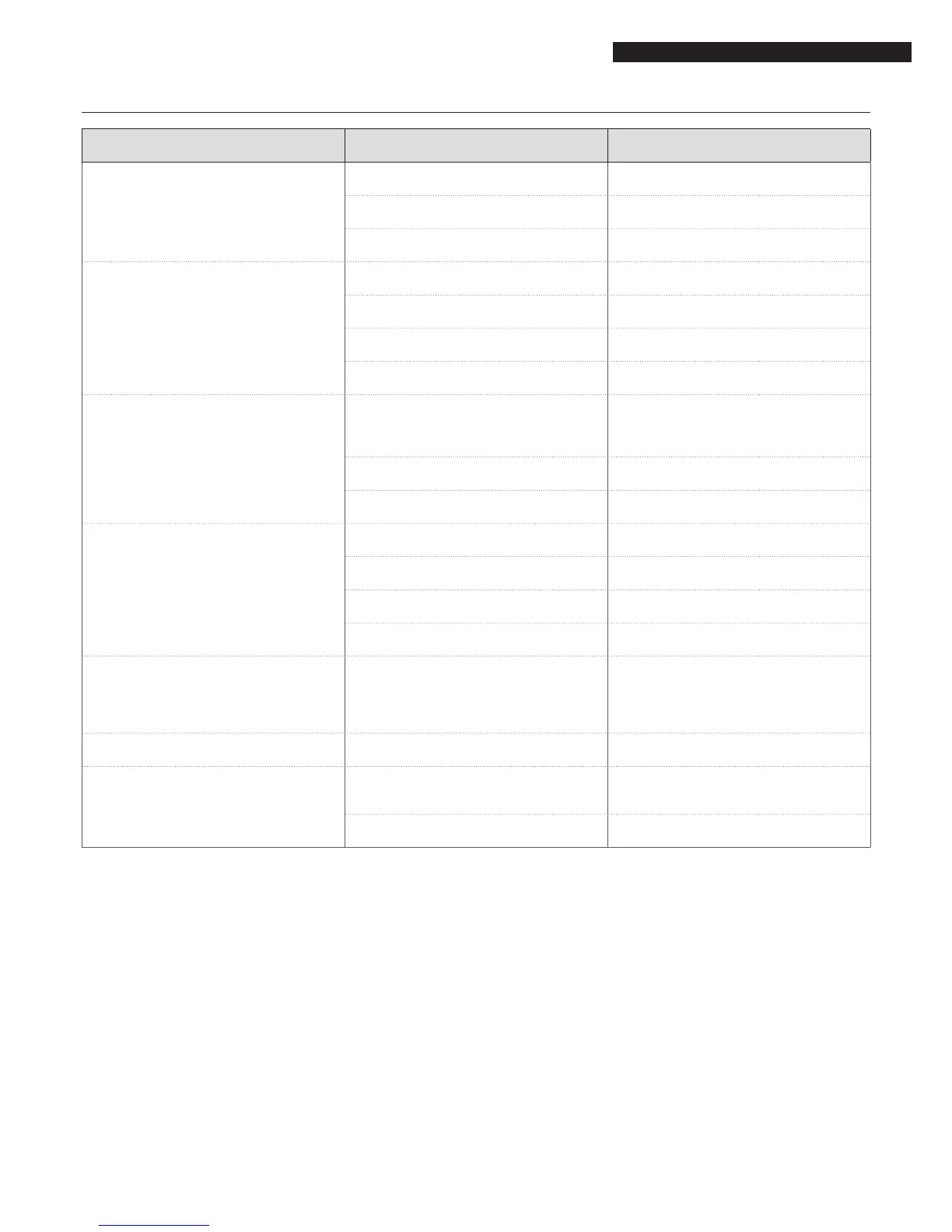

2.19 Troubleshooting

FAULT CAUSE SOLUTION

The boiler becomes dirty very quickly

Burner badly adjusted

− Check the adjustment of the burner

(perform ue gas analysis)

Blockage in stack − Clean the ue gas pipes and stack

Burner air intake dirty − Clean the burner air intake

The boiler does not reach its tempera-

ture setpoint

Boiler dirty − Clean the ue gas pipes

Boiler and burner mismatched − Check specications and settings

Insufcient air/fuel ow to burner − Check and adjust the burner

Incorrect adjustment

− Check correct functioning

− Check the temperature setting

The boiler keeps shutting down, and the

control panel warning light comes on

Incorrect adjustment

− Check correct functioning

− Check the temperature setting

− Check the electrical wiring

− Check the sensors

No water supply − Check the circuit pressure

Air in the circuit

− Check the circuit pressure

− Check the vent valve

The boiler has reached the set tempera-

ture but the radiators are still cold

Air in the circuit − Bleed the circuit

Pump malfunctioning − Check/unseize the pump

Problem with minimum temperature

thermostat (if present)

− Check the temperature setting

Problem with minimum temp. thermo-

stat (if present)

− Check the efciency of the expansion

vessel

There is a smell of fumes Fumes escaping into the air

− Clean the boiler body

− Clean the ue gas pipes

− Check that the boiler, ue gas pipes

and stack are all properly sealed

− Check the door seal

There is a smell of gas Gas supply circuit.

− Check the seals, possible blockages and

fuel quality.

The safety valve keeps opening

Circuit pressure too high

− Check the circuit pressure

− Check pressure reducer functioning

− Check pressure reducer setting

Problem with heating system expansion

vessel

− Check the efciency of the expansion

vessel

Loading...

Loading...