IMPORTANT NOTES FOR BURNER INSTALLATION

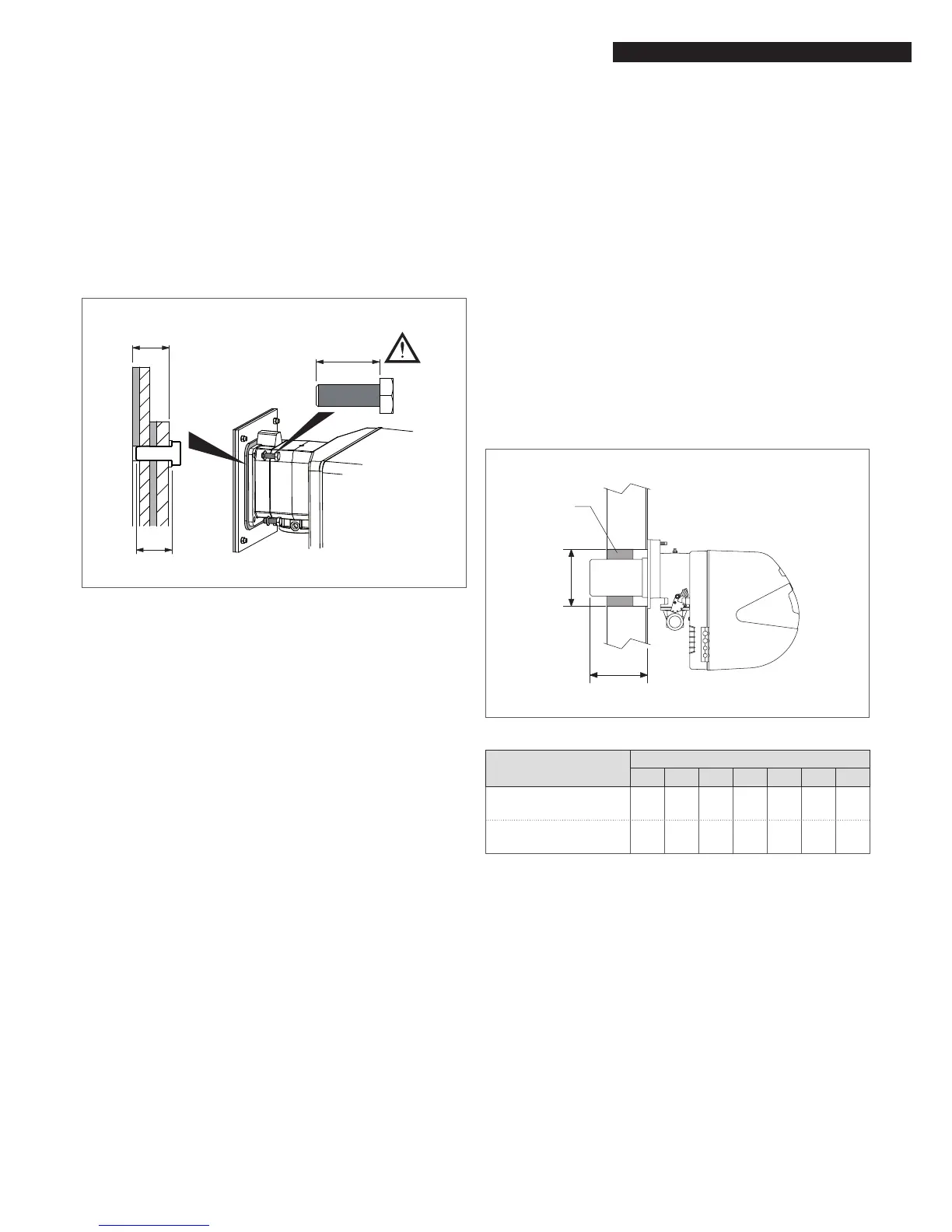

Before xing the burner to the boiler, make sure that:

− The door opens the right way (see the relevant sections

for details on how to reverse the door)

− The length (L) of the burner xing bolts is less than (S),

i.e. the total depth of the seal, plates and washer. Longer

bolts can cause the door to warp, compromising its

ability to seal the boiler hermetically and permitting

the release of combustion fumes.

To ensure correct burner installation, also refer to the burner’s

own manual.

L < S

L

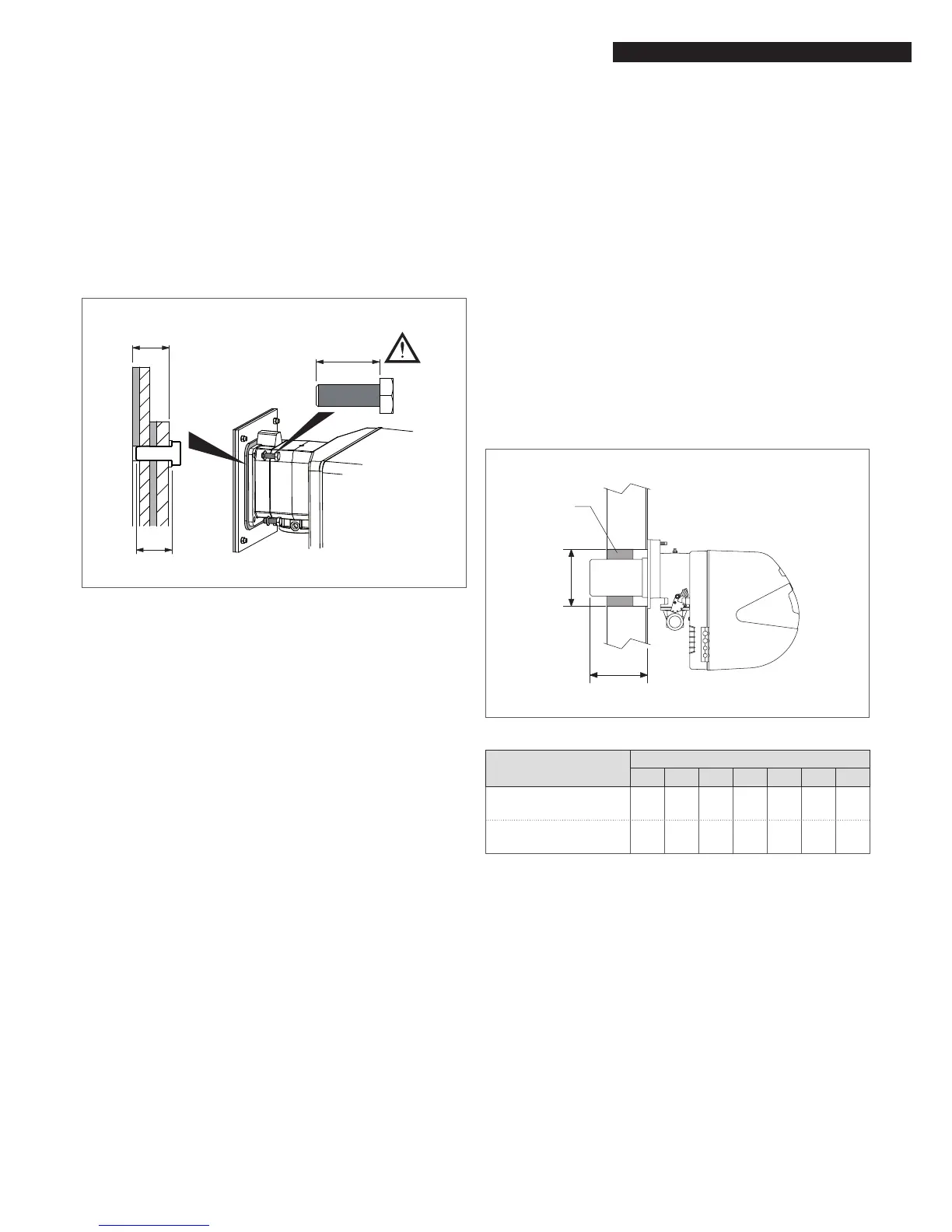

If you are installing a new boiler but re-using an old burner,

always perform the following checks:

− Make sure that the performance of the old burner is ad-

equate for the requirements of the boiler

− Make sure that the length and diameter of the burner

nozzle are as specied in the following table.

9

When you nish installing the burner in the boiler, ll the

gap between the burner’s blast tube and the refractory ma-

terial in the door with the ceramic insulation (A) supplied

with the boiler.

9

Blast tubes must not exceed the specied lengths by more

than 20%.

BURNER PLATE

R RTQ boilers are equipped with burner plates with no holes.

These plates accept the recommended burners. The burner

plates must be drilled on installation according to the burner

xing holes.

A

L

RTQ

953

1074

1308 1500

1700

2000

2336

Burner head

L min. (mm)

280 320 340 365 365 375 375

Hole in door

Ø (mm)

205 260 280 300 300 350 350

0

Do not re-use old burners if their blast tube lengths are be-

low those specied in the table.

Loading...

Loading...