Malfunctions – Causes – Solutions

If a malfunction occurs, the main menu is switched to and the malfunction is displayed in display. The

malfunction is acknowledged by pressing for at least 2 seconds.

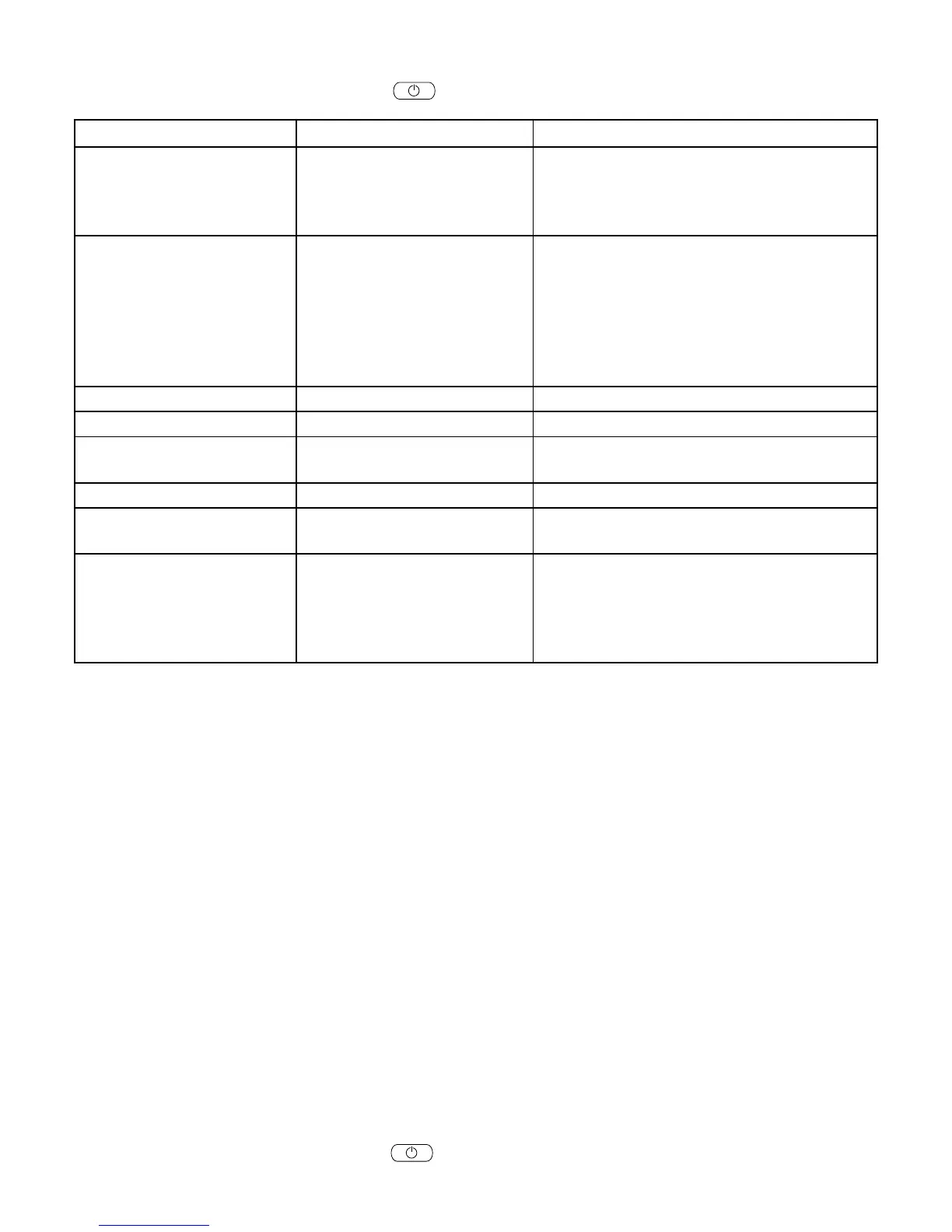

Display Malfunction designation Cause/remedy

STB >I/O<

Safety temperature limiter

is activated

Establish cause of activation; eliminate this

and reset using reset button directly at STB.

The error message must then also be

acknowledged. Only with cooled stove.

NO PELLETS >I/O< No pellets in container

May also occur on first start (first filling).

Check whether there are sufficient pellets in

the container and re-start unit after

acknowledging malfunction.

- Screw conveyor blocked

- Flame sensor sleeve dirty

- Chimney draught too great

FAN DEFECT >I/O< Flue gas blower defective Contact your local service agent.

FLAME SENSOR DEFECT >I/O< Flame sensor defective Contact your local service agent.

GRID DEFECT >I/O<

Tilting grate door motor or

tilting door contact defective

Contact your local service agent.

ROOM SENSOR >I/O< Room sensor defective Check room sensor and replace if required.

SERVICE >I/O<

Pellet amount for cleaning

and maintenance exceeded

Acknowledge the message and conduct

cleaning or maintenance procedures.

DOOR OPEN Door open

Check to make sure the door is closed and

that the door contact switch engages.

(The DOOR OPEN message doesn’t need to

be acknowledged; the display will disappear

when the door is closed.)

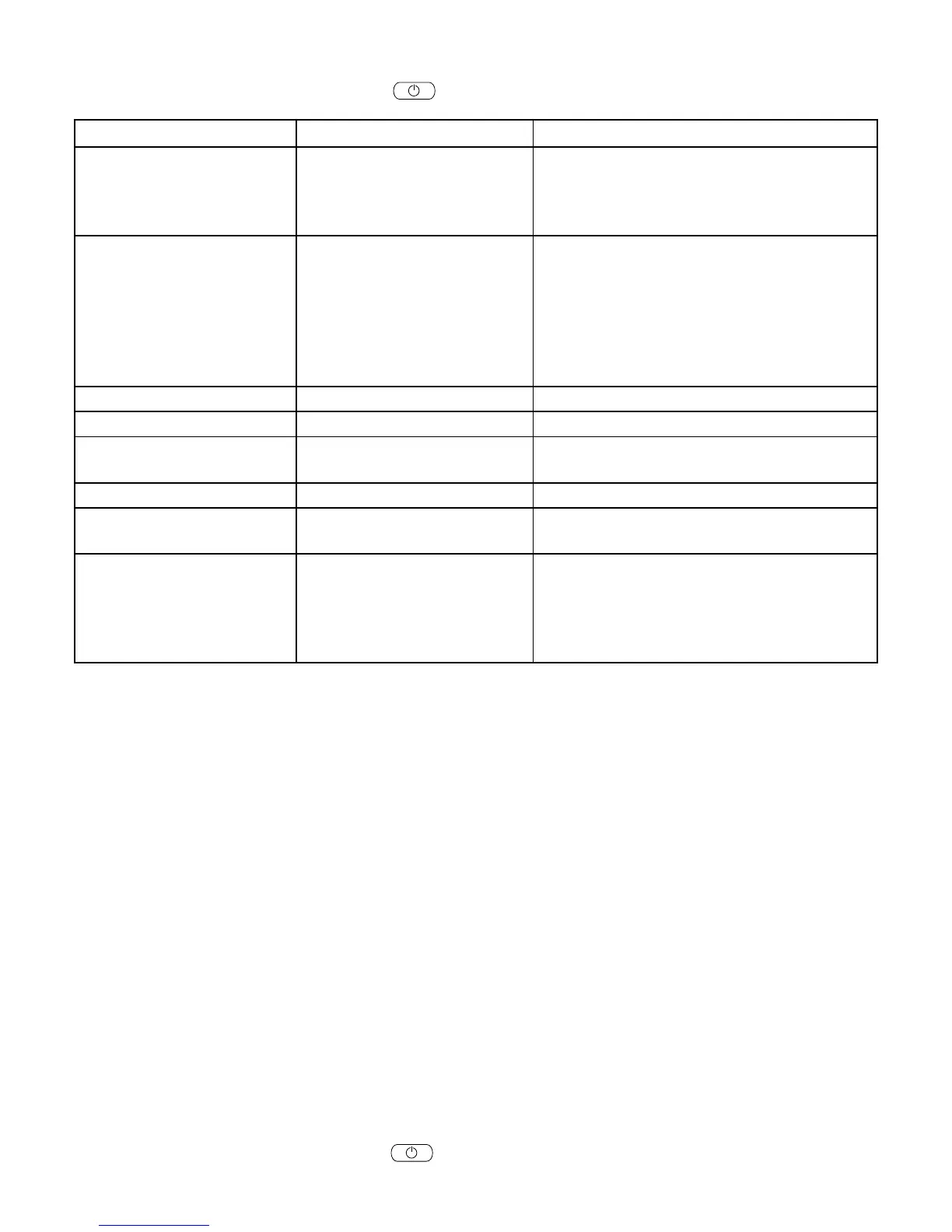

Problem

Fire burns with weak, orange flame. Pellets heap up in fire crucible, window sooted up.

Cause(s):

1. Insufficient combustion air

Possible solutions:

1. Check correct positioning of fire crucible in holder – fire crucible must be positioned tightly in the holder.

2. Remove any ash or clinker from the fire crucible that may block the air inlets, change to a better pellet

quality is possible.

3. Check whether flue gas pipes are blocked with ash (see section on “Cleaning and Maintenance”).

4. Check whether air inlet duct or flue pipe is blocked.

5. Check door seal and cleaning cover seal for leaks.

6. Clean blower wheel.

7. Have service performed by authorised specialist company.

Please note that checks on the control system and wiring may only be performed with the stove turned off.

Any repairs may only be performed by trained specialists.

If a malfunction message occurs, the cause must first be remedied; the unit can be put back into operation

by acknowledging the malfunction using .

Loading...

Loading...