33

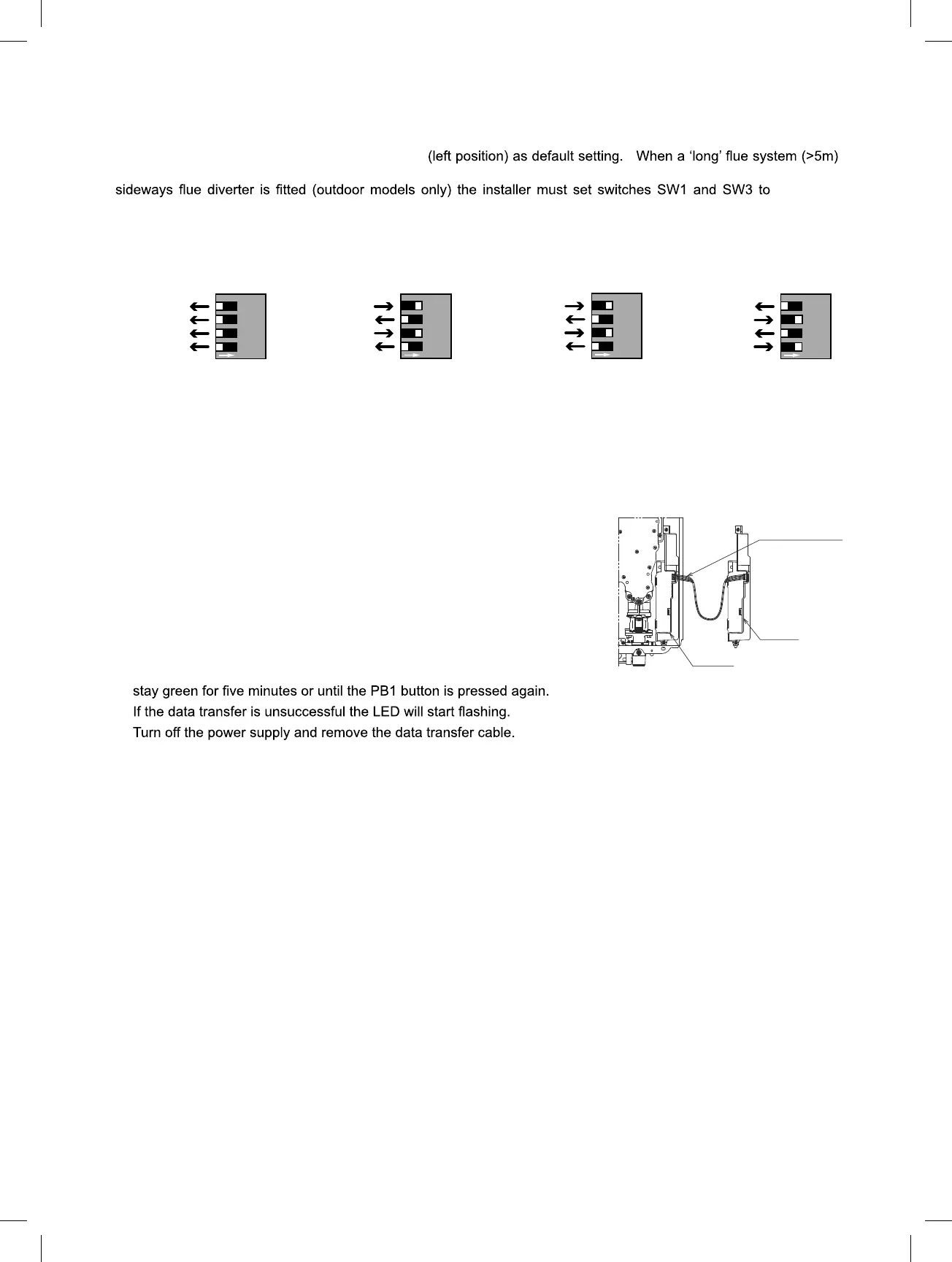

SW1 (OFF)

SW2 (OFF)

SW3 (OFF)

SW4 (OFF)

1234

DipSW

Factory default

ON

SW1 (OFF)

SW2 (ON )

SW3 (OFF)

SW4 (ON )

ON

1234

DipSW

High altitude

(>900m)

SW1 (ON)

SW2 (OFF)

SW3 (ON)

SW4 (OFF)

1234

DipSW

Flue-diverter

ON

(Outdoor model only)

SW1 (ON)

SW2 (OFF)

SW3 (ON)

SW4 (OFF)

1234

DipSW

‘Long’ flue system

ON

(Indoor model only)

Dip switch SW(4p) settings

The switches of the control board are set to OFF

is connected (indoor models only) the installer must set switches SW1 and SW3 to ON (right position). When a

ON (right

position). When the appliance is installed in high altitude areas (>900m; <1800m) the installer must set switches SW2

and SW4 to ON (right position).

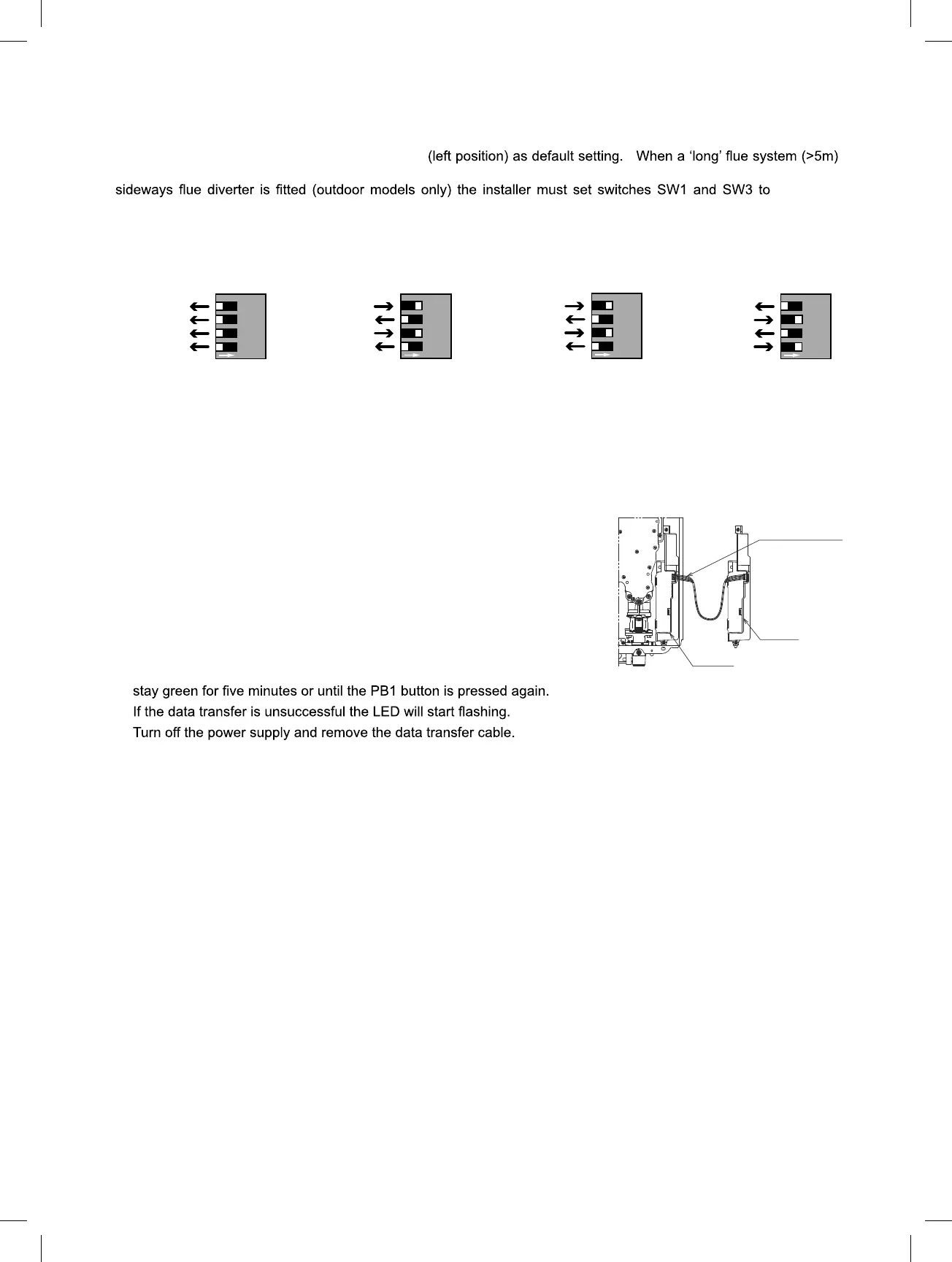

Data Transfer Between PCB’s

If a new PCB needs replacing, you can transfer data (gas type, model type, gas

pressure and error history) from the existing PCB to the new one by doing the

following:

1. Check the current settings and note them on a piece of paper.

2. Adjust the dip switch settings on the new PCB according to the old one.

3. Unplug the power supply and remove the existing PCB.

4. Fit the new PCB and connect all the wiring harnesses

5. Ensure it is earthed correctly.

6. Connect the new board to the old board using the data transfer cable provided

with the new PCB.

7. Reconnect the power supply and push PB1 button of the new PCB.

8. The LED goes green: it means that the data transfer was successful. This will

9.

10.

If the data transfer was not successful set the PCB manually according to the settings copied at the beginning of this

procedure. If manually set, the max and min gas operating pressures must be checked. Contact Rinnai UK if any assistance

is required.

Data transfer cable

Old PCB

New PCB

Enfocus Software - Customer Support

Loading...

Loading...