Genisys Dock Leveler Owners Manual

18 Pub. No. 1185-R1 - August 2004

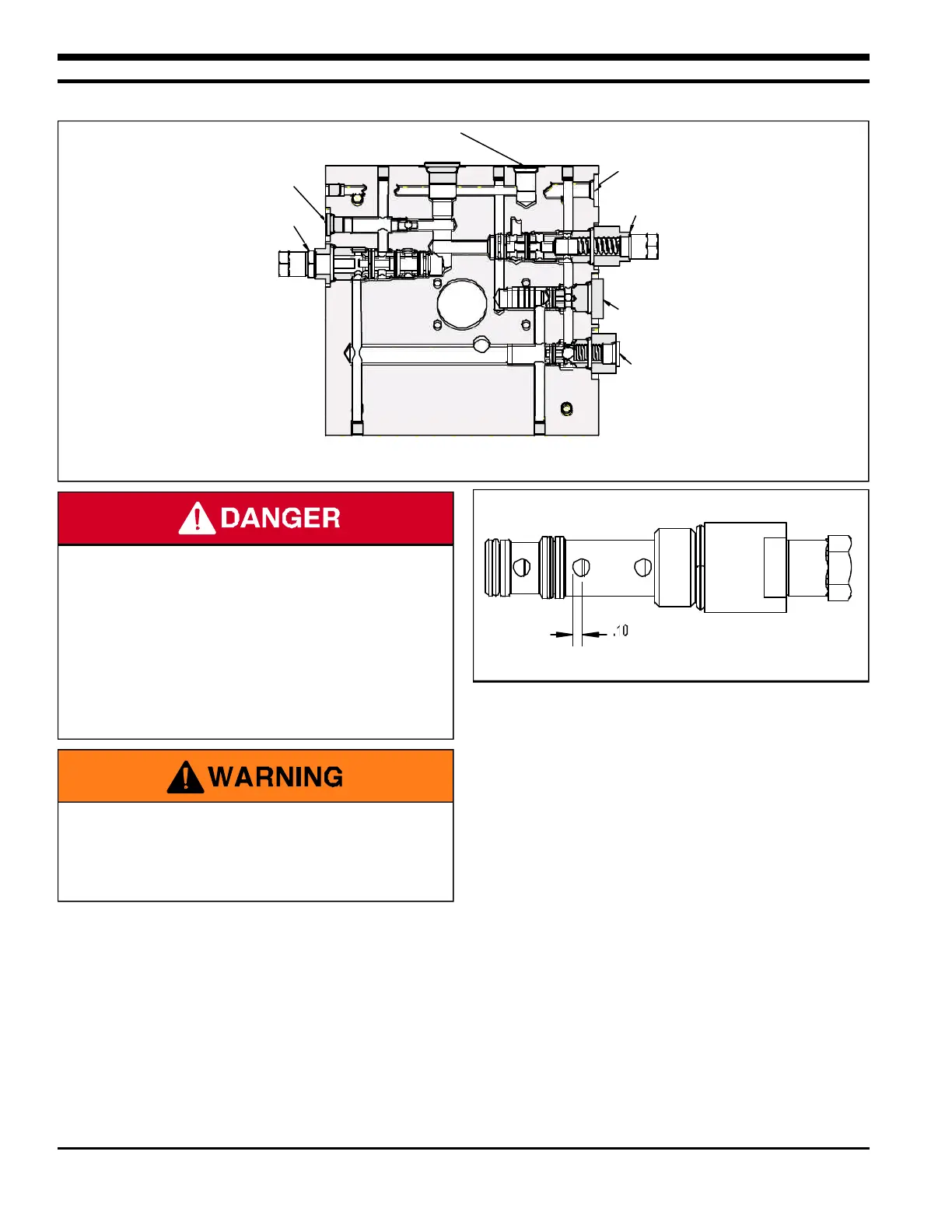

HYDRAULIC VALVE ADJUSTMENTS

SHUTTLE VALVE ADJUSTMENT

(CONTROLS LEVELER DESCENT)

Note:

• Check oil level before making any adjustments.

Note:

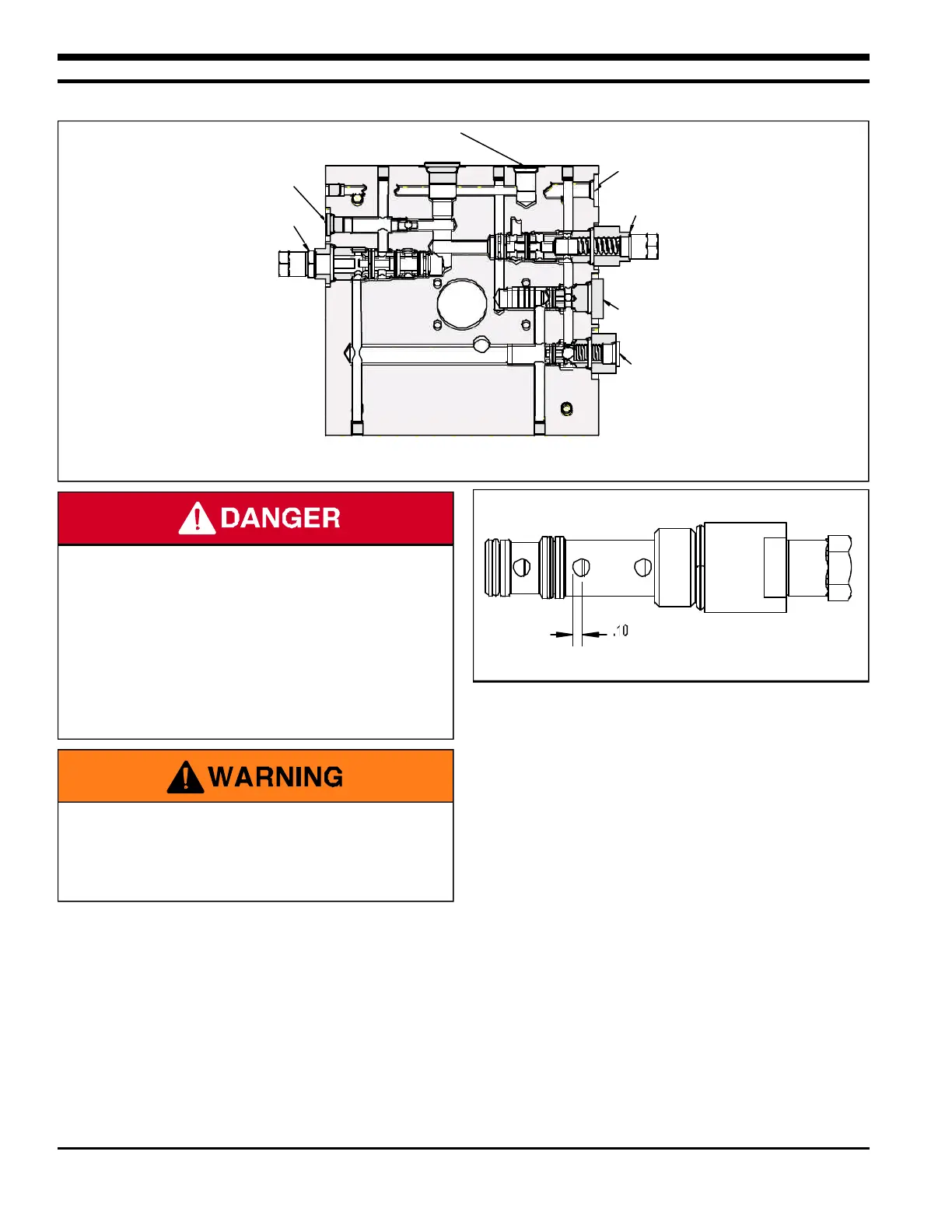

Valve Position Illustrated Represents The Nominal

Factory Setting Of 3-1/2 Turns Out From The Fully

Turned In Position

1. Leveler must be adjusted to lower, from full raised

position with lip extended to the header stops, in 8 to

12 seconds.

2. Remove protective cap and O-ring. Loosen locknut;

without turning valve body or adjustment screw. Turn

adjustment screw to vary platform lowering speed.

See Figures 20 and 21.

3. Adjustments should be no more than 1/8 turn

increments.

4. Loosen adjustment screw to decrease platform

speed while lowering (excessive loosening can

eliminate platform lowering).

5. Tighten adjustment screw to increase platform speed

while lowering (velocity fuse may lock-up as a result

of increased platform speeds while lowering).

6. Tighten locknut without turning valve body or

adjustment screw.

7. Reinstall o-ring and protective cap and tighten cap.

8. Re-test the unit several times to verify the setting.

HYDRAULIC LEVELER ADJUSTMENTS CONT.

RAMP CYLINDER PORT

LIP CYLINDER PORT

PILOT OPERATED

CHECK VALVE

ADJUSTABLE

RELIEF VALVE

ADJUSTABLE

SEQUENCE

VALVE

ADJUSTABLE

SHUTTLE

VALVE

PILOT TO

CLOSE CHECK

VALVE

• DO NOT operate leveler with anyone standing on or

in front of the lip.

• NEVER go under the hydraulic leveler platform or lip

without installing the Maintenance Support.

• Make sure that the leveler power is locked out and

tagged out according to OSHA regulations and

approved local codes.

Figure 21 - Shuttle Valve Nominal Setting

Figure 20 - Power Unit End Head

• Shuttle valve is factory adjusted and sealed.

• Adjustments to be completed by trained technician

only.

Loading...

Loading...