5-4-3

PISTON and

PISTON

RING

1) If

no

ring expander is available, install the rings by placing the open ring ends over

the

first land of the

piston and spreading the rings only far enough to slip them over the correct ring grooves.

Note:

Pay

attention not to break the rings by twisting. Install the oil ring first followed by the second

ring and then top ring. Meantime, the surfaces of the second ring and the top ring with carved

carved marks are to be faced up.

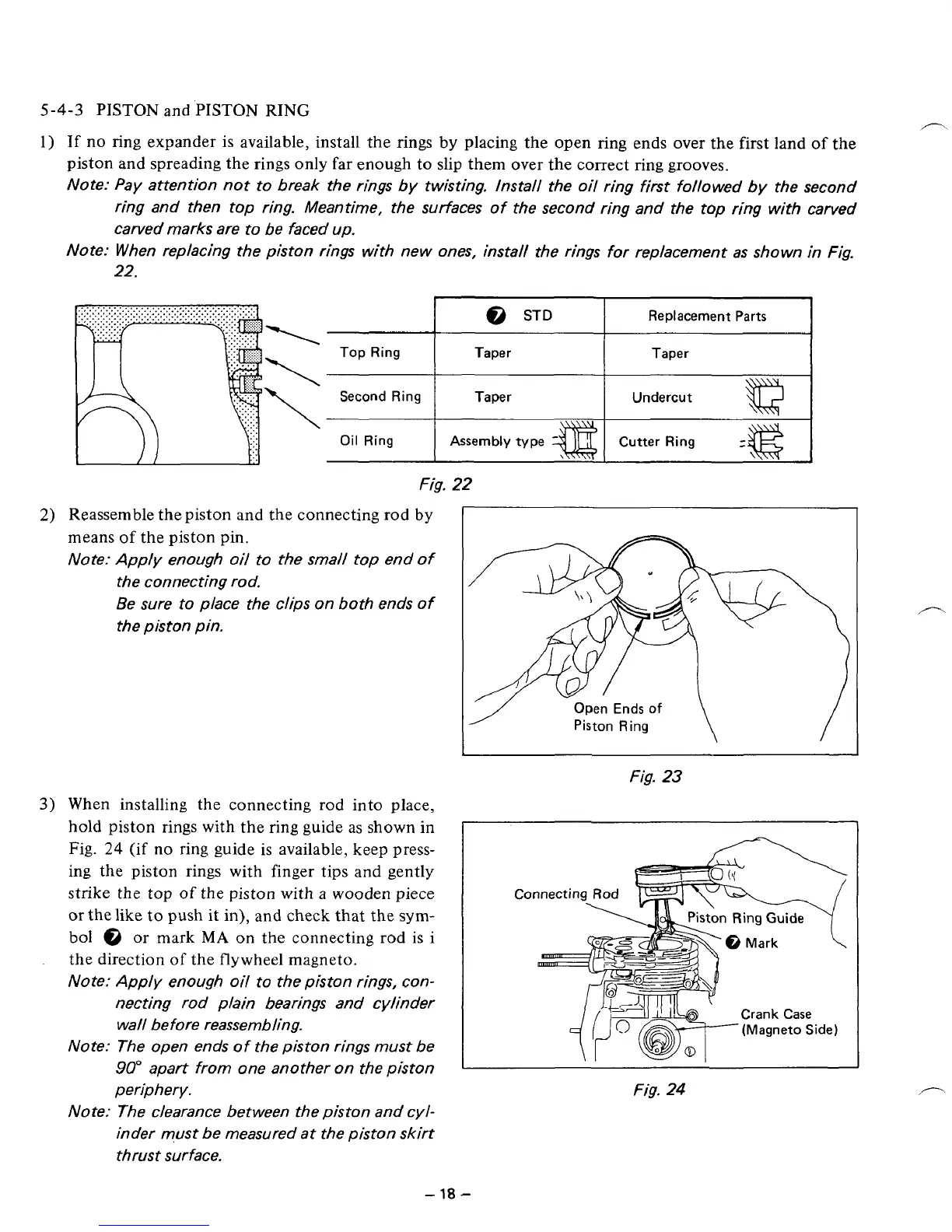

Note: When replacing the piston rings with new ones, install the rings

for

replacement

as

shown in Fig.

22.

n

I

@

STD

I

Replacement Parts

I

Top Ring Taper

I

I

Taper

Second Ring

Taper

Undercut

Ql

Oil

Ring

Cutter Ring

Assembly type

a

Fig.

22

2)

Reassemble the piston and the connecting rod by

means of the piston pin.

Note: Apply enough oil to the

small

top end of

the connecting rod.

Be sure to place the clips on both ends of

the piston pin.

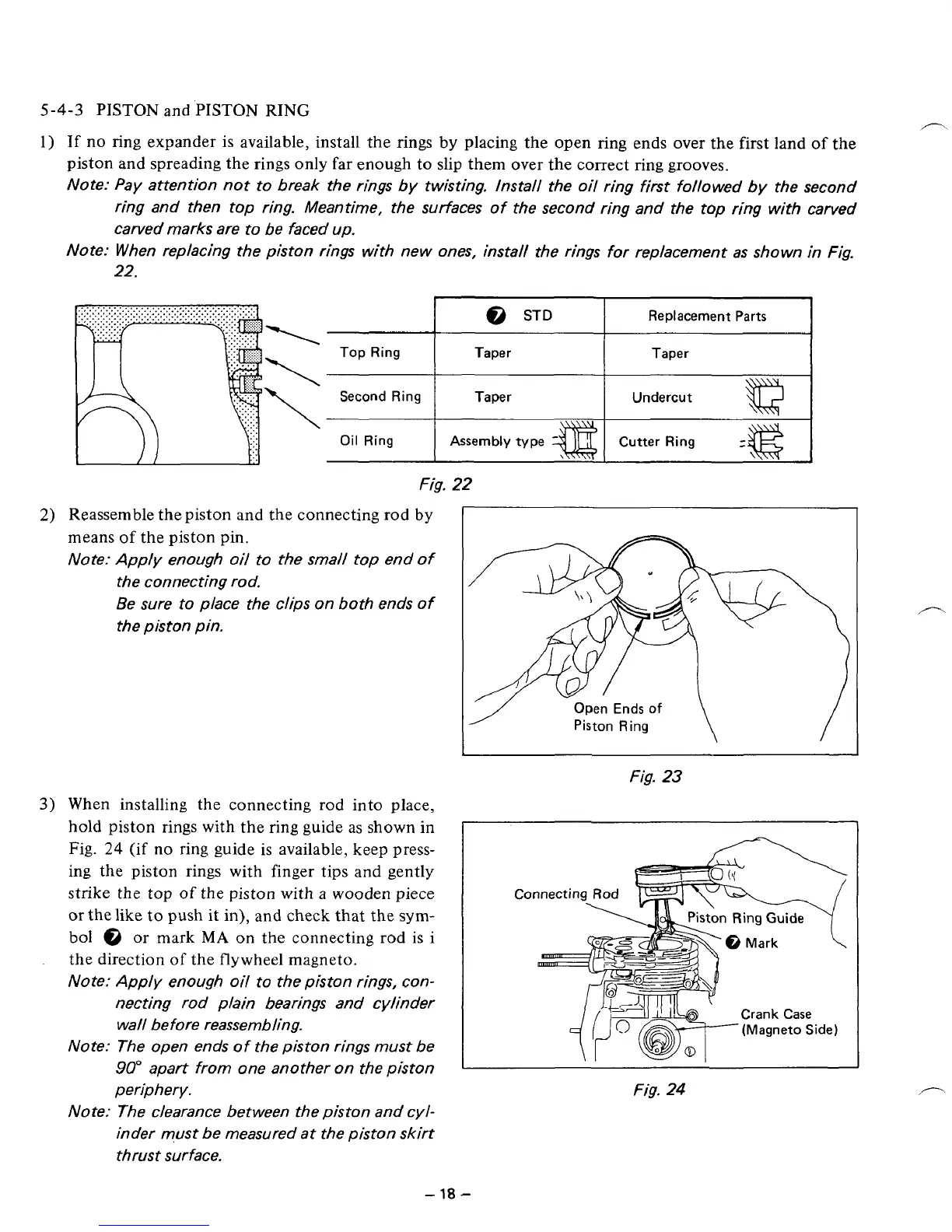

3)

When installing the connecting rod into place,

hold piston rings with the ring guide

as

shown in

Fig.

24

(if

no ring guide

is

available, keep press-

ing the piston rings with finger tips and gently

strike the top

of

the piston with a wooden piece

or the like

to

push

it

in), and check that the sym-

bol

@

or mark

MA

on the connecting rod

is

i

the direction

of

the flywheel magneto.

Note: Apply enough oil

to

the piston rings, con-

necting rod plain bearings and cylinder

wall before reassembling.

Note: The open ends of the piston rings must be

90"

apart from one another on the piston

periphery.

Note: The clearance between the piston and cyl-

inder must be measured

at

the piston skirt

thrust surface.

Fig.

23

Crank Case

(Magneto Side)

Fig,

24

-

18

-

Loading...

Loading...