8-2-4

MAIN

SYSTEM

1) Remove the bolt (12) and take out float chamber body

(10).

2)

Remove the main jet (1

3)

from the body

(6).

3)

Reassembly

a) Fasten the main jet securely to the body. Otherwise the fuel may become too rich and cause engine

b) The bolt tightening torque

is

70

kg-cm.

malfunction.

8-2-5

FLOAT

SYSTEM

Pull out the float pin

(9)

and remove the

float

(8)

and needle valve

(1

7).

If

the

needle valve need be re-

placed, replace it with rubber needle.

Caution: When cleaning the jets, use neither

a

drill nor

a

wire (because of possible damage of the orifice

which will adversely affect fuel flow). Be sure to use compressed air

to

blow them clean.

When removing the needle valve and floats, gently tap the reverse side using the rod more slender than

the float pin and remove because the float pin is calked to the carburetor body.

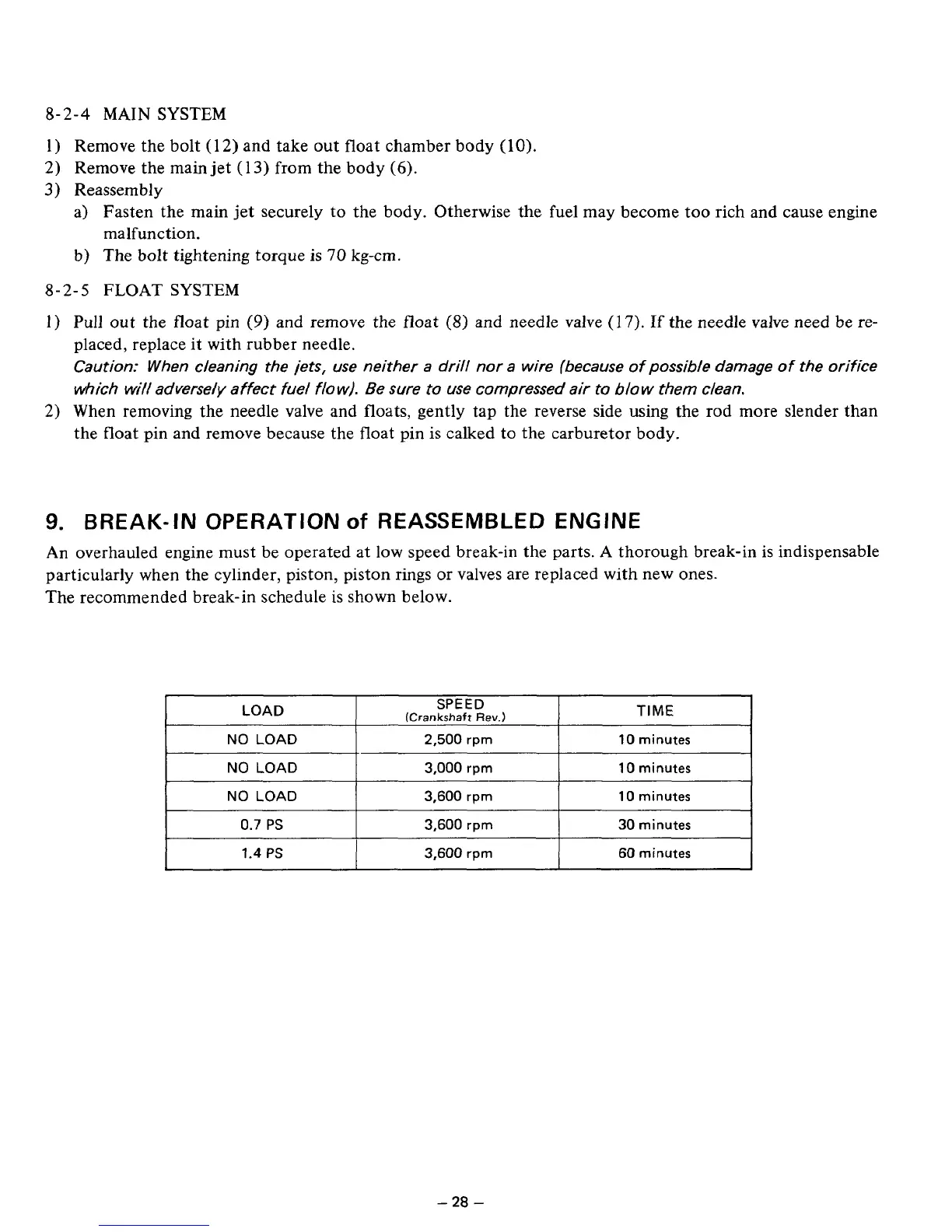

BREAK-IN OPERATION

of

REASSEMBLED ENGINE

An overhauled engine must be operated at low speed break-in the parts.

A

thorough break-in is indispensable

particularly when the cylinder, piston, piston rings or

valves

are replaced with new ones.

The recommended break-in schedule

is

shown below.

/-

I

LOAD

SPEED

(Crankshafr

Rev.)

TIME

I

2,500

rpm

10

minutes

NO

LOAD

3,000

rpm

10

minutes

NO

LOAD

30

minutes

3,600

rpm

0.7

PS

10

minutes

3,600

rpm

1.4

PS

60

minutes

3,600

rpm

-

28

-

Loading...

Loading...