-

11

-4

PRECAUTIONS

1) The oil level sensor used in this controlling system has a float which can automatically detect the oil level

according to the

oil

level change. However, if degraded oil, oil of improper grade, or oil with viscocity

which is not appropriate for the periopheral temperature should be used, sometimes the float does not

operate normally and fails in detecting the oil level.

2)

Don’t drop the

oil

level sensor and the oil level controller, nor add any physical impact to them. Don’t

pull the wire.

3)

In removing the oil level sensor from or mounting

it

to the crankcase, be careful not to damage the

O-ring. Don’t disassemble the

oil

level sensor removed.

In cleaning the

oil

level sensor, use the engine oil.

If

cleaned with gasoline or kerosene, the O-ring may

swell.

4)

Mount the oil level sensor under the condition that the crankcase has been fully cooled. Use a 21mm

spanner for tightening the bolts. Tightening torque:

80

-

90

kg-cm. (If a box spanner is used, the wire

may be damaged.) Wire connection should be done

as

shown in the wiring diagram. Be careful in tighten-

ing or wiring not to give damages to the wire.

-

5)

If

the warning lamp is broken soon, it suggest the possibility

of

the warning lamp’s capacity shortage.

Standard

Lamp

:

6V

-

0.6W

Light emitting diode:

30

mA

(ID)

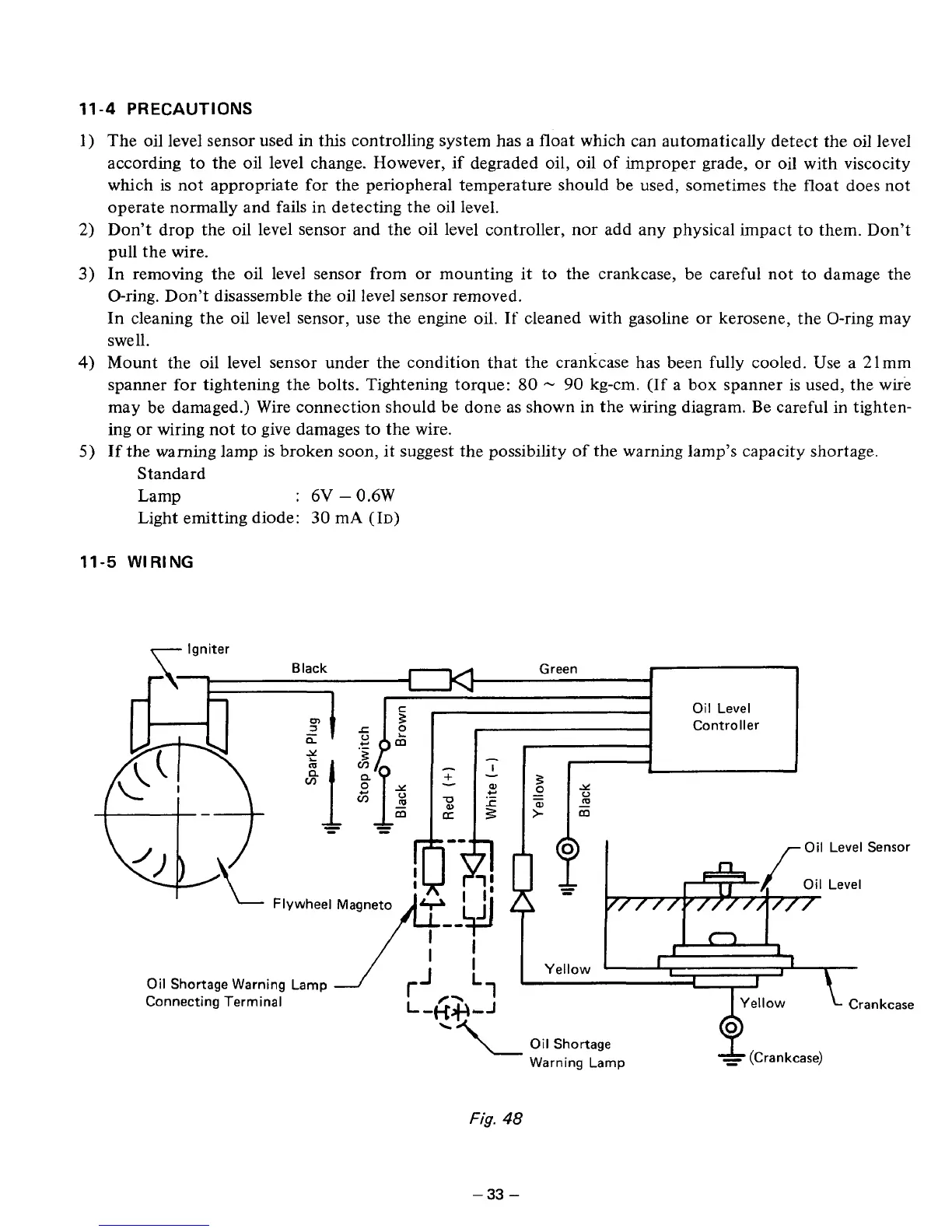

11-5

WIRING

Igniter

Green

r

E

Oil

Level

m

3

Controller

a

.-

m

-

1

4”

I

+-

.-

mZETm

m

-

-

m

-

-

-

-

-

-

0

Oil

Level Sensor

Oil

Level

Flywheel

I

1

Yellow

I

Oil

Shortage Warning Lamp

\

Connecting Terminal

#e‘1ow

Crankcase

Oil

Shortage

Warning Lamp

-

-

(Crankcase)

Fig.

48

-33

-

Loading...

Loading...