11-3

CHECKING

PROCEDURE

/-

When the engine can not be started, supply oil up to the maximum oil level, and pull the recoil keeping the

engine in the horizontal position. Engine

oil

is

supplied up till the maximum level; but it doesn't start yet,

please check the engine

in

the following manner.

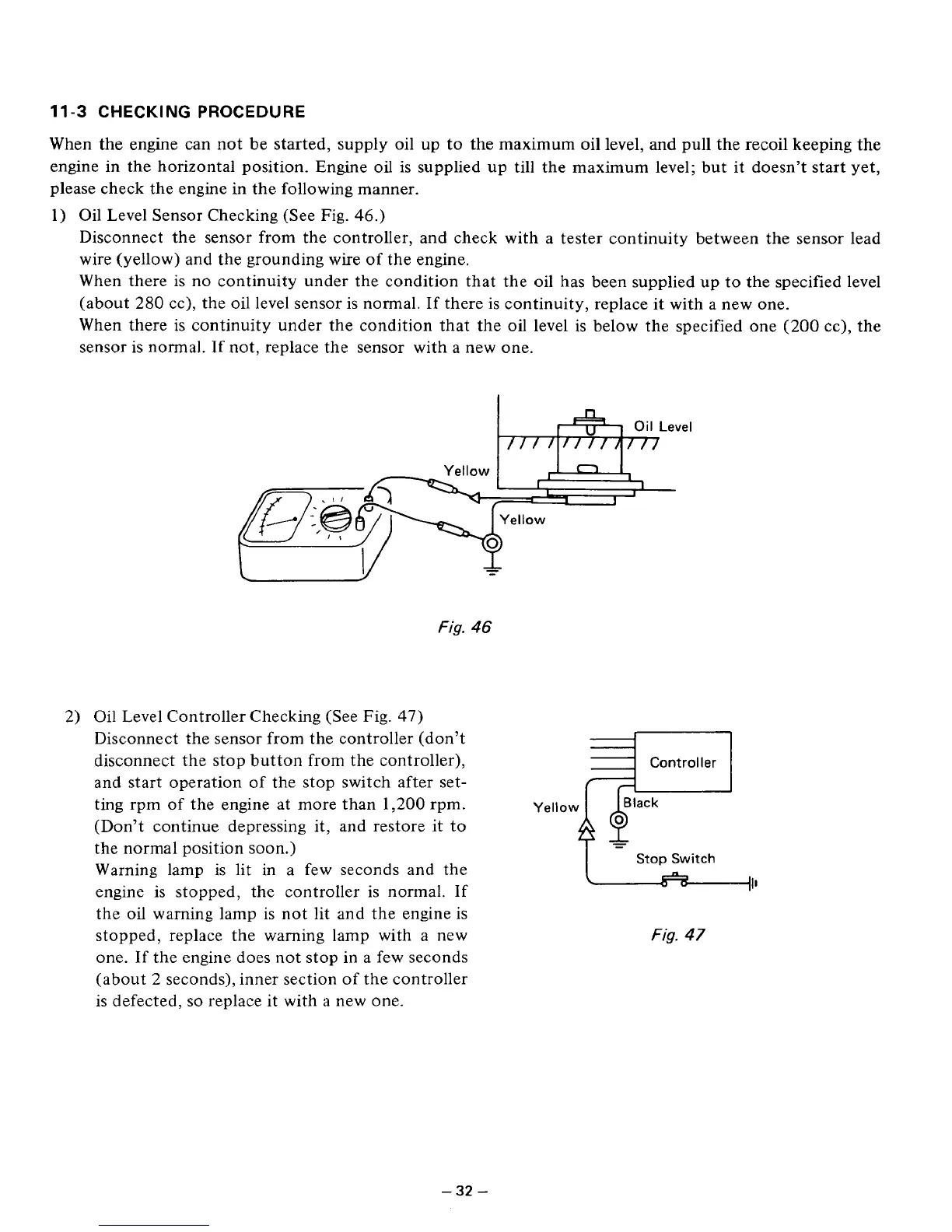

1)

Oil Level Sensor Checking (See

Fig.

46.)

Disconnect the sensor from the controller, and check with a tester continuity between the sensor lead

wire (yellow) and the grounding wire of the engine.

When there is

no

continuity under the condition that the oil has been supplied up to the specified level

(about

280

cc), the oil level sensor is normal.

If

there

is

continuity, replace it with a new one.

When there is continuity under the condition that the

oil

level is below the specified one

(200

cc), the

sensor

is

normal. If not, replace the sensor with a new one.

Fig.

46

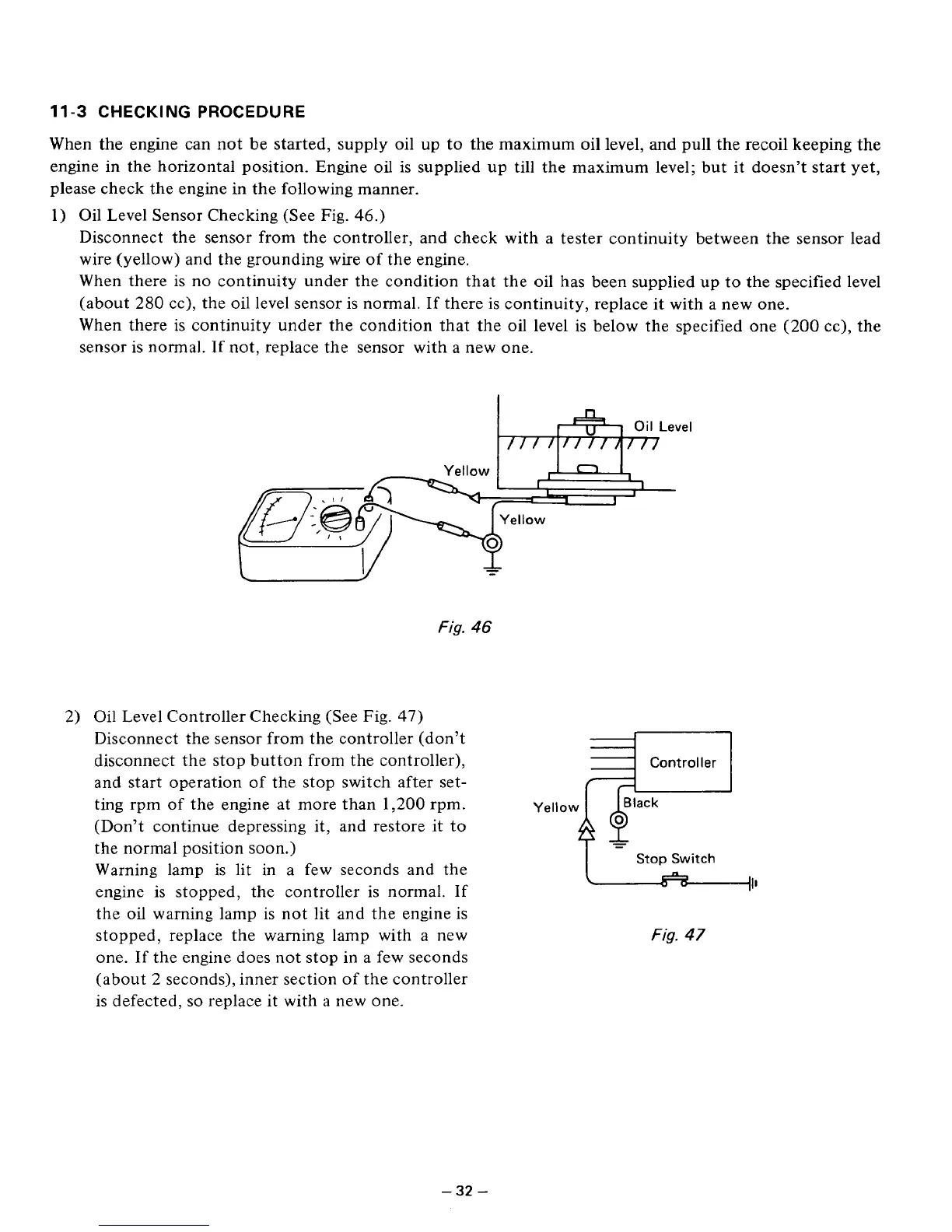

2)

Oil Level Controller Checking (See Fig.

47)

Disconnect the sensor from the controller (don't

disconnect the stop button

from

the controller),

and start operation of the stop switch after set-

ting rpm

of

the engine at more than 1,200 rpm.

(Don't continue depressing it, and restore

it

to

the normal position soon.)

Warning lamp is lit in a few seconds and the

engine is stopped, the controller is normal. If

the

oil

warning lamp is not lit and the engine is

stopped, replace the warning lamp with a new

one.

If

the engine does not stop in a few seconds

(about 2 seconds), inner section of the controller

is defected,

so

replace it with

a

new one.

Controller

Stop

Switch

111

Fig.

47

-32

-

Loading...

Loading...