16.

MAINTENANCE

and

STORING

-

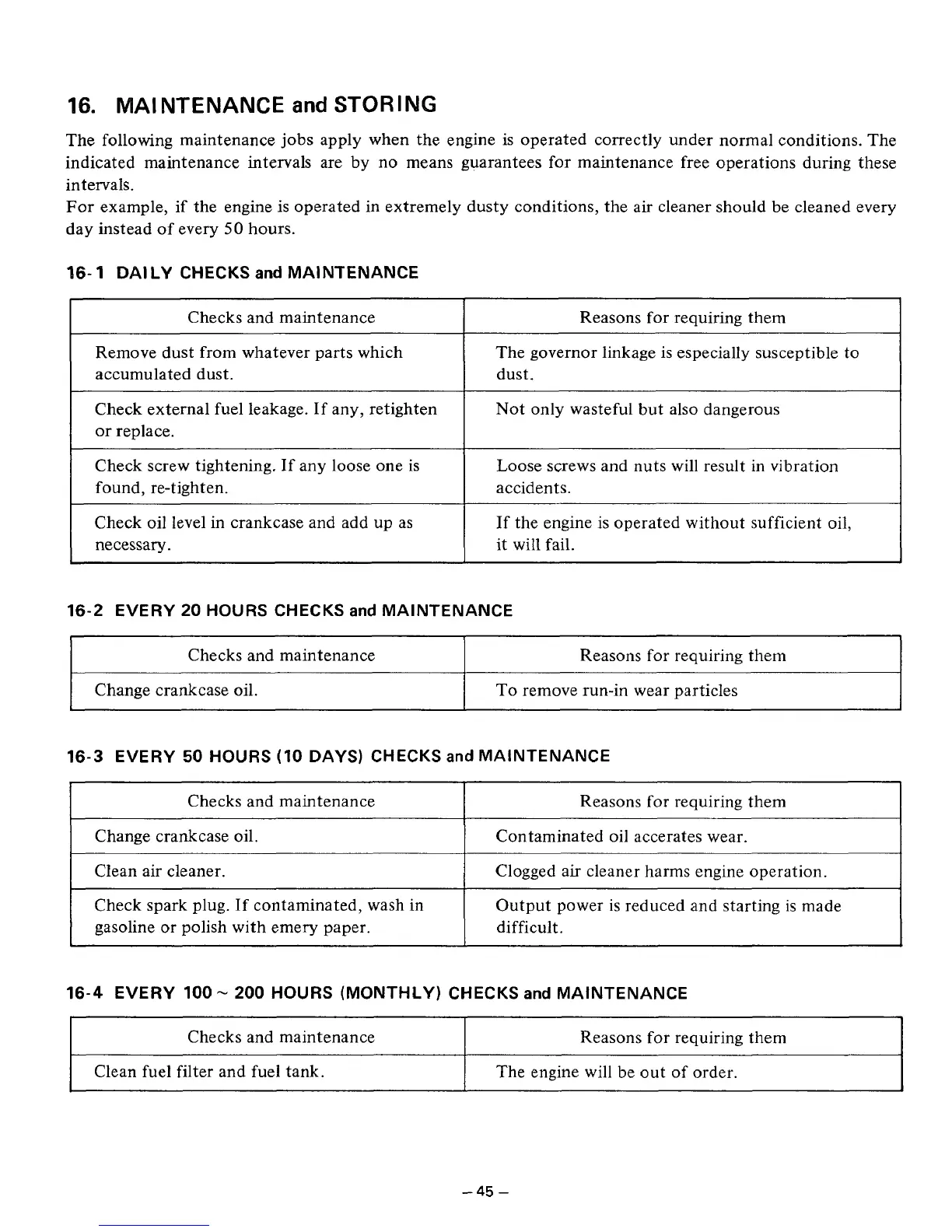

The following maintenance jobs apply when the engine is operated correctly under normal conditions. The

indicated maintenance intervals are by no means guarantees for maintenance free operations during these

intervals.

For example, if the engine is operated in extremely dusty conditions, the air cleaner should be cleaned every

day instead of every

50

hours.

-

16-

1

DAILY CHECKS and MAINTENANCE

Checks and maintenance

Reasons for requiring them

Remove dust from whatever parts which

accumulated dust.

The governor linkage is especially susceptible to

dust.

~ ~~ ~ ~~

Check external fuel leakage. If any, retighten

or replace.

Check screw tightening. If any loose one is

found, re-tighten.

Not only wasteful but also dangerous

Loose screws and nuts will result in vibration

accidents.

Check oil level in crankcase and add up

as

it will fail.

necessary.

If the engine

is

operated without sufficient oil,

L

16-2 EVERY 20 HOURS CHECKS

and

MAINTENANCE

I

1

Checks and maintenance Reasons for requiring them

Change crankcase

oil.

To

remove run-in wear particles

16-3 EVERY

50

HOURS

(10

DAYS) CHECKS

and

MAINTENANCE

I

Checks and maintenance

I

Reasons for requiring them

I

Change crankcase

oil.

~ ~~

I

Contaminated oil accerates wear.

I

I

Clean air cleaner.

1

Clogged air cleaner harms engine operation.

I

Check spark plug. If contaminated, wash in

gasoline or polish with

emery

paper.

Output

power

is reduced and starting

is

made

difficult.

16-4

EVERY

100

-

200

HOURS (MONTHLY) CHECKS and MAINTENANCE

Checks and maintenance

Reasons for requiring them

Clean fuel filter and fuel tank.

The

engine will be out of order.

-45

-

Loading...

Loading...