5-4-6

MAIN BEARING COVER

Install the main bearing cover

to

the.crankcase.

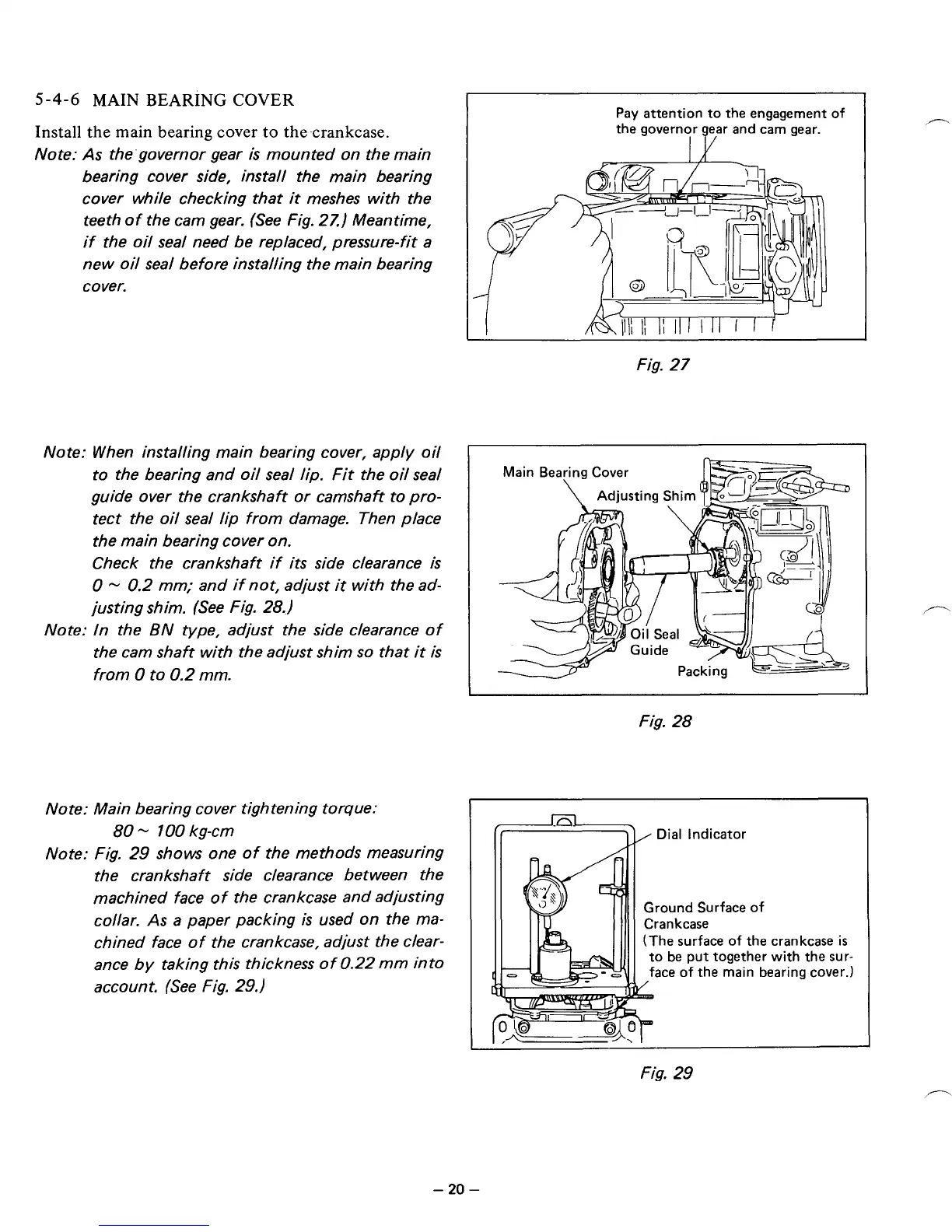

Note:

As

the'governor gear

is

mounted on the main

bearing cover side, install the main bearing

cover while checking that

it

meshes with the

teeth

of

the cam gear. (See Fig. 27.) Meantime,

if

the oil seal need be replaced, pressure-fit a

new oil seal before installing the main bearing

cover.

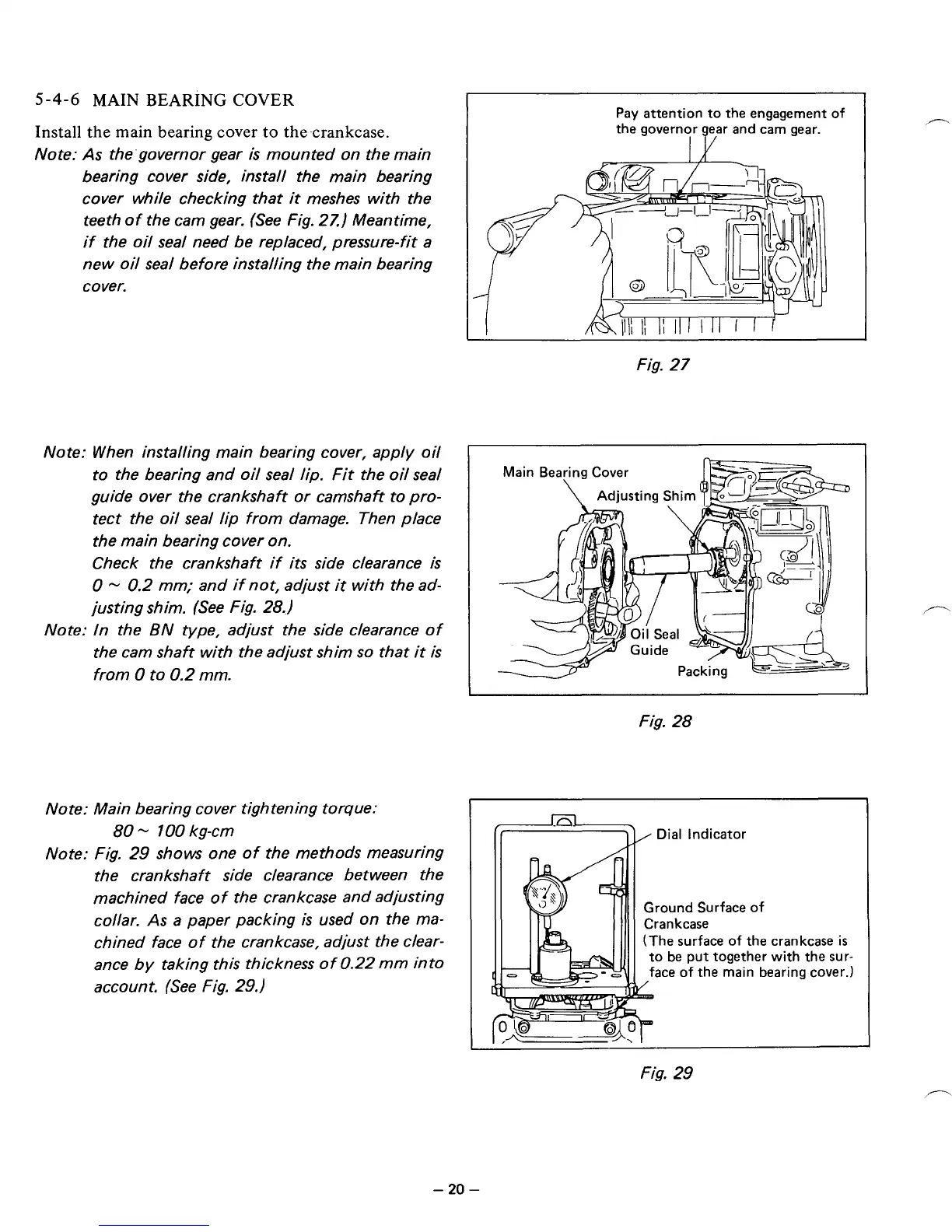

Note: When installing main bearing cover, apply oil

to the bearing and oil seal

lip.

Fit the oil seal

guide over the crankshaft

or

camshaft to

pro-

tect the oil seal lip from damage. Then place

the main bearing cover

on.

Check the crankshaft

if

its

side clearance

is

0

-

0.2

mm; and if not, adjust

it

with the ad-

justing shim. (See Fig. 28,)

Note: In the

BN

type, adjust the side clearance of

the cam shaft with the adjust shim

so

that

it

is

from

0

to

0.2

mm.

Note: Main bearing cover tightening torque:

Note: Fig.

29

shows one of the methods measuring

the crankshaft side clearance between the

machined face

of

the crankcase and adjusting

collar.

As

a paper packing

is

used

on

the ma-

chined face of the crankcase, adjust the clear-

ance

by

taking this thickness of0.22

mm

into

account. (See Fig.

29.)

80

-

100

kg-cm

-1

Pay attention to the engagement of

the governor ear and cam gear.

It

Fig.

27

Fig.

28

1

(*-*

Dial Indicator

Ground Surface

of

(The surface

of

the crankcase

is

to be put together with the sur-

face of the main bearing cover.)

Fig.

29

-

20

-

Loading...

Loading...