5-4

HOW

TO

REASSEMBLE

5-4-1

PRECAUTION IN REASSEMBLY

Every and each part should be cleaned thoroughly. Especially, pay utmost care and attention to the cleanliness of the

piston, cylinder, crankshaft, connecting rod and bearings.

Scrape completely off carbons from the cylinder head and the upper part of the piston; especially the carbon adhered

in the groove of the piston ring should be carefully and completely taken out.

Carefully check the lip portion

of

every oil seal.

If

faulty one is found, replace it without any hesitation.

Apply enough

oil

to the lip portion

of

the

oil

seal when reassembling.

Replace all the gaskets with new ones.

Replace the key, pin, bolt, nuts, etc. with new one, if necessary.

Whenever tightening torque is specified, conform

to

the specified figures.

Apply oil

to

the revolutionary parts and friction surfaces, when reassembling.

Check and adjust the clearances

of

various portions and then reassemble.

When some main portions are assembled in the course

of

reassembling, turn or move the gadgets by hand and pay at-

tention to the frictional noise and resistance.

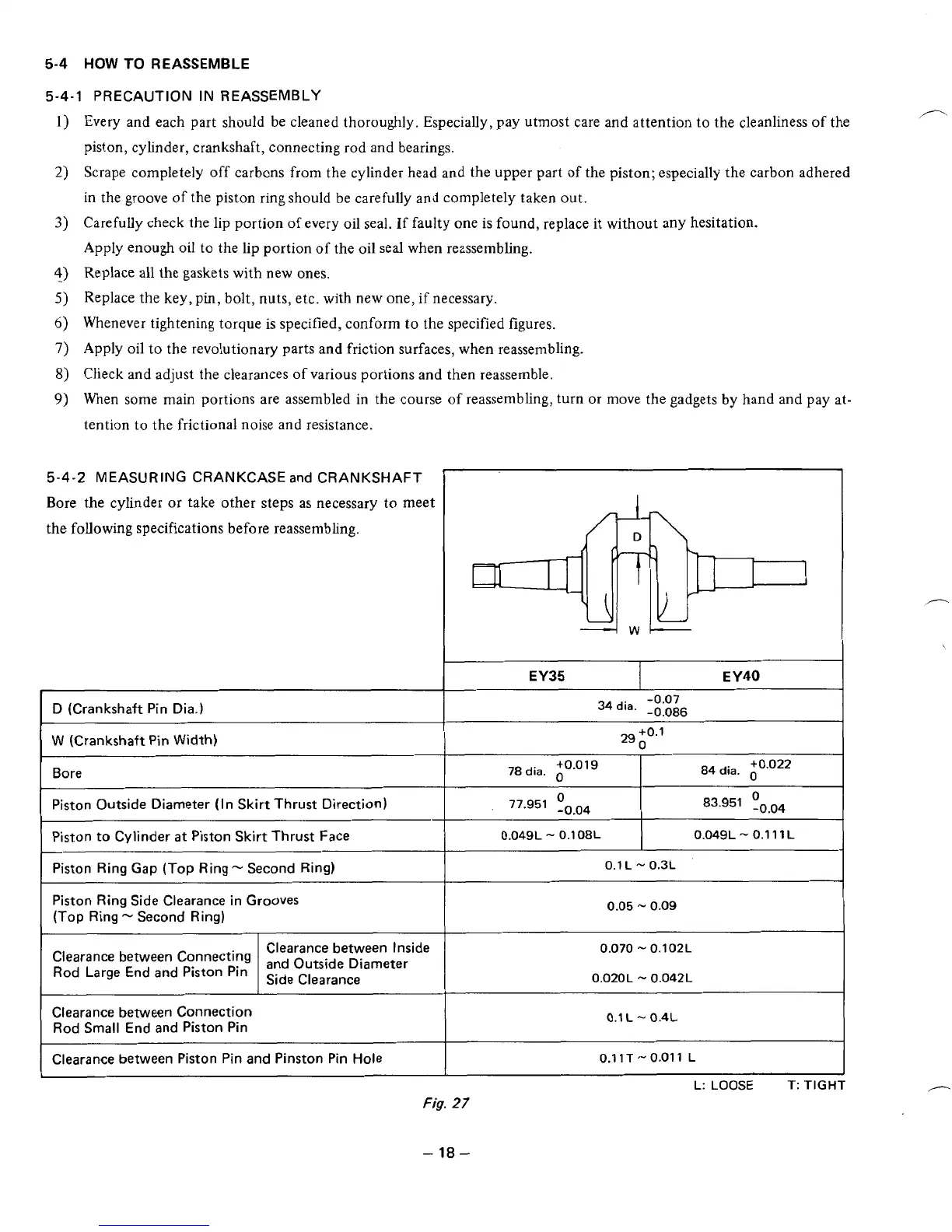

5-4-2

MEASURING CRANKCASE and CRANKSHAFT

Bore the cylinder or take other steps as necessary

to

meet

the following specifications before reassembling.

EY35

E

Y40

I

W

(Crankshaft

Pin

Width)

I

29

+0.1

0

Bore

Piston Outside Diameter (In Skirt Thrust Direction)

78

dia.

40.019

I

84

dia.

,,

+0.022

I

Piston

to

Cylinder

at

Piston Skirt

Thrust

Face

I

0.049L

-

0.1

08L

1

0.049L

-

0.1

11

L

Piston Ring Gap (Top Ring

-

Second Ring)

I

Piston Ring Side Clearance in Grooves

(Top Ring

-

Second Ring)

Clearance between Connecting

Rod Large End and Piston Pin

and

Outside

Diameter

Clearance between Inside

Side

Clearance

0.1

L

-

0.3L

0.05

-

0.09

Clearance between Connection

Rod Small End and Piston Pin

Clearance between Piston Pin and Pinston Pin Hole

0.070

-

0.102L

0.020L

-

0.042L

0.1

L

-

0.4L

0.1

1T

-

0.01

1

L

r'

L:

LOOSE

Fig.

27

-

18

-

Loading...

Loading...