3)Notice

①CleantheCARBURETORusingcleangasolinebeforedisassembly.

②Disassembleorreassemblereferringtothedealdrawing.

③DonotdisassembletheTHROTTLEVALVEASSYandPUMPBODYASSY.

4)Disassemblyandreassemblyprocedure

①Removethescrew(PUMPCOVER)andthenthePRIMERPUMPCOVER.Removedustclearlyfrom

thePRIMERPUMPifany.

②RemovethePUMPBODYASSYfromthebody(donotlettheSPRINGmissing).

RemovedustclearlyfromtheINLETSCREENifany.

③RemovetheJETfromthebody.

④RemovetheSCREW(THROTTLECOLLAR)andthenTHROTTLEVALVEASSYfromthebody.

⑤ReassembletheJETandSPRINGfirmlywhenreassemblingtheCARBURETOR.

5)Checkingprocedure

①Cleanthebodyusinggasolineandblowitclearlywithcompressedair.

②TesttheJETfordustandcorrosion.Thedustneedscleaningandblowingwithcompressedair

andcorrosionreplacingwithnewone.(Note:ThenewJETshouldhavethesamenumberwiththat

oftheoldone.)

③TesttheGASKETSfordeformationandbreakage.Replacebadgasketswithnewonesifany.

④ThePUMP(DIAPHRAGM)shouldnotbehardenedordamaged.

⑤TheINLETVALVEandtheOUTLETVALVEshouldbeflatandnotbent.

⑥TheDIAPHRAGMASSYshouldbefreeofanyhardening,damageorbend.

⑦AftercleaningthePUMPBODYASSY,testitfordeformationoftheMETERINGLEVERandMETERING

LEVERSPRING,heightoftheMETERINGLEVER,duststucktotheINLETSCREEN,andVALVEleakage,

etc.TochecktheMAINCHECKVALVEforitscorrectoperation,placeavinylorrubberhoseat

itsendontheCHECKVALVEportionfromtheJETsideandbreathitattheotherend.

Ifyoucannotbreatheitandvalvecloseswhenyoubreatheitin,itworkscorrectly.Ifnot,

immerseitingasolineforabout10minutesandthenrepeattheproceduredescribedabove.

IftheVALVEcannotbefixedevenbydoingthis,replaceitwithanewPUMPBODYASSY.

(Note:DonotblowtheMAINCHECKVALVEwithcompressedair.Ifyouuseanairgun,keepit

about30cmawayfromthevalvewhenthecompressedairhasapressureof6kg/cm

2

).

⑧TestthePRIMERPUMPforanyhole,breakageandabnormalhardening.Makesurethatthe

COMBINATIONVALVEworkscorrectly.

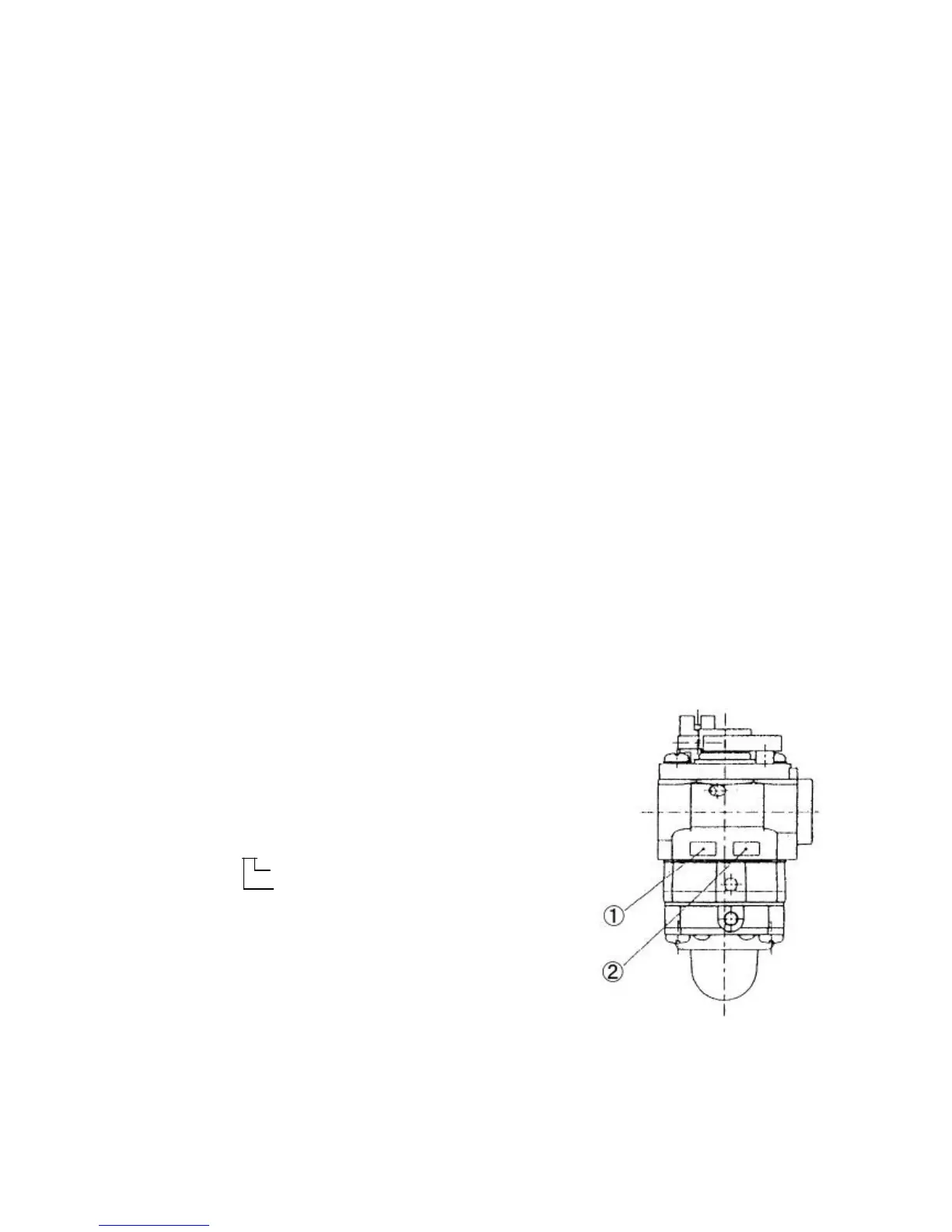

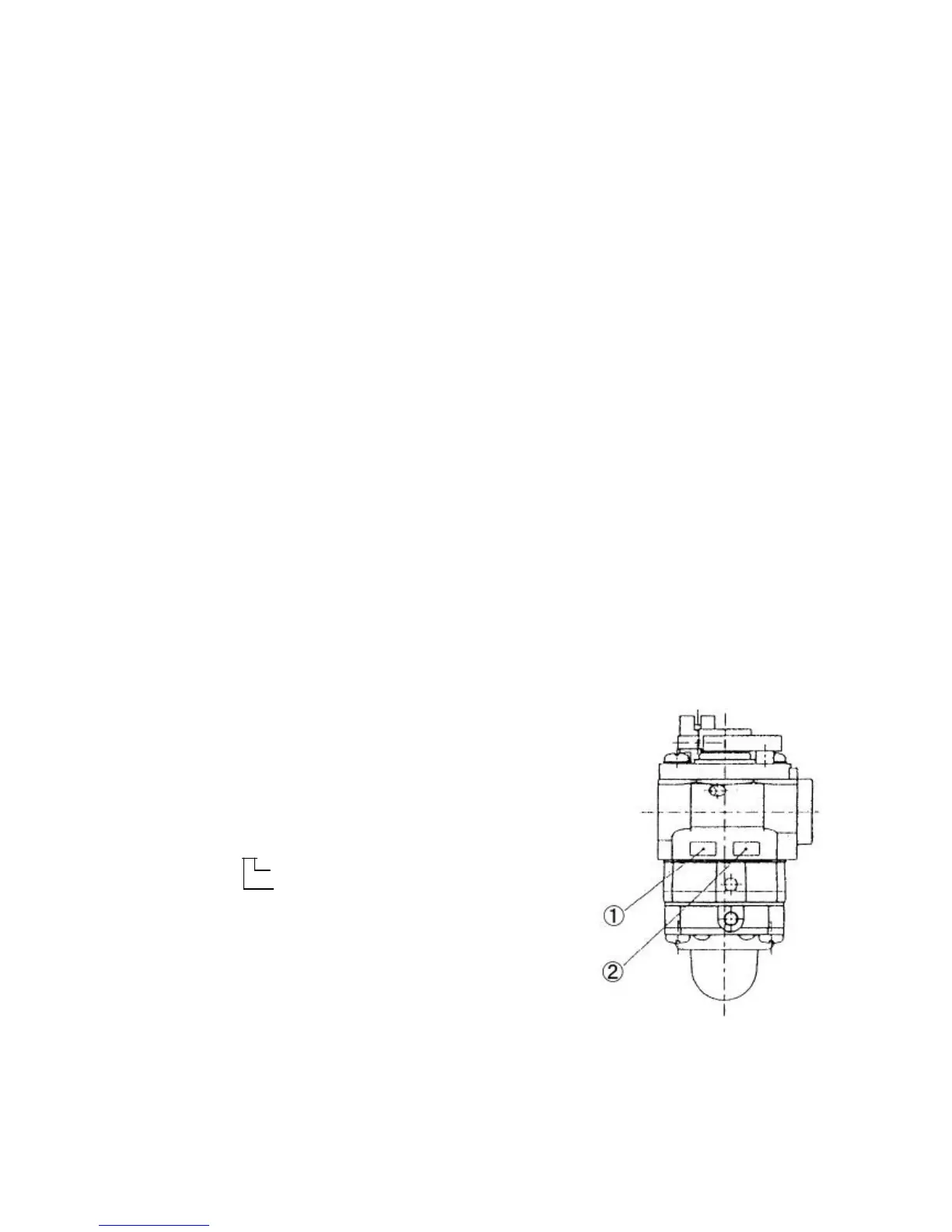

6)MarksonCARBURETOR

MarksarestampedontheCARBURETORasshownintherightfigure:

①ModelNo.

②Dateofmanufacture

Example)①:WYK260

②:630(July24toJuly30,2006)

Week30 (whatweeknumberintheyear)

Lastdigitoftheyear

Loading...

Loading...