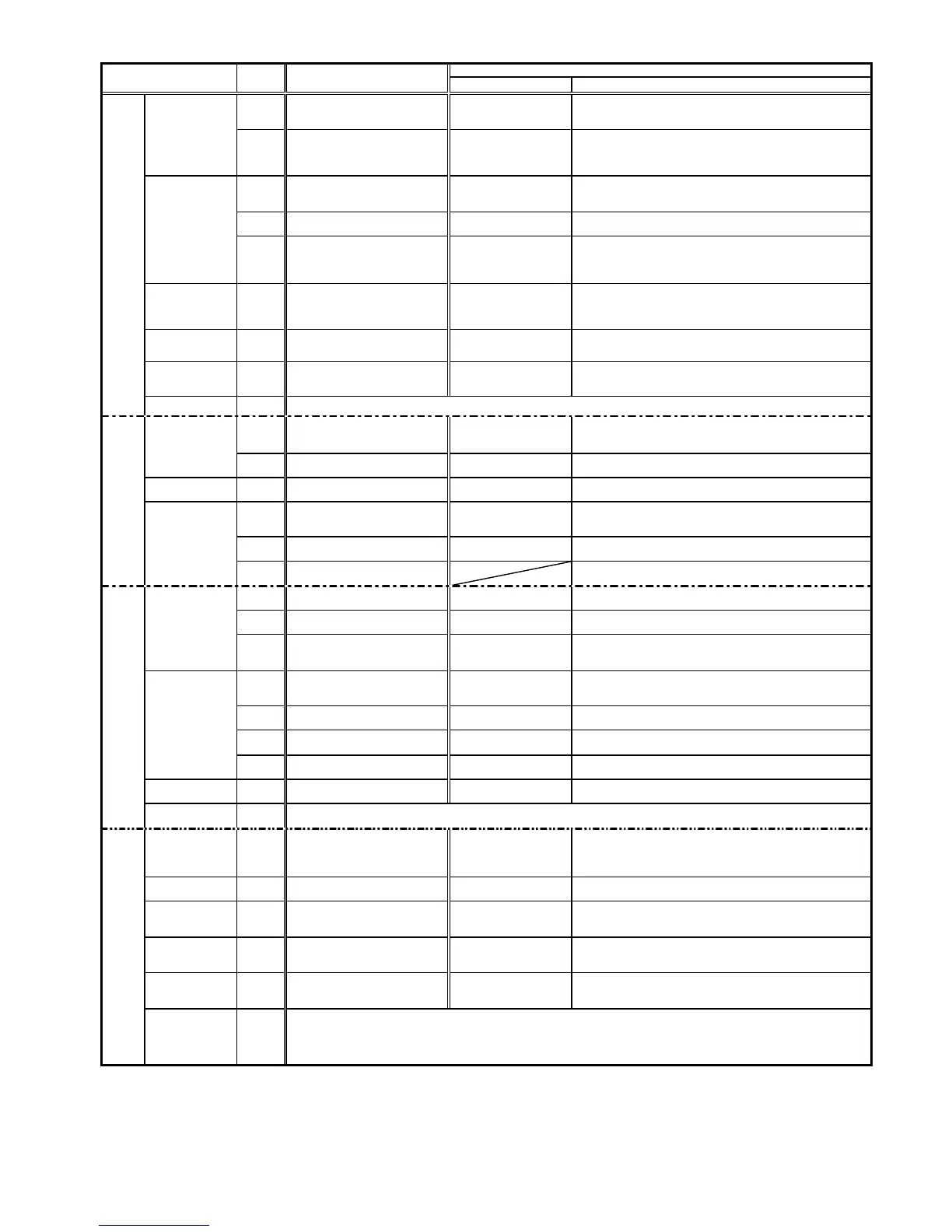

54

Actiontobedone

Trouble Workorder

Pointtobechecked

Withoutproblem Withproblem

6−5

Doesair-fuelmixtureleakfromthemating

facesoftheCARBURETOR,INSULATOR

etc.?

No

6−6

Investigatetheleakageandcorrectit.Repla

cethepacking,etc.withanewoneif

DisassembletheCARBURETORtotestit

forthecomponentpartsbeingclogged

upand/ordeteriorated.

NotroubleintheCARBURETOR

6−7

CleantheinsideoftheCARBURETOR.Replacewearoutparts,sucha sthe

diaphragmwithnewones.ReplacetheCARBURETORwithanewoneif

necessary.

See P.48〜49

6−7

RemovetheROCKERCOVERtocheck

whetherthevalueclearanceis

within0.08-0.40(criterion:0.15).

Thevalveclearanceiswithinthe

criterion

6−8

Adjustthevalveclearanceat0.15.

See P61〜62

6−8

TesttheCAMGEARforanyablationofthe

camtop.

Noablation

6−9

AnyablationoftheCAMtopneedsreplacingtheCAMGEARwithanewone.

See P30〜32(disassemble)、P43〜45(reassemble)

Valvetrain

6−9

IstheCAMGEARtimingright?(Thetiming

markoftheCAMGEARfaces

downverticallywhenthepistonis

atthetopdeadcenter.)

Yes

6−10

CorrectthebadCAMGEARtiming.

See P43〜45

Insufficientcompression 6−10

PulltheRECOILSTARTERtocheckfor

properwhiletheen

inthecombustionchamberDoesthe

compressionseemtobeinsufficient?

No

6−11

Compressedinsufficiently.Returntoworkorder4 −2togettheproper

compressioninthecombustionchamber.

PlugandIgnition 6−11

DoesthePLUGignitesufficiently?

Yes

6−12

Theplugignitesinsufficiently.Returntowork2 −3togetthesufficientspark.

Isthecoolingairpassagecloggedupatits

inletwithdart?Hastheengineover-

consequently?

No

6−13

Removethedarttogetthegoodcoolingairflow.

Pooraccelerationandoutputshortageofengine

Unknowncase 6−13

Askaservicemanwithoutknowncauseoftheenginetrouble(pooraccelerationand/oroutputshortage).

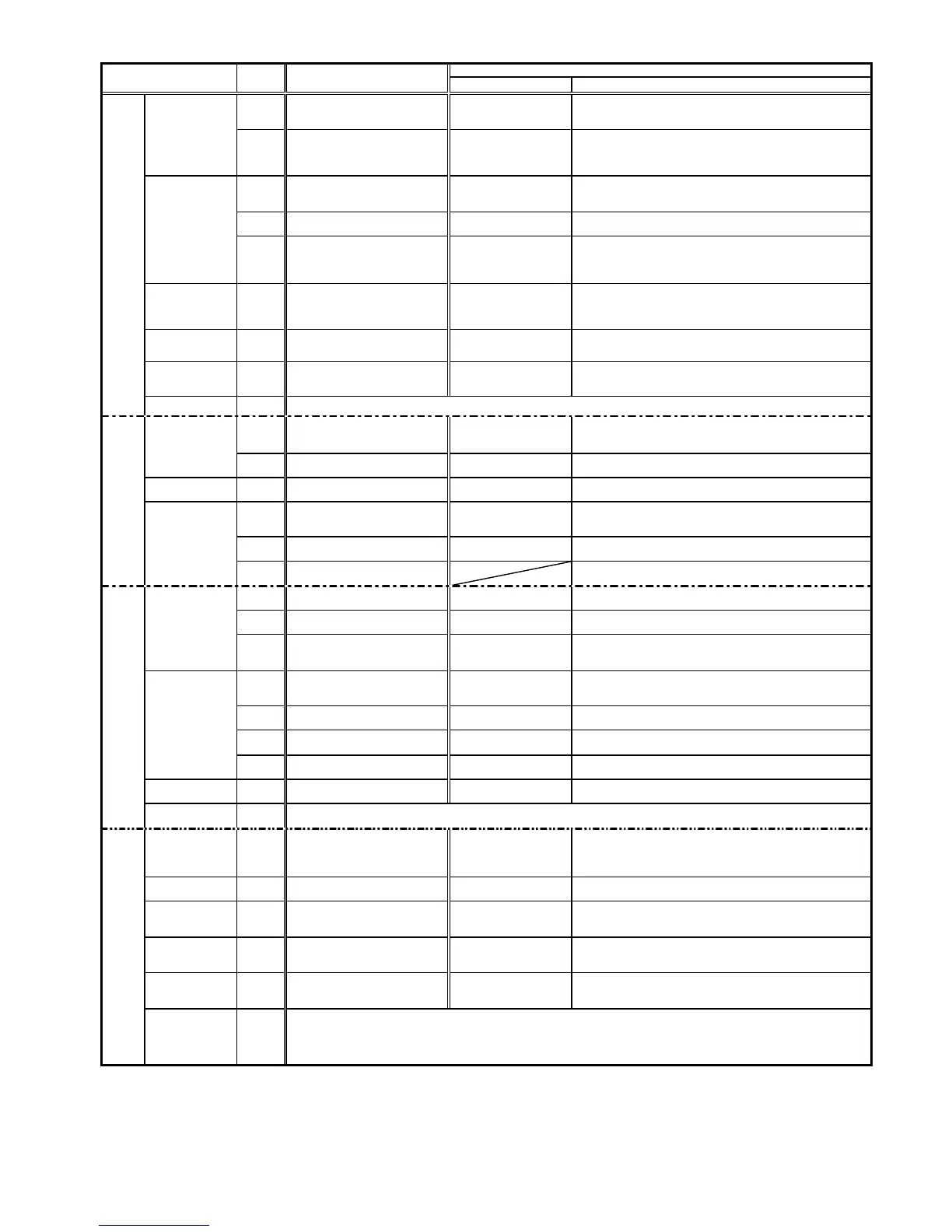

7−1

Wasitconfirmedatthepre-operation

checkthattheengineoiltankwasfilled

withengineoilof220cc?

Yes

7−2

Iftheoillevelisover220ccdraintheoilfromtheengineoiltankorifless70cc

filltheoiltankwithengineoil,tothelevelof220cc.

See P60

Oilcare

7−2

Istheengineoilconsumedover5ccan

hour?

No

Yes

7−3

Others 7−3

theengineoilleakfromtheOILCAP,

etc.?

No

7−4

Performworkorders8 −1 ,8 −2and 8 −5whenafairylargeamountof

leakedoilisfoundaroundtheCAP,OIL.

7−4

Disassemblethewholeengine.Testthe

CYLINDERboreformarkedablati

damage.

Noablationordamaged

7−5

Markedablationand/ordamageneedsreplacingtheCYLINDERwithanewone.

TestthePISTONformarkedabrasion

and/ordamage.

Noablationordamaged

7−6

Markedablationand/ordamageneedsreplacingthePISTONwithanewone.

Abrasionanddamage

TestthePISTONRINGformarked

abrasion.

MarkedabrasionneedsreplacingthePISTONRINGwithanewone.

See P36(disassemble)、P38(reassemble)

8−1

IstheCAP,OILtightened?

Yes

8−2

TightentheCAP,OIL.

8−2

Wastheengineoilspilledontothe

equipmentatfeedingand/orchangingoil?

No

8−3

Becarefulnottospilltheengineoilaroundtheequipmentatfeedingand/or

changing.Ifspilled,wipeofftheequipment. Oilandenginecare

IstheinsideoftheAIRCLEANERcleaned

beforeoperation?

Yes

8−4

BesuretocleantheinsideoftheAIRCLEANERbeforeoperation.Theinsideof

theAIRCLEANEReasilygetsdirtywiththeengineoil.

See P63

8−4

IsthePLATE,SEPARATORinthe

AIRCLEANERloose?

No

8−5

Ifloose:

? FastentheOILSEPARATORtothebottom,or

? ReplacetheOILSEPARATORwithanewone(6676500600)

8−5

Isthegasket(rubberpacking)

oftheCAP,OILstiff?

No

8−6

Replacethegasketwithanewone(0213229980)

Agasketusedforlongtimeislikelytogetstiff,whichcausesanoilleak.

8−6

Isthegasketusedwiththeoildrainbolt

placed,and/oristhereanycrackonit?

No

8−7

BecarefulnottoloosetheGASKET.

Replacethegasketwithanewoneifcrackonit(0037008000)

Enginecare

8−7

Isanyscrewintheengine

loose?

No

8−8

Tightenloosescrewsagain.

Workingsurroundings

Istheoperationbeingdoneinanunusual

placeand/orworkmethod?

No

8−9

Operatetheequipmentinanappropriatewayfortheoperationinanunusual

placeand/orworkmethod.Askaservicemanfortheappropriateway.

Oilleakfromengine

Unknowncause 8−9

Askaservicemanwithoutknowncauseoftheoilleak.

Oilcare 9−1

Wasitconfirmedatthepre-operation

check

thattheengineoiltankwasfilledwith

engineoilof220cc?

Yes

9−2

Iftheoillevelisover220ccdraintheoilfromtheengineoiltankorifless70cc

filltheoiltankwithengineoil,tothelevelof220cc.

See P60

Workingsurroundings

Istheoperationbeingdoneinanunusual

placeand/orworkmethod?

No

9−3

Operatetheequipmentinanappropriatewayfortheoperationinanunusual

placeand/orworkmethod.Askaservicemanfortheappropriateway.

AIRCLEANERcare

IstheinsideoftheAIRCLEANERcleaned

beforeoperation?

Yes

9−4

BesuretocleantheinsideoftheAIRCLEANERbeforeoperation.

TheinsideoftheAIRCLEANEReasilygetsdirtywiththeengineoil.

See P63

Others 9−4

Drivetheengineatabout7000rpmfor

about3minutes.Hasthewhitesmoke

disappeared?

Yes

No

9−5

Oilconsumption 9−5

Istheengineoilconsumedover5ccan

hour?

No

9−6

Performworkorders7-4orbelowuntiltheproblemoftheexcessoil

consumptioniscorrected.(Excessoilconsumptionmaycausecloudsofwhite

smoke.)

Cloudsofwhitesmokecomeoutofmufflerduring

operation.

Unknowncause 9−6

Cloudsofwhitesmokedonotcomeoutduringoperationwiththeoilconsumptionat5ccorlessanhourandinnormaluse.Checkagainthattheequipment

hasbeeninoperationinanappropriateplaceandworkmethod.Askservicemanforfurtherinformation.

Loading...

Loading...