l

TOLERANCE OF NEWLY INSTALLED PARTS

Thrust directional tolerance between the cylinder and piston skirt

I

0.008L - 0.047 L

I

I

Top ring

I

0.2 L - 0.4L

I

Clearance of piston ring joint Second ring

0.2L - 0.4L

Oil ring

0.05L - 0.25L

Spare rings

Top ring

0.09OL - 0.135L

I

Clearance between piston ring Second ring

, Oil ring

0.06OL - 0.105L

O.OlOL - 0.065L

Spare ring

Clearance between connecting

rod large end and crankpin

Inside and outside diameter

clearance

Side clearance

0.037L - 0.063L

O.lL-0.7L

Clearance between connecting rod small end and piston pin 1 O.OlOL - 0.029L

I

I

Clearance between piston pin and piston pin hole

1 0.009T - O.OlOL

I

Table 10-2

L = Loose T = Tight

NOTE: The clearance between the piston and cylinder is checked by measuring the clearance between the

piston and cylinder skirt.

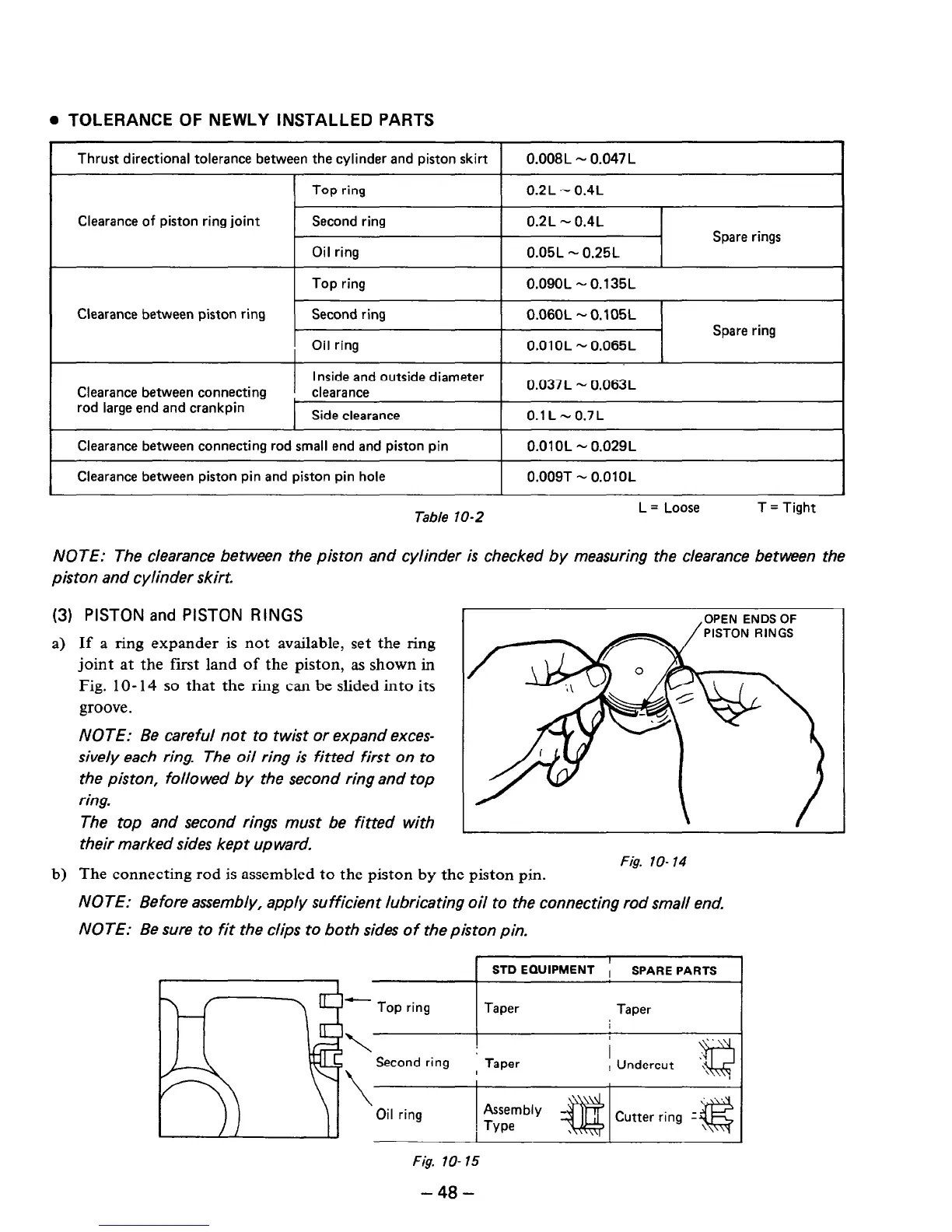

(3) PISTON and PISTON RINGS

a) If a ring expander is not available, set the ring

joint at the first land of the piston, as shown in

Fig. lo- 14 so that the ring can be slided into its

groove.

NOTE: Be careful not to twist or expand exces-

sively each ring. The oil ring is fitted first on to

the piston, followed by the second ring and top

ring.

The top and second rings must be fitted with

their marked sides kept up ward.

OPEN ENDS OF

PISTON RINGS

Fig. IO- 74

. ,

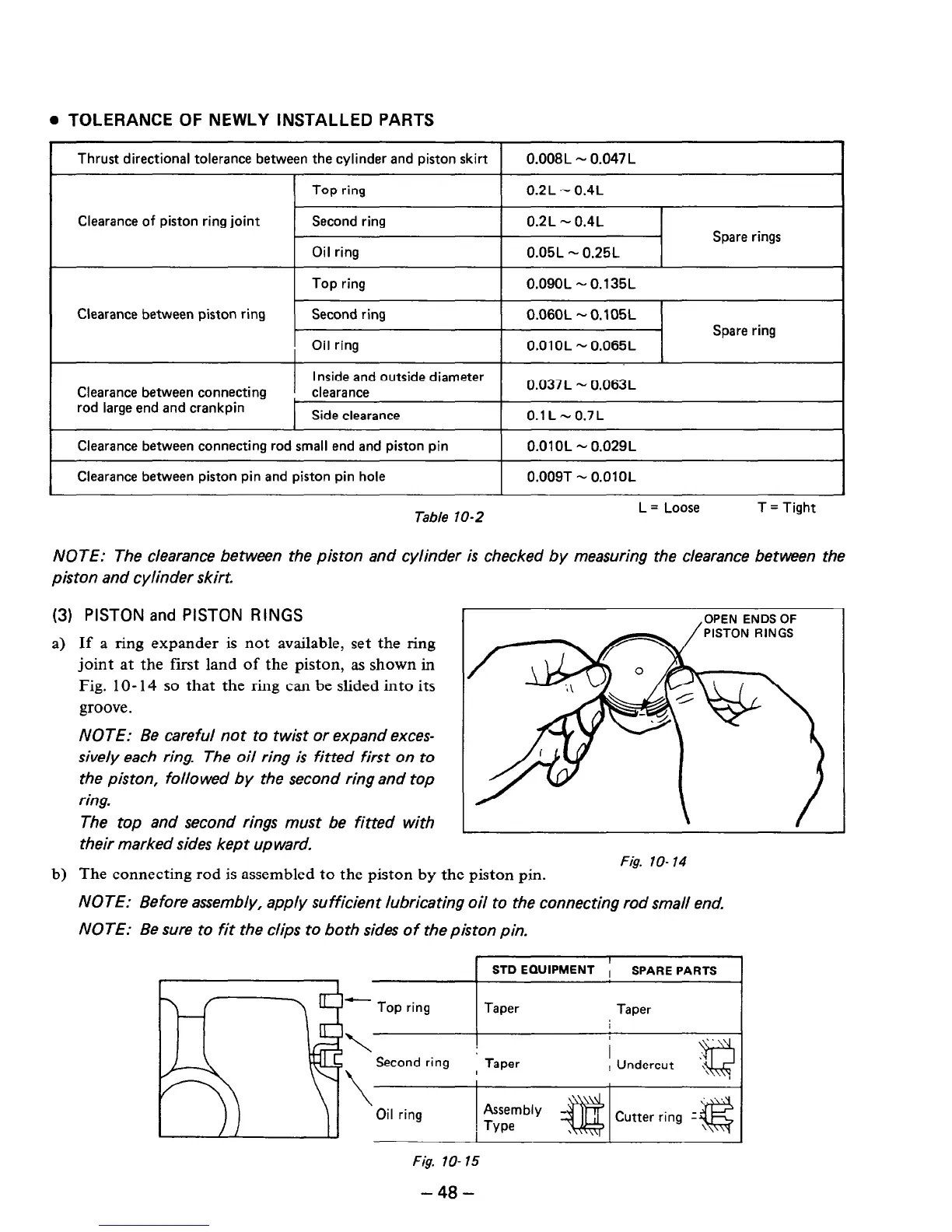

b) The connecting rod is assembled to the piston by the plsron pm.

NOTE: Before assembly, apply sufficient lubricating oil to the connecting rod small end.

NOTE: Be sure to fit the clips to both sides of the piston pin.

a

a

Q

I

STD EQUIPMENT ;

SPARE PARTS

I

- Top ring

Taper

Taper

\

Second ring

\

Oil ring

Fig. lo- 15

- 48 -

Loading...

Loading...