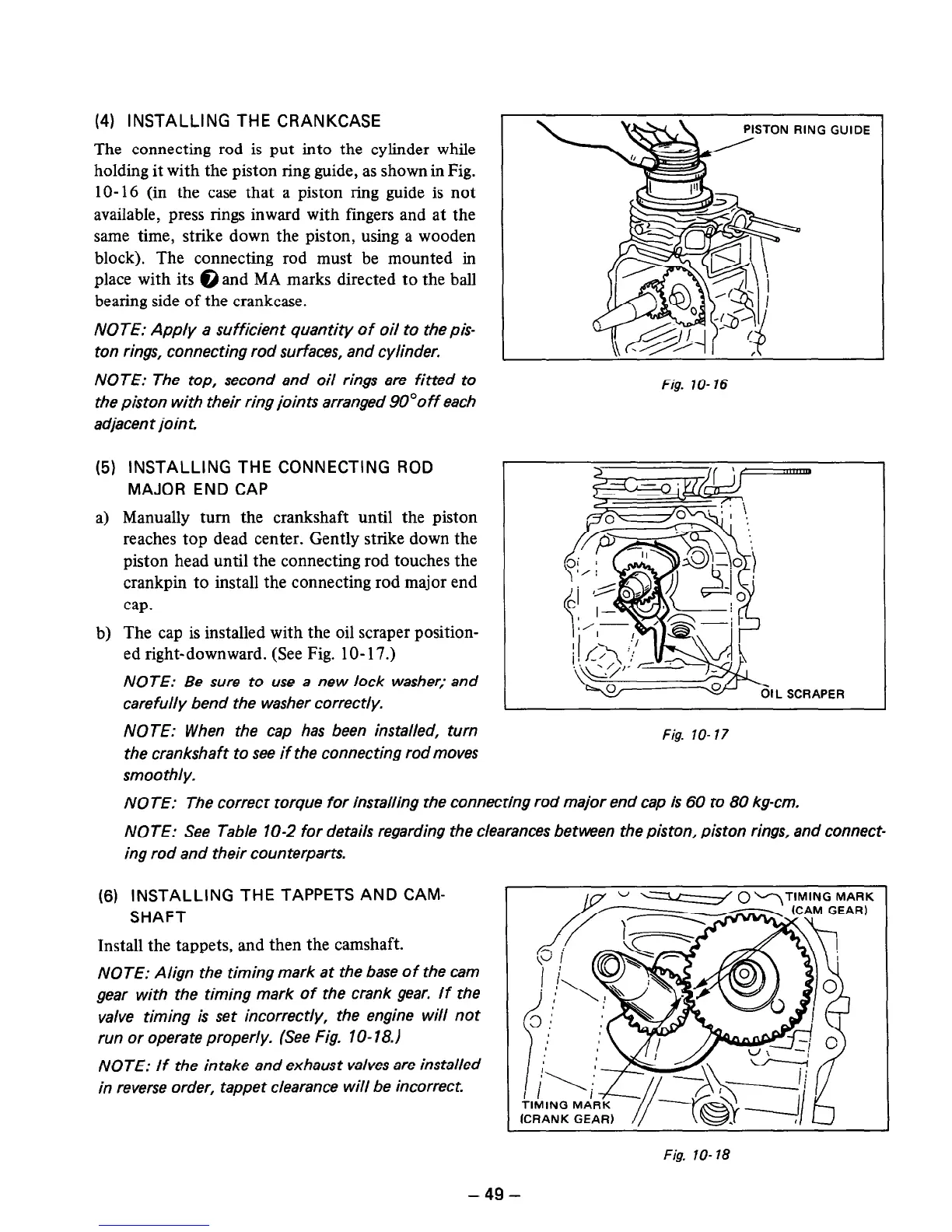

(4) INSTALLING THE CRANKCASE

The connecting rod is put into the cylinder while

holding it with the piston ring guide, as shown in Fig.

lo- 16 (in the case that a piston ring guide is not

available, press rings inward with fingers and at the

same time, strike down the piston: using a wooden

block). The connecting rod must be mounted in

place with its @and MA marks directed to the ball

bearing side of the crankcase.

NOTE: Apply a sufficient quantity of oil to the pis-

ton rings, connecting rod surfaces, and cylinder.

NOTE: The top, second and oil rings are fitted to

the piston with their ring joints arranged 90 ‘0 ff each

adjacent joint.

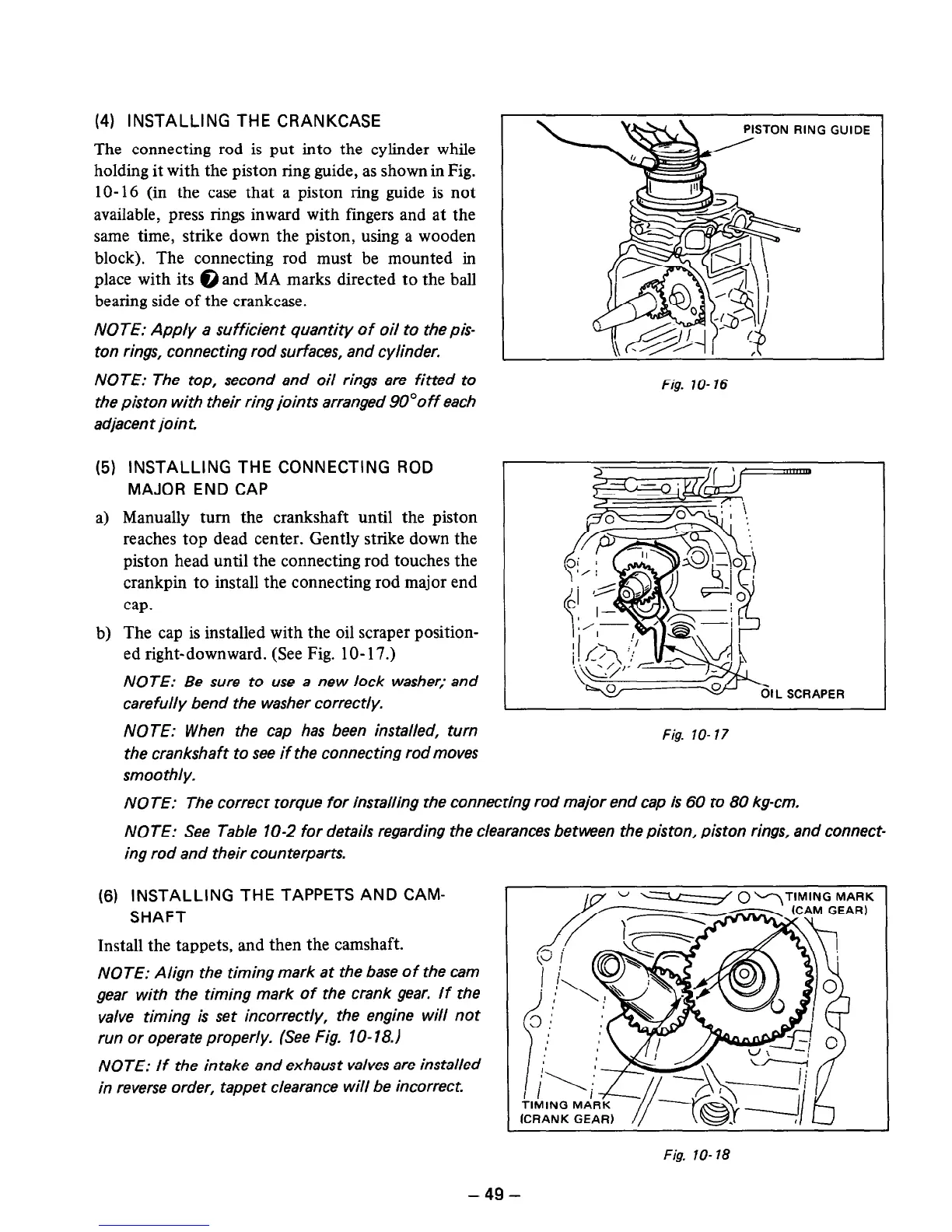

(5) INSTALLING THE CONNECTING ROD

MAJOR END CAP

a) Manually turn the crankshaft until the piston

reaches top dead center. Gently strike down the

piston head until the connecting rod touches the

crankpin to install the connecting rod major end

cap.

b) The cap is installed with the oil scraper position-

ed right-downward. (See Fig. lo- 17.)

NOTE: Be sure to use a new lock washer; and

carefully bend the washer correctly.

NOTE: When the cap has been installed, turn

the crankshaft to see if the connecting rod moves

smoothly.

GUIDE

Fig. lo- 16

Fig. lo- 17

NOTE: The correct torque for installing the connecting rod major end cap is 60 to 80 kg-cm.

NOTE: See Table 10-2 for details regarding the clearances between the piston, piston rings, and connect-

ing rod and their counterparts.

(6) INSTALLING THE TAPPETS AND CAM-

SHAFT

Install the tappets, and then the camshaft.

NOTE: Align the timing mark at the base of the cam

gear with the timing mark of the crank gear. If the

valve timing is set incorrectly, the engine will not

run or operate properly. (See Fig. lo- 18.1

NOTE: If the intake and exhaust valves are installed

in reverse order, tappet clearance will be incorrect.

SEAR)

Fig. lo- 78

-49-

Loading...

Loading...